Down-the-hole holding-up hammer

A top hammer and down-the-hole technology, which is used in mining equipment and oil exploration fields, can solve the problems of reduced reliability, impact on performance and slag discharge effect, long exhaust gas path, etc., to ensure life and work reliability, Excellent slag discharge effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

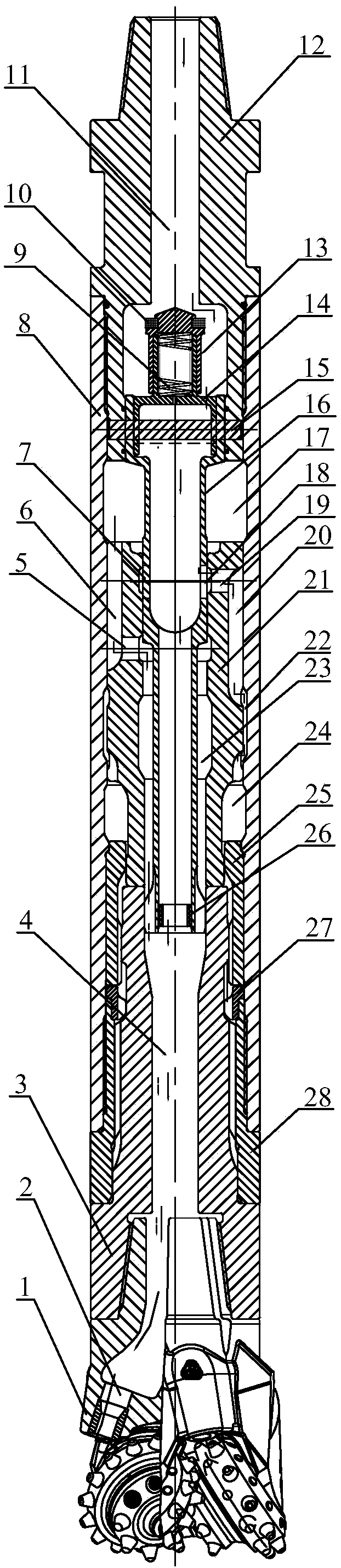

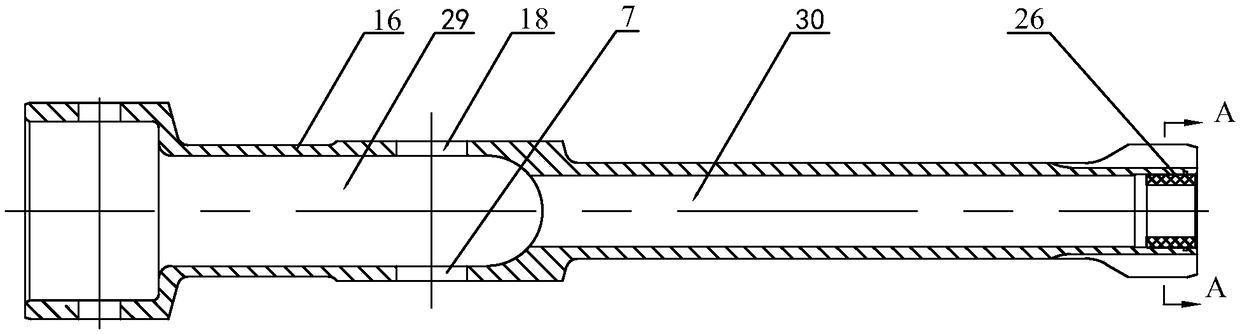

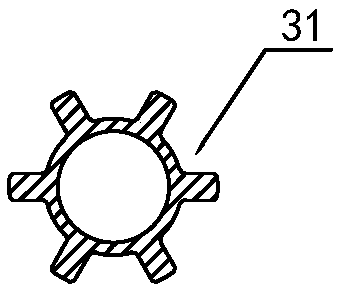

[0034] refer to Figure 1 to Figure 4 , a down-the-hole top hammer, comprising an outer casing 8, a check valve, a piston 21, a gas distribution rod 16, an impact joint 3, an upper joint 12, a lower joint 28, a guide sleeve 25, a retaining ring 27 and a roller cone bit 1; The upper and lower ends of the outer casing 8 are respectively fixedly socketed on the upper joint 12 and the lower joint 28, preferably, are respectively affixed to the upper and lower ends of the outer sleeve 8 through threaded upper and lower joints; the upper and lower joints are all hollow shape, wherein the central hole of the upper joint 12 is the air inlet; the roller cone bit 1 is installed on the lower joint 28 of the lower end of the outer sleeve 8 through the impact joint 3, and the roller cone bit 1 is fixedly connected with the impact joint 3 , preferably, the impact joint 3 with the API internal taper thread is fixedly connected with the drill pipe of the roller cone bit 1 with the API externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com