A pump-controlled semi-active heave compensation system and its working method

A heave compensation and semi-active technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., can solve the problem of small hydraulic cylinder compensation range, large winch diameter, active compensation complex and large energy consumption, etc. problems, to achieve the effect of stable work and reduced equipped power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

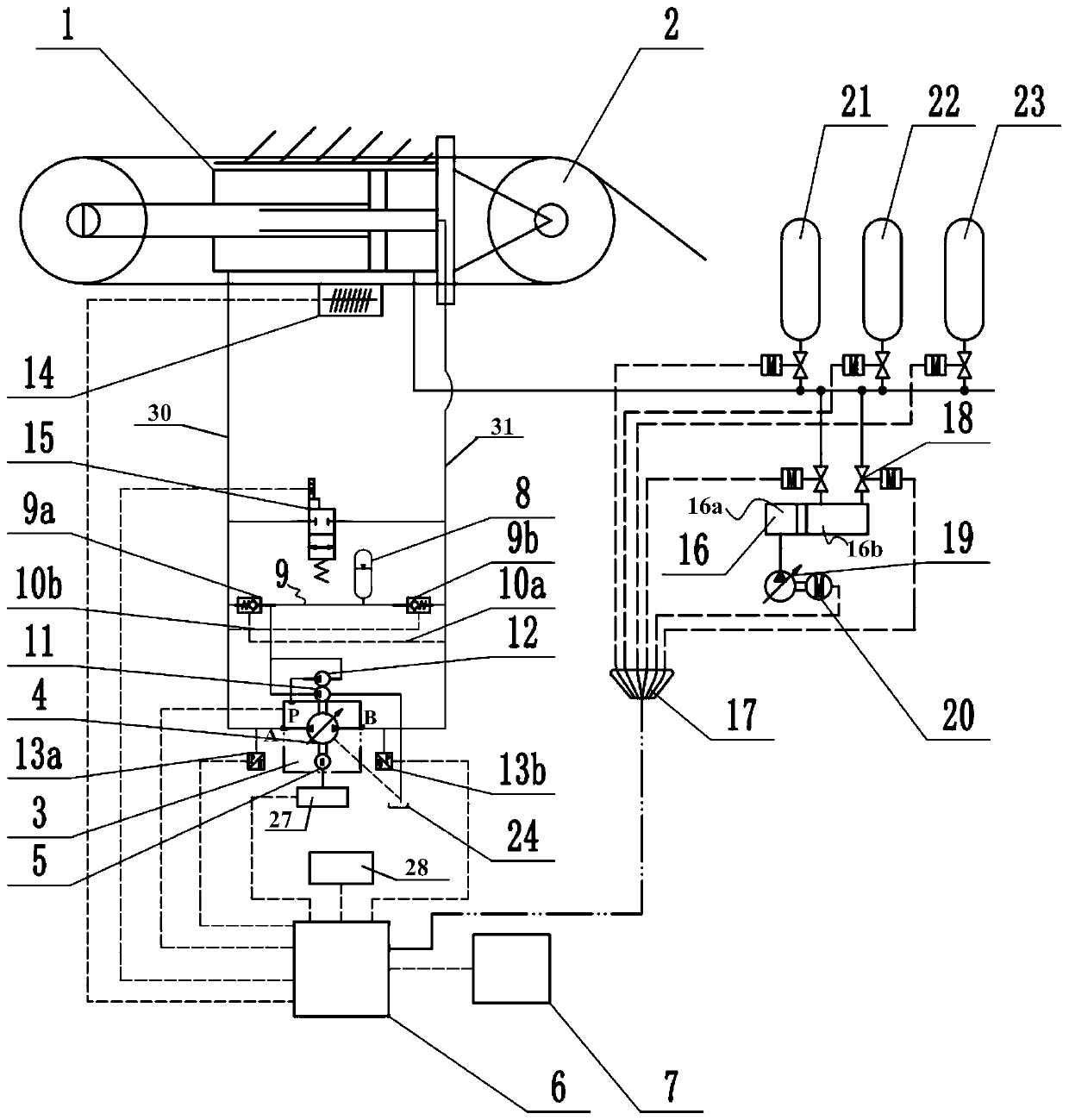

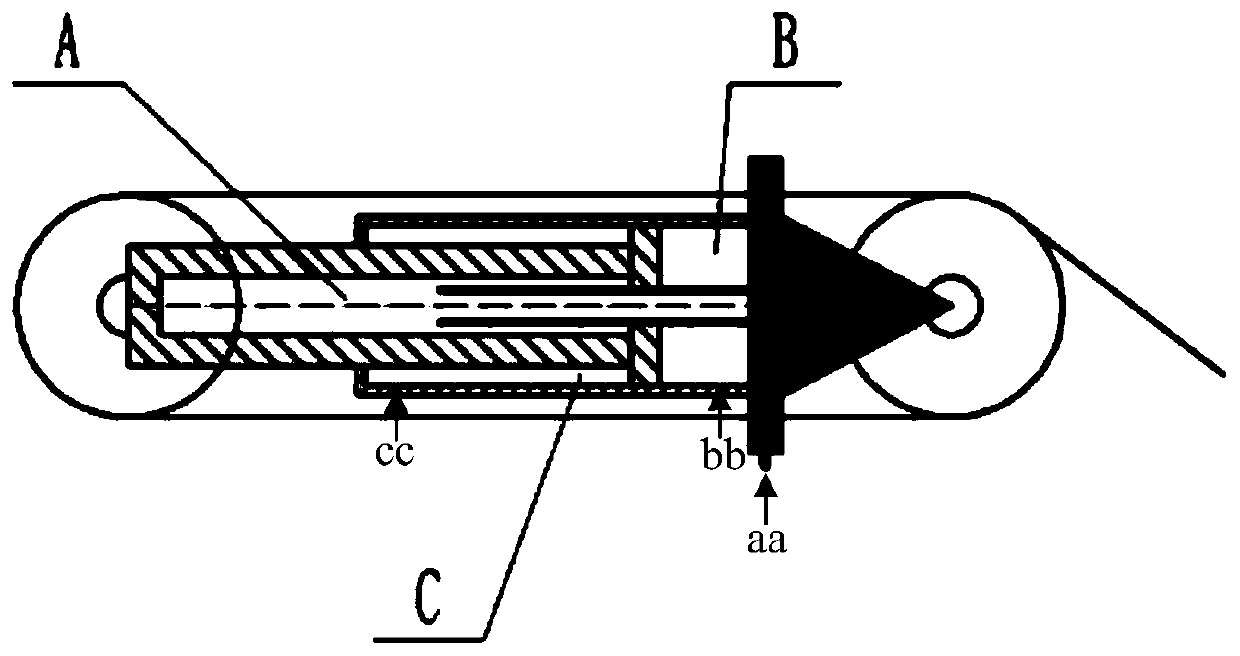

[0058] Such as Figure 1-5 As shown, a pump-controlled semi-active heave compensation system includes a composite hydraulic cylinder 1, a hydraulic power unit 3 and a control unit, wherein:

[0059]The composite hydraulic cylinder 1 is a three-chamber combined hydraulic cylinder. The composite hydraulic cylinder 1 is composed of a double-acting piston hydraulic cylinder and a single-acting plunger hydraulic cylinder. The rodless chamber A chamber and the air chamber B chamber, the rod chamber C chamber and the rodless chamber A chamber are isolated from each other by the piston, and the C chamber is connected to the first oil circuit through the cc port for oil suction and return movement; B The cavity is the air cavity connected to the regulating gas cylinder and the working gas cylinder through the bb port to achieve passive compensation. The A cavity is connected to the second oil circuit through the aa port to perform oil suction and return movements. The composite hydraul...

Embodiment 2

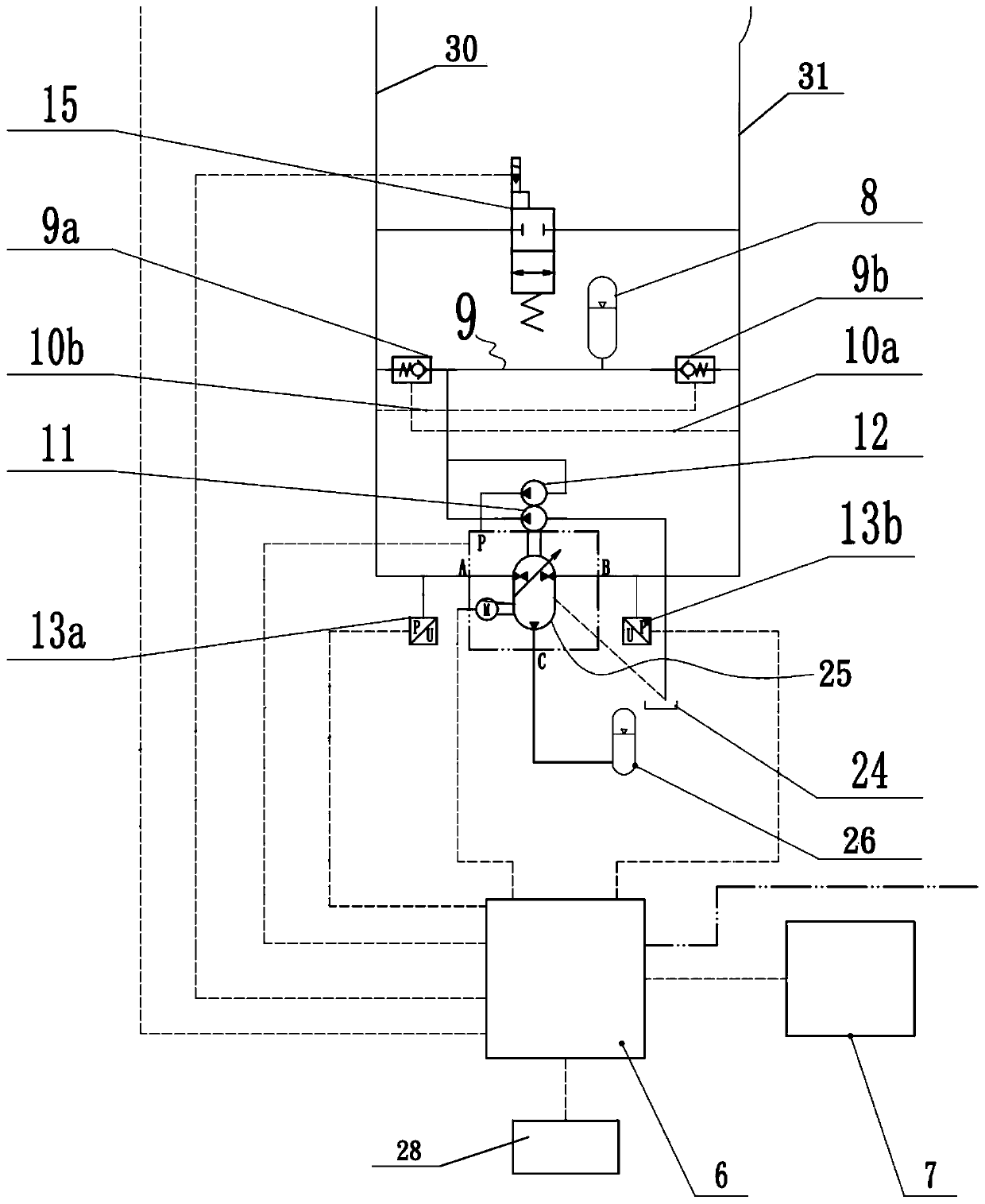

[0068] A pump-controlled semi-active heave compensation system, including a composite hydraulic cylinder 1, a hydraulic transformer 25 and a control unit, where the hydraulic transformer 25 is used in Embodiment 1 to replace the above-mentioned hydraulic power unit 3, wherein:

[0069] One way of the hydraulic transformer 25 is connected to the rod cavity C of the composite hydraulic cylinder 1 through the A port via the first oil passage 30, and the other is connected to the rodless chamber A of the composite hydraulic cylinder 1 through the B port via the second oil passage 31 cavity, the third road is connected with a low-pressure pump 11, the low-pressure pump 11 is connected with an oil tank 24, and the hydraulic transformer 25 is also connected with a hydraulic accumulator 26;

[0070] This hydraulic transformer 25 can be used as both a pump and a motor, allowing energy to be recovered and stored. By connecting the hydraulic transformer 25 in series with the hydraulic ac...

Embodiment 3

[0074] A pump-controlled semi-active heave compensation system, the structure of which is shown in Embodiment 1. The difference is that the working gas cylinders include 22 high-pressure working gas cylinders and 23 low-pressure working gas cylinders, 21 regulating gas cylinders, and 21 high-pressure working gas cylinders. 22 and the low-pressure working gas cylinder 23 are provided with on-off valves, and the on-off valves are connected to the second motor 29, and each second motor 29 is connected to the compensation controller 6 through the harness 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com