Chamfering grinding device used for motor stator and operation method of chamfering grinding device

A motor stator and chamfering technology, which is used in grinding/polishing equipment, machine tools suitable for grinding workpiece edges, metal processing equipment, etc. Small problems such as avoiding shaking, improving chamfering efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

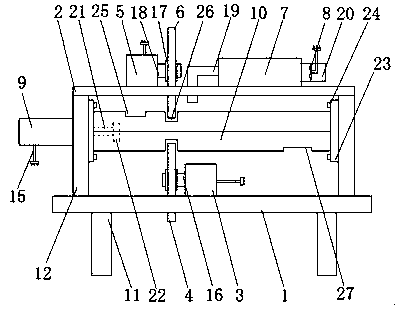

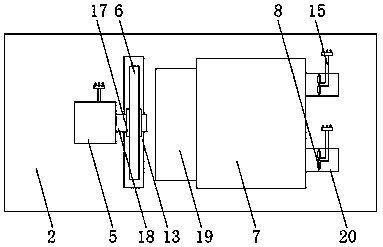

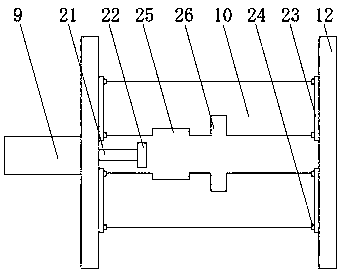

[0025] as attached Figure 1-4 As shown, a chamfering and grinding equipment for motor stators includes a bottom plate 1, a top plate 2, a motor one 3, a chamfering wheel one 4, a motor two 5, a chamfering wheel two 6, a chip collection box 7, a fan 8, The cylinder 9 and the limiting plate 10 are characterized in that: the base plate 1 is arranged on the support 11, the base plate 1 is provided with a vertical plate 12, a fixing groove 13, and a limiting groove 14 is arranged on the vertical plate 12, so The top plate 2 is set on the vertical plate 12, the motor one 3 is set on the bottom, and the motor one 3 is provided with a power line 15 and a transmission shaft one 16, and the bottom of the chamfering wheel one 4 passes through Fixing groove 13 on the bottom, and chamfering wheel one 4 is arranged on transmission shaft one 16 by mounting ring 17, described motor two 5 is arranged on the top plate 2, and is provided with power line 15, on motor two 5, Transmission shaft t...

Embodiment 2

[0037] as attached Figure 5 As shown, a chamfering and grinding equipment for motor stators includes a bottom plate 1, a top plate 2, a motor one 3, a chamfering wheel one 4, a motor two 5, a chamfering wheel two 6, a chip collection box 7, a fan 8, The cylinder 9 and the limiting plate 10 are characterized in that: the base plate 1 is arranged on the support 11, the base plate 1 is provided with a vertical plate 12, a fixing groove 13, and a limiting groove 14 is arranged on the vertical plate 12, so The top plate 2 is set on the vertical plate 12, the motor one 3 is set on the bottom, and the motor one 3 is provided with a power line 15 and a transmission shaft one 16, and the bottom of the chamfering wheel one 4 passes through Fixing groove 13 on the bottom, and chamfering wheel one 4 is arranged on transmission shaft one 16 by mounting ring 17, described motor two 5 is arranged on the top plate 2, and is provided with power line 15, on motor two 5, Transmission shaft two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com