Photovoltaic power generation device capable of efficiently cleaning in linkage way

A photovoltaic power generation and clean technology, applied in the field of solar cells, to achieve the effects of low contact resistance, low single-chip slurry requirement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

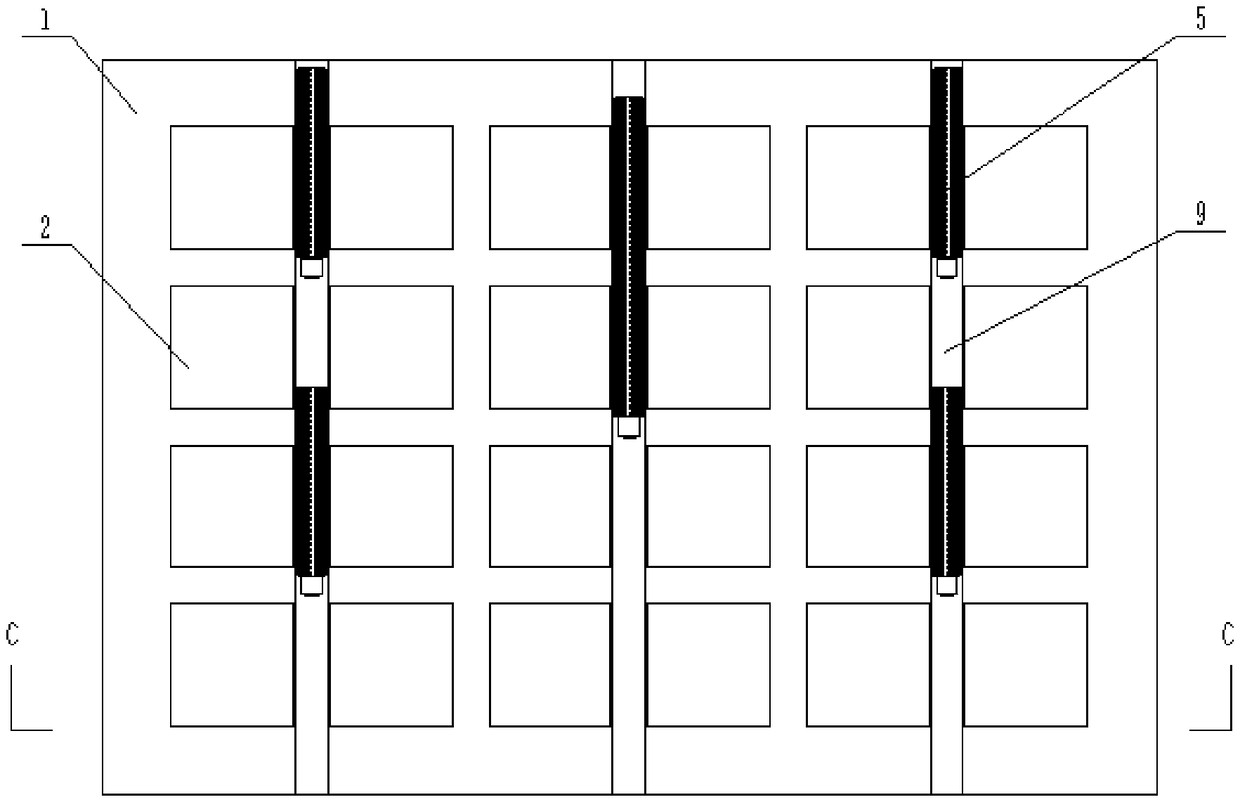

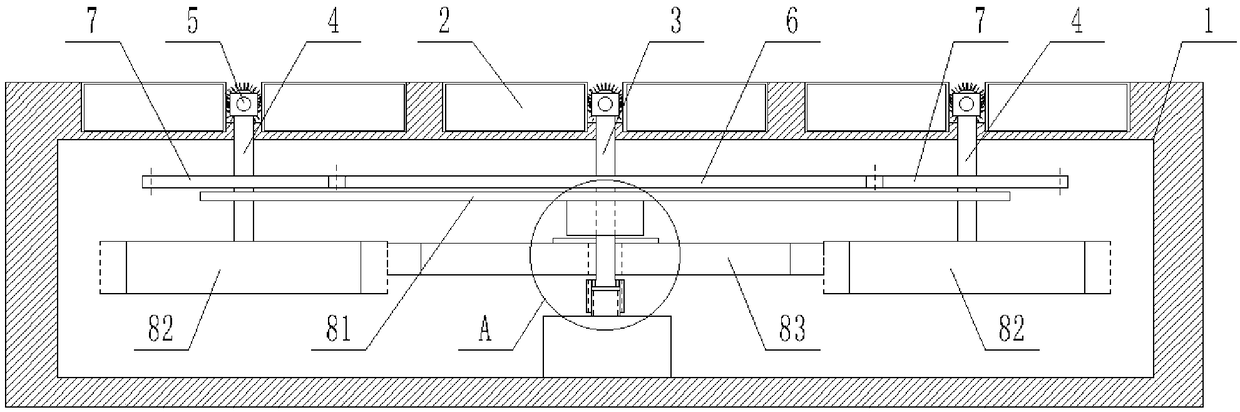

[0026] Embodiment 1 High-efficiency linked clean photovoltaic power generation device I

[0027] Figure 1-6 As shown, a high-efficiency linked and clean photovoltaic power generation device includes a mount 1 on which a plurality of solar cells 2 are installed. The electrode grid line, the silver electrode grid line is obtained by screen printing conductive silver paste I on the silicon wafer, then dried and sintered, and the center of the mounting base 1 is vertically pierced with a main rotating shaft 3, At least one auxiliary rotating shaft 4 is vertically arranged around the main rotating shaft 3, and a plurality of solar cells 2 are evenly distributed between the main rotating shaft 3 and the auxiliary rotating shaft 4, and the main rotating shaft 3 and the auxiliary rotating shaft The rotating shafts 4 are movably installed in the mounting base 1 respectively, and the upper ends of the main rotating shaft 3 and the secondary rotating shaft 4 protrude from the mounting ...

Embodiment 2

[0038] Example 2 High-efficiency linked clean photovoltaic power generation device II

[0039] Figure 1-6 As shown, a high-efficiency linked and clean photovoltaic power generation device includes a mount 1 on which a plurality of solar cells 2 are installed. The electrode grid line, the silver electrode grid line is obtained by screen printing conductive silver paste II on the silicon wafer, then dried and sintered, and the center of the mounting seat 1 is vertically pierced with a main rotating shaft 3, At least one auxiliary rotating shaft 4 is vertically arranged around the main rotating shaft 3, and a plurality of solar cells 2 are evenly distributed between the main rotating shaft 3 and the auxiliary rotating shaft 4, and the main rotating shaft 3 and the auxiliary rotating shaft The rotating shafts 4 are movably installed in the mounting base 1 respectively, and the upper ends of the main rotating shaft 3 and the secondary rotating shaft 4 protrude from the mounting b...

Embodiment 3

[0050] Example 3 High-efficiency linked clean photovoltaic power generation device III

[0051] Figure 1-6 As shown, a high-efficiency linked and clean photovoltaic power generation device includes a mount 1 on which a plurality of solar cells 2 are installed. The electrode grid line, the silver electrode grid line is obtained by screen printing conductive silver paste I on the silicon wafer, then dried and sintered, and the center of the mounting base 1 is vertically pierced with a main rotating shaft 3, At least one auxiliary rotating shaft 4 is vertically arranged around the main rotating shaft 3, and a plurality of solar cells 2 are evenly distributed between the main rotating shaft 3 and the auxiliary rotating shaft 4, and the main rotating shaft 3 and the auxiliary rotating shaft The rotating shafts 4 are movably installed in the mounting base 1 respectively, and the upper ends of the main rotating shaft 3 and the secondary rotating shaft 4 protrude from the mounting b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com