A ceramic ferrule automatic production line

An automatic production line, ceramic ferrule technology, applied in glass production, grinding automatic control device, grinding drive device, etc., can solve the problem of inability to adapt to the change of size and specification of ceramic ferrule, so as to improve enterprise profitability and reduce costs , the effect of enhancing social benefits

Active Publication Date: 2022-05-31

NINGBO BRIGHT PHOTOELECTRIC TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Existing automation equipment or semi-automation equipment cannot adapt to ceramic ferrules with changing sizes and specifications. Therefore, the same style needs to design and manufacture structures with different sizes.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0037] It will be apparent to those skilled in the art that the invention is not limited to the details of the above-described exemplary embodiments, but also

[0038] Furthermore, it should be understood that although this specification is described in terms of embodiments, not every embodiment includes only

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

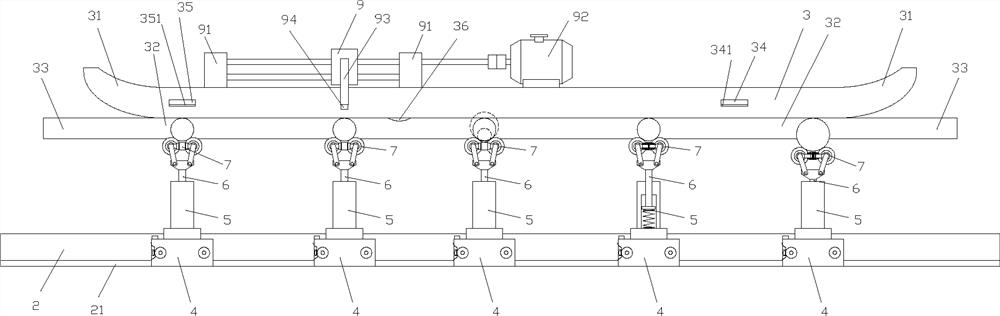

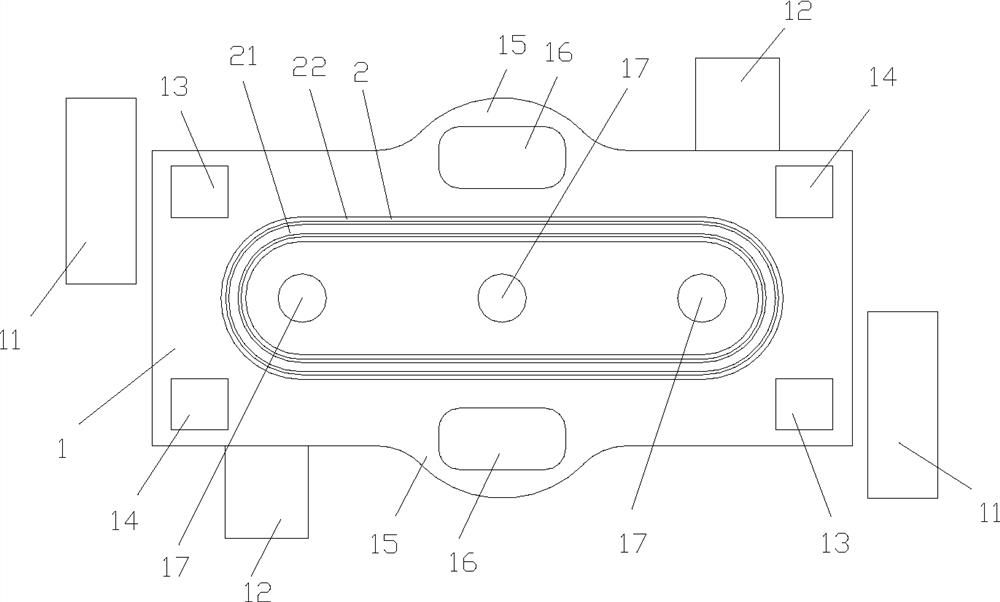

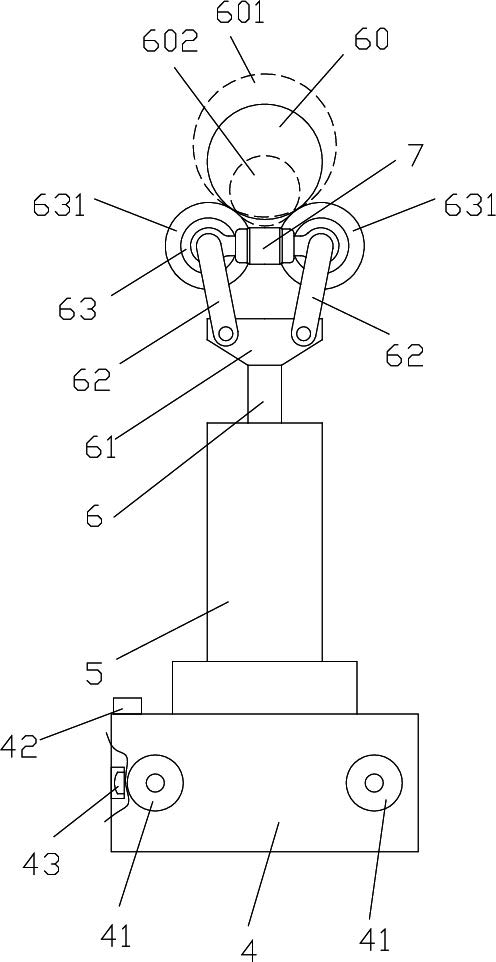

The invention discloses an automatic ceramic ferrule production line, which comprises a working platform, which is provided with a feeding conveying device and a discharging conveying device; the four corners of the working platform are provided with a feeding manipulator mounting seat and a material discharging manipulator mounting seat , there is a grinding part mounting seat in the middle of the two long sides of the working platform, a chamfering grinding mechanism is installed on the grinding part mounting seat, a racetrack-shaped track part is set on the working platform, and a Column, the top of the column is supported by an upper pressure plate, and several mobile bases are slidingly arranged on the track part. The mobile base drives the ceramic ferrule to move, and moves from the feeding manipulator mounting seat to the discharging manipulator mounting seat, and cooperates with the upper pressure plate to make the ceramic ferrule The core rotates, and finally it is chamfered by a chamfering grinding mechanism. The invention is suitable for ceramic ferrules of different diameters and can efficiently and stably process the chamfering of the ceramic ferrule.

Description

A ceramic ferrule automatic production line technical field [0001] The present invention relates to a ceramic ferrule automated production line. Background technique [0002] The ceramic ferrule is the core component of the optical fiber connector, and the ceramic ferrule is characterized by a smooth outer circle, light weight, and big. After the ceramic ferrule is processed, it needs to be pressed into the metal tailstock to facilitate the assembly and use of downstream customers. The process has good guidance and prevents the sharp edge of the ferrule from scooping up metal chips and blocking the inner hole. It needs to be added at the tail of the ceramic ferrule. Work chamfering. One type of existing chamfering equipment is semi-automatic equipment, and the loading, clamping and unloading of ceramic ferrules all require manual operation. Although the other type of processing equipment adopts automation, the equipment structure is complex and the cost is high. An...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24B9/06B24B27/00B24B41/00B24B41/06B24B47/00B24B47/12B24B47/20B24B49/12B24B51/00

CPCB24B9/06B24B41/067B24B27/0069B24B41/005B24B47/20B24B49/12B24B47/00B24B47/12B24B51/00Y02P40/57

Inventor 曹波

Owner NINGBO BRIGHT PHOTOELECTRIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com