Corona-resistant polyimide based composite material and preparation method thereof

A polyimide-based, composite material technology, applied in the field of insulating materials, can solve the problems of reduced mechanical properties of composite materials, reduced uniformity of film corona resistance, and reduced corona resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The invention provides a method for preparing a corona-resistant polyimide-based composite material, comprising the following steps:

[0061] a) heating and reacting the anionic two-dimensional layered material and the organic intercalation agent in a first solvent to obtain an organic intercalation-modified layered material;

[0062] performing in-situ polymerization reaction of the layered material modified by organic intercalation and polyimide polymerized monomer in a second solvent to obtain mixed solution I;

[0063] b) performing in-situ polymerization reaction of inorganic nanoparticles and polymerized monomers of polyimide in a third solvent to obtain mixed solution II;

[0064] c) After mixing the mixed solution I and the mixed solution II, heat treatment is performed to obtain a polyimide-based composite material;

[0065] The anionic two-dimensional layered material is one or more of binary metal hydroxides and multi-element metal hydroxides;

[0066] The ...

Embodiment 1

[0152] Hydroxybutyric acid (2.29 g, 0.022 mol) and magnesium aluminum hydrotalcite (6.04 g, 0.01 mol) were added into ethylene glycol (100 mL), heated to 130° C., and reacted for 12 h. Afterwards, the solid matter was filtered out and dried to obtain hydrotalcite modified by hydroxybutyric acid intercalation with a yield of 98%. According to the wide-angle X-ray diffraction test, there is an obvious characteristic peak at 2θ=6.0°, and the interlayer distance is expanded to 1.47nm according to the Bragg equation.

[0153] Add the obtained hydroxybutyric acid-modified hydrotalcite (0.45g) and 4,4'-diphenyl ether diamine (2.00g, 10.0mmol) into N,N-dimethylacetamide (23g), stir at room temperature, Then, pyromellitic dianhydride (2.18 g, 10.0 mmol) was added and stirred at room temperature for 24 hours to obtain a mixed solution I. After testing, the bulk viscosity of the mixed solution I is 1.0dL / g, and the rotational viscosity is 16×10 5 cP.

[0154] Add nano-alumina (0.84g) ...

Embodiment 2

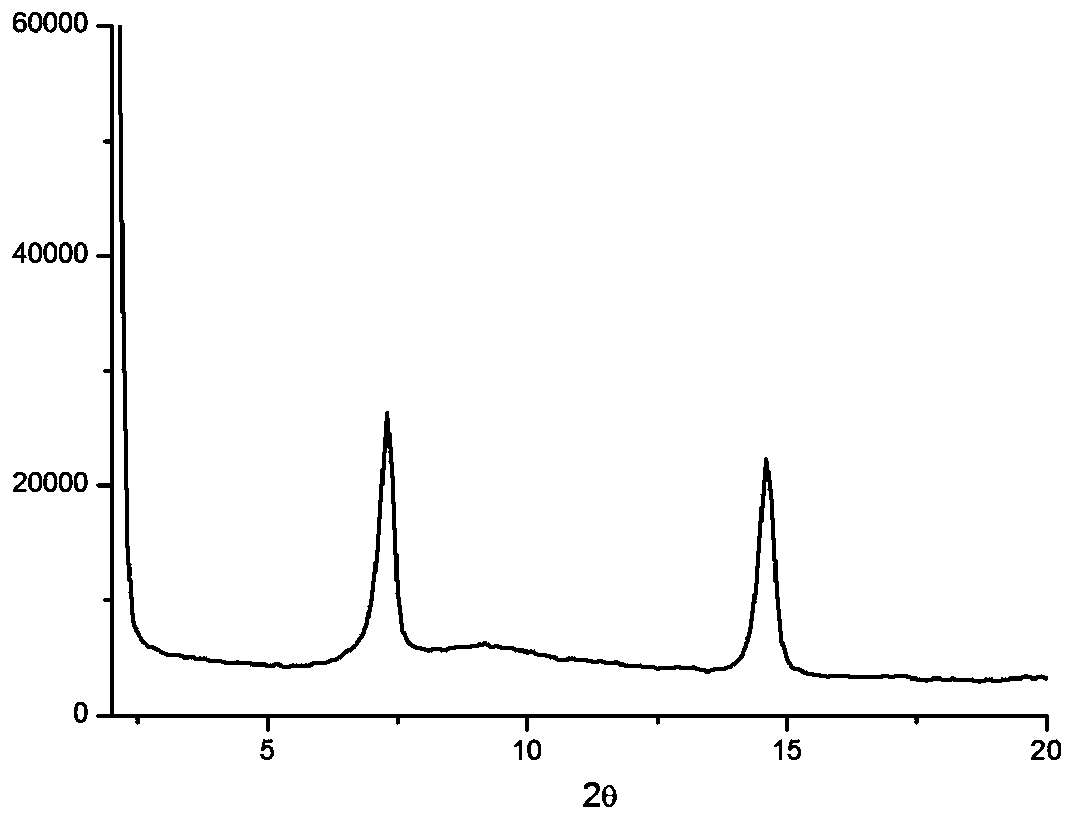

[0157] Add aminobutyric acid (2.26g, 0.022mol) and magnesium aluminum hydrotalcite (6.04g, 0.01mol) to ethylene glycol (100mL), heat to 130°C, and react for 12h. After that, the solid matter was filtered out and dried to obtain GABA-modified hydrotalcite with a yield of 94%. Gained sample is carried out wide-angle X-ray diffraction test, the result is as follows figure 1 as shown, figure 1 It is the X-ray diffraction pattern of the hydrotalcite modified by aminobutyric acid intercalation in Example 2. It can be seen that there is an obvious characteristic peak at 2θ=4.8°, and the interlayer distance is enlarged to 1.83nm calculated by combining the Bragg equation.

[0158] Add the obtained aminobutyric acid-modified hydrotalcite (0.50g) and 4,4'-diphenyl ether diamine (2.00g, 10.0mmol) into N,N-dimethylacetamide (23g), stir at room temperature, Then 4,4'-biphenyldianhydride (2.94g, 10.0mmol) was added and stirred at room temperature for 24 hours to obtain a mixed solution I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com