Combined type jet perforating device

A combined, jet technology, applied in the production of fluids, drilling with liquid/gas jets, wellbore/well components, etc., can solve the problems of jetting tool wear, jetting surface damage, etc. Efficiency, the effect of improving effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

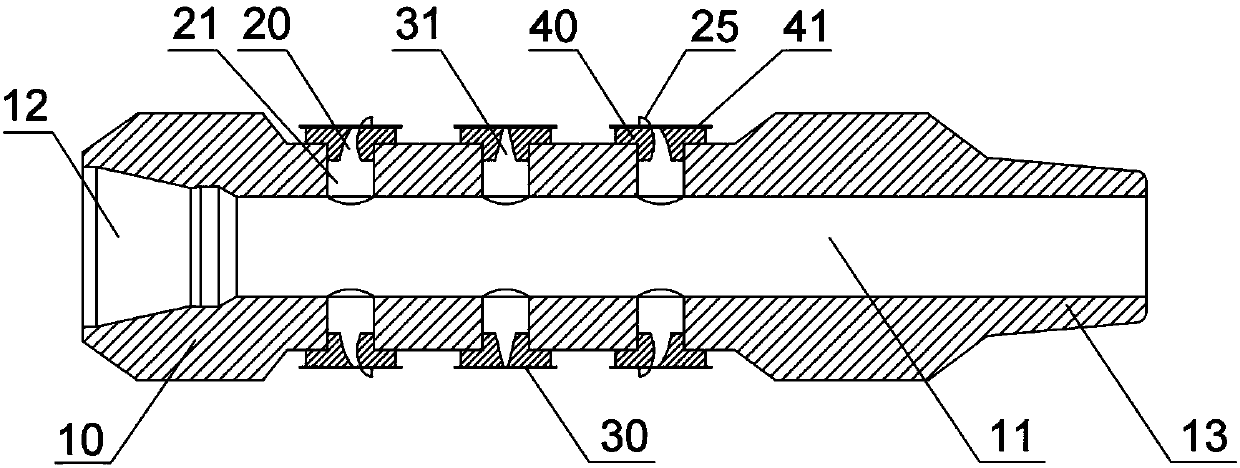

[0031] figure 1 A combined jet perforating device according to one embodiment of the present invention is schematically shown.

[0032] in such as figure 1 In the illustrated embodiment, the combined jet perforating device according to the invention comprises a body 10 . The body 10 is cylindrical, and the inner cavity is used for circulating high-pressure liquid. At least one straight jet nozzle 30 and at least two inclined jet nozzles 20 are arranged on the body 10 . Wherein, the jetting direction of the straight jet nozzle 30 is perpendicular to the central axis of the body 10 . The spraying direction of the inclined jet nozzle 20 is not perpendicular to the central axis of the body 10 and is biased toward the direction of the straight jet nozzle 30 . Two inclined jet nozzles 20 are arranged symmetrically on both sides of the direct-flow nozzle in the axial directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com