Cubic crystal phase bismuthyl carbonate photocatalyst with carbonate defect and preparation method thereof

A technology of bismuth oxycarbonate and photocatalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of inability to promote the migration efficiency of photogenerated electrons and the inability to change the excitation path of photogenerated electron transitions, and achieve production The economic cost is low, the promotion of migration and transformation, and the effect of improving the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

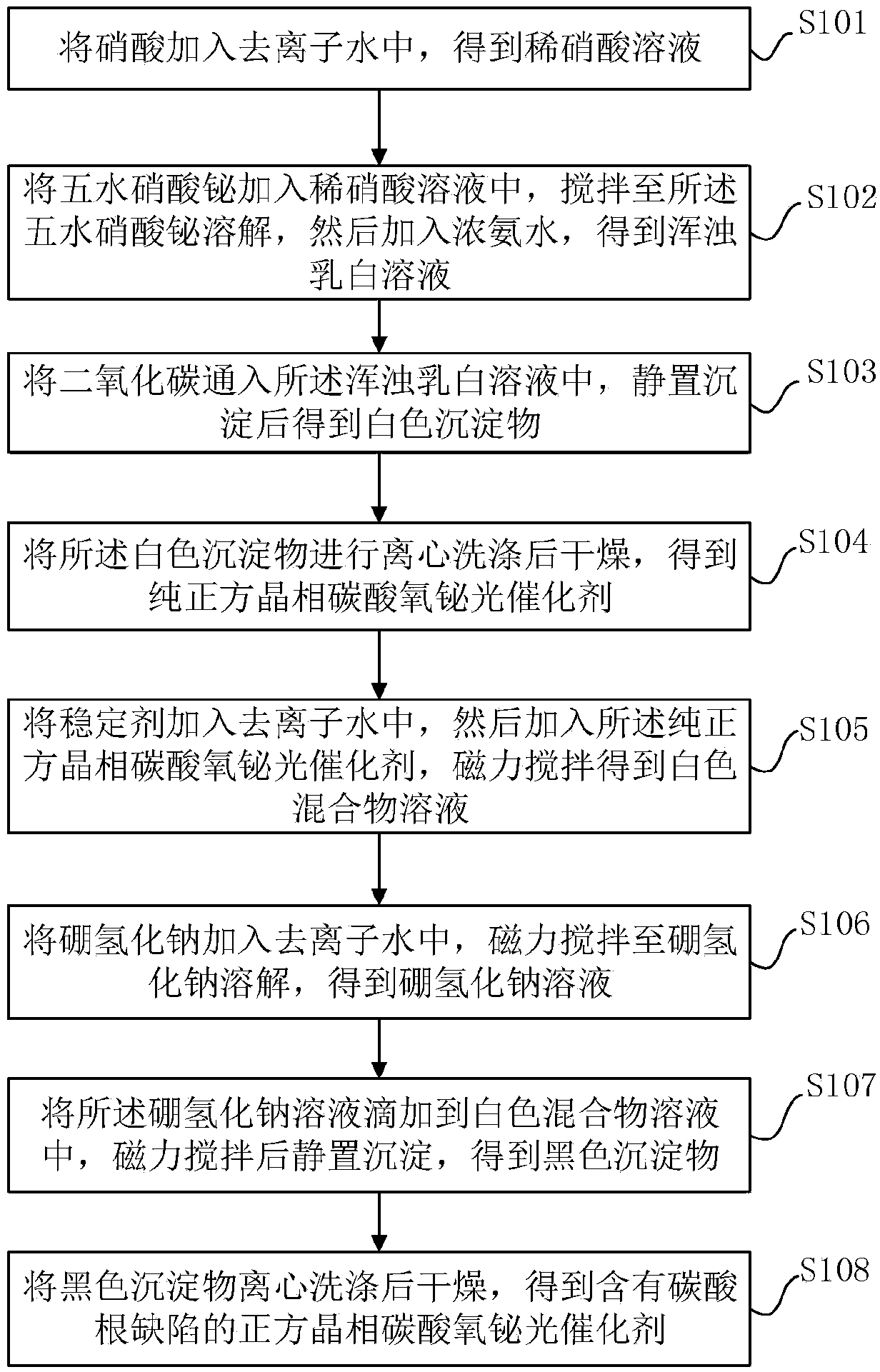

[0054] figure 1 A preparation method of a tetragonal phase bismuth oxycarbonate photocatalyst containing carbonate defects shown in the embodiment of the present application, the preparation method comprises:

[0055] S101, adding nitric acid to deionized water to obtain a dilute nitric acid solution;

[0056] S102, adding bismuth nitrate pentahydrate into the dilute nitric acid solution, stirring until the bismuth nitrate pentahydrate is dissolved, and then adding concentrated ammonia water to obtain a turbid milky white solution;

[0057] S103, passing carbon dioxide into the turbid milky white solution, and obtaining a white precipitate after standing for precipitation;

[0058] S104, the white precipitate is subjected to centrifugal washing and then dried to obtain a pure tetragonal bismuth oxycarbonate photocatalyst;

[0059] S105, adding a stabilizer to deionized water, then adding the pure tetragonal bismuth oxycarbonate photocatalyst, and magnetically stirring to obt...

Embodiment 1

[0091] 1) Add 6.25ml of nitric acid (14.4mol / l) into a 250ml beaker containing 100mL of deionized water to obtain a 0.9mol / L dilute nitric acid solution;

[0092] 2) Add 1.21 g of bismuth nitrate pentahydrate into the dilute nitric acid solution, stir at room temperature for 30 minutes until the bismuth nitrate pentahydrate dissolves, then add 15 mL of concentrated ammonia water and stir for 5 min to obtain a turbid milky white solution;

[0093] 3) Introduce carbon dioxide with a flow rate of 1L / min into the turbid milky white solution, maintain it for 30 minutes, and obtain a white precipitate after standing for precipitation;

[0094] 4) The white precipitate was washed with ethanol and deionized water twice before and after each, and then dried in an oven at 40° C. to obtain a pure tetragonal bismuth oxycarbonate photocatalyst.

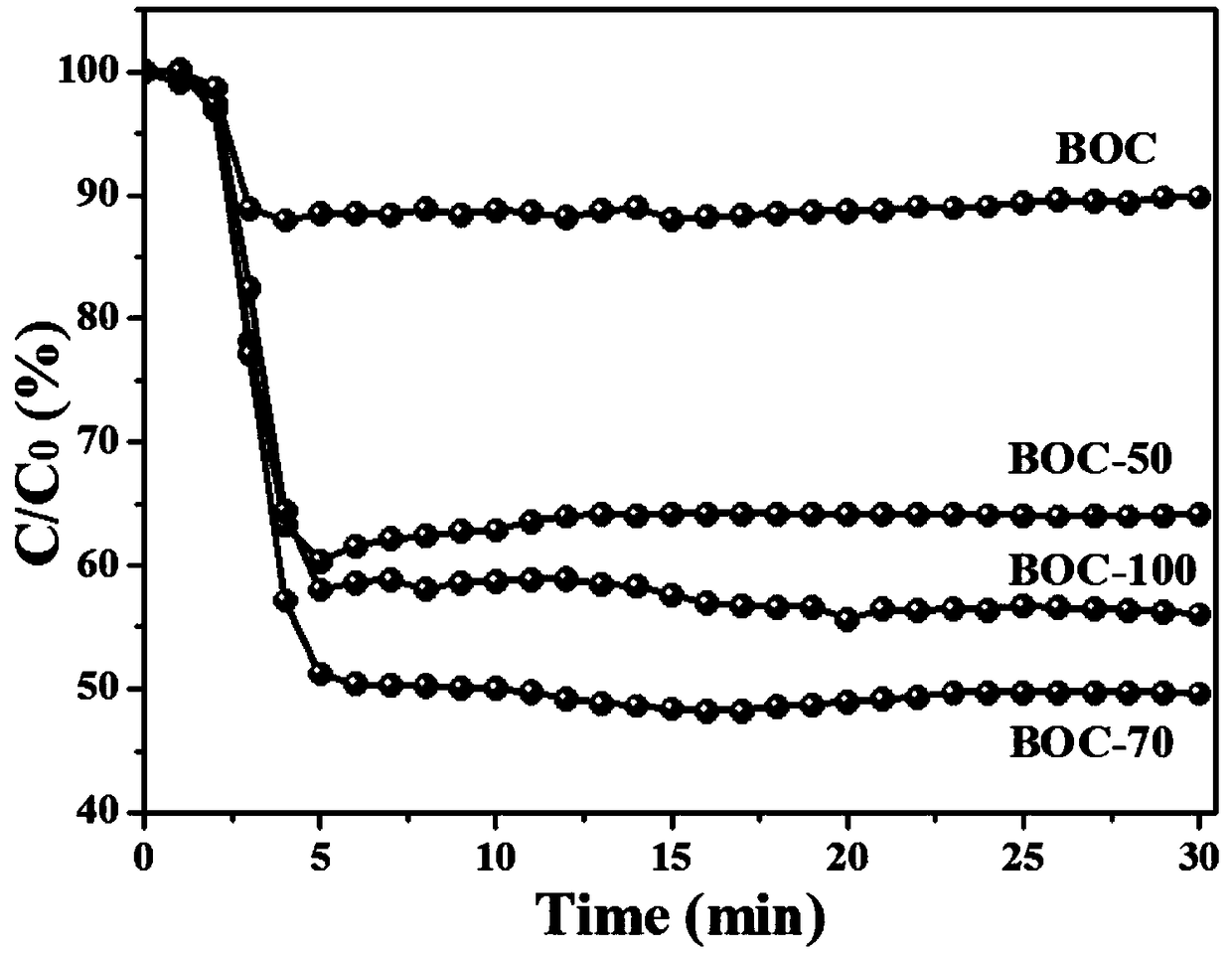

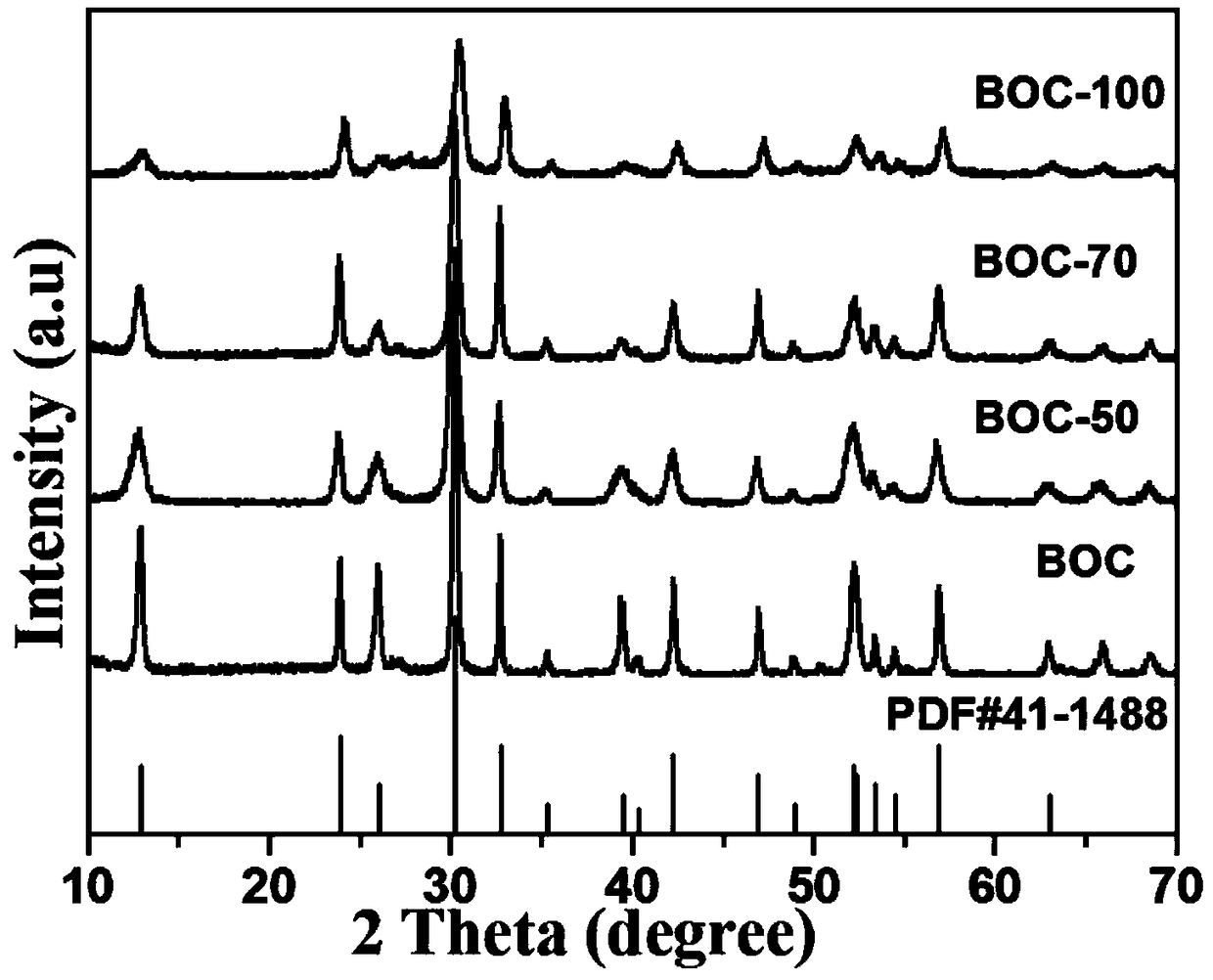

[0095] The pure tetragonal bismuth oxycarbonate photocatalyst prepared in the examples of this application was characterized by XRD, SEM, TEM, HR...

Embodiment 2

[0098] 1) Add 6.25ml of nitric acid (14.4mol / l) into a 250ml beaker containing 100mL of deionized water to obtain a 0.9mol / L dilute nitric acid solution;

[0099] 2) Add 1.21 g of bismuth nitrate pentahydrate into the dilute nitric acid solution, stir at room temperature for 30 minutes until the bismuth nitrate pentahydrate dissolves, then add 15 mL of concentrated ammonia water and stir for 5 min to obtain a turbid milky white solution;

[0100] 3) Introduce carbon dioxide with a flow rate of 1L / min into the turbid milky white solution, maintain it for 30 minutes, and obtain a white precipitate after standing for precipitation;

[0101] 4) washing the white precipitate with ethanol and deionized water twice before and after each, and then drying in an oven at 40°C to obtain a pure tetragonal bismuth oxycarbonate photocatalyst;

[0102] 5) Add 1g of polyvinylpyrrolidone into a 250ml beaker containing 100mL of deionized water, then add 2mmol of pure tetragonal bismuth oxycarbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com