Core rod cooling process method and core rod cooling device

A cooling process and mandrel technology, used in manufacturing tools, metal processing equipment, metal rolling, etc., can solve the problem of uneven wall thickness of steel pipes, achieve accurate cooling effect, ensure uniformity, and meet the effect of cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The cooling process method of the mandrel described in the present embodiment, the steps are as follows:

[0065] (1) After the mandrel is dephosphorized, the mandrel is in the hollow box 1, passes through the ring center of the cooling ring 2, and advances along the axial direction of the mandrel at a speed of 1-2m / s, passing through the first temperature The detector 7 measures the temperature T of each place of the mandrel, and the temperature detector feeds back the measured temperature T of the mandrel to the PLC module, and the PLC module compares the temperature T with the preset temperature T 0 For comparison, the PLC module controls the opening and closing of the nozzles on the cooling rings in real time according to the comparison results, and adjusts the amount of air mist cooled by the mandrel along the axial direction according to the temperature T. The higher the temperature, the greater the amount of air mist , the lower the temperature, the smaller the a...

Embodiment 2

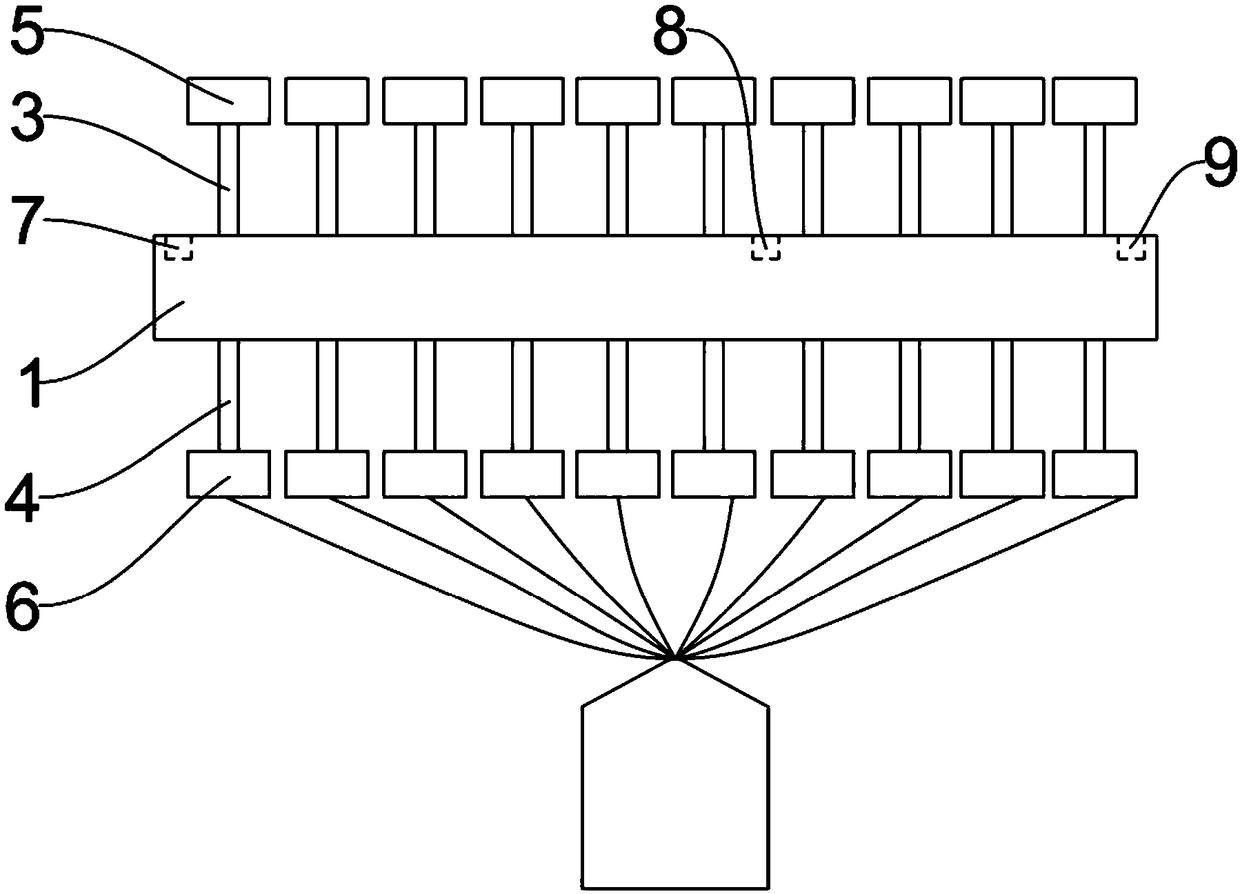

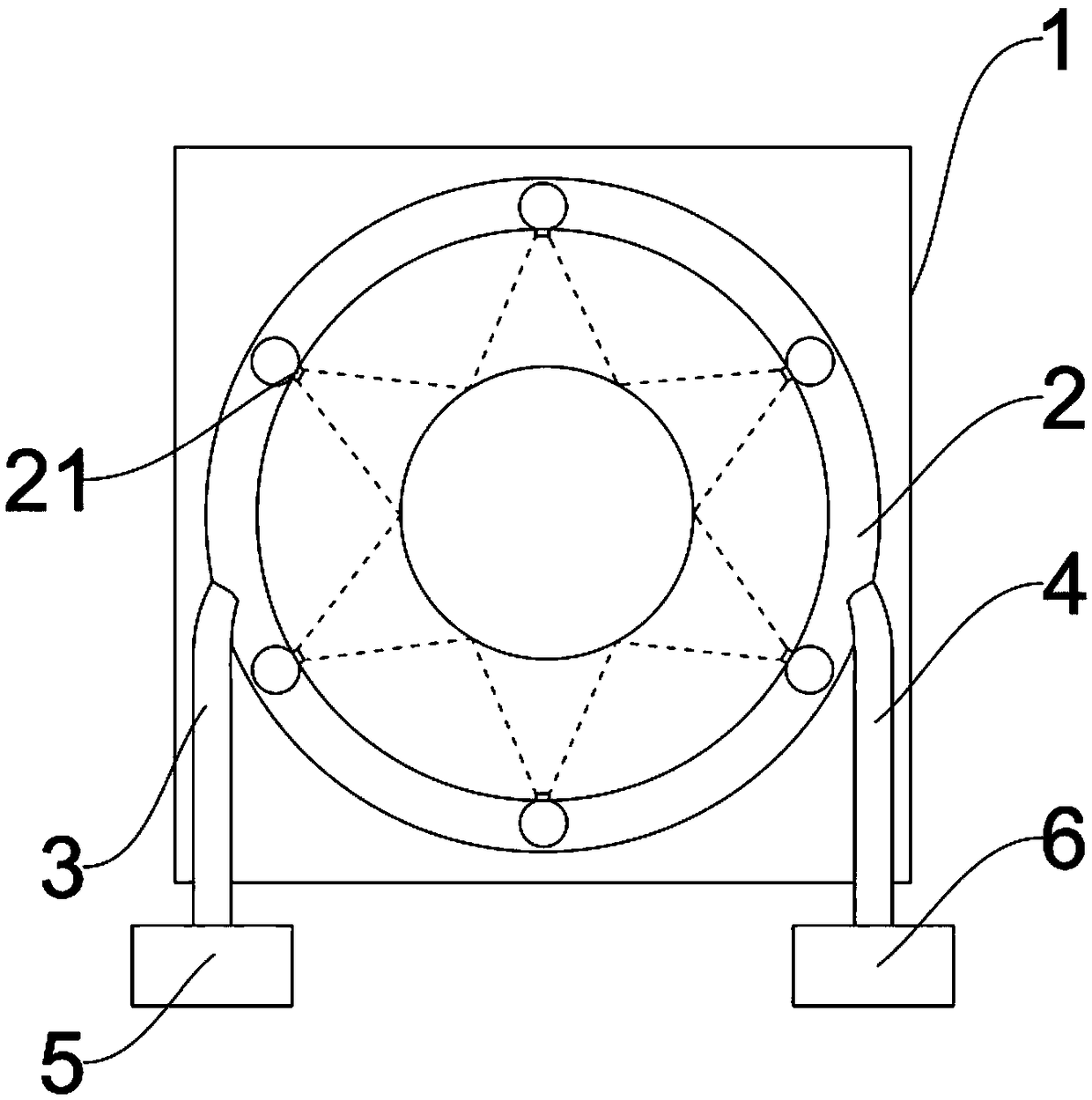

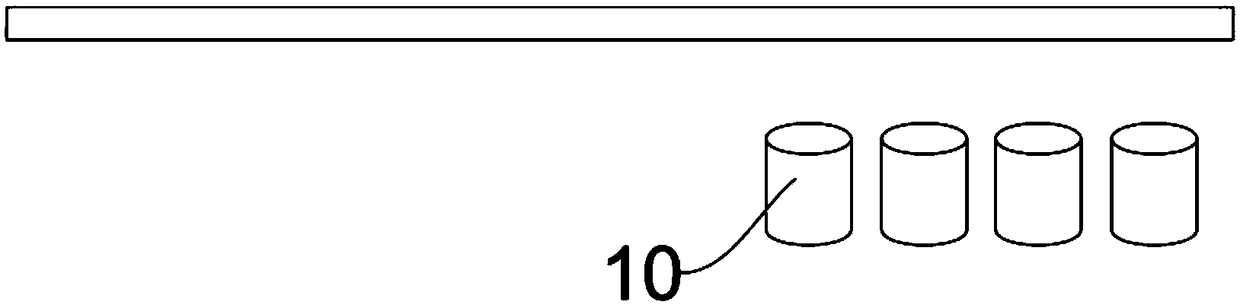

[0069] In this embodiment, the device with 10 cooling rings 2 arranged in parallel is taken as an example. The first temperature detector 7 is arranged before the first cooling ring, and the second temperature detector 8 is arranged at the sixth and seventh cooling rings. Between the rings, the third temperature detector 9 is arranged behind the tenth cooling ring. Six nozzles 21 are evenly arranged on the inner side of the cooling ring 2 along the circumferential direction of the cooling ring. The spray angle of the nozzles 21 is 30°, so The distance between the nozzle 21 and the mandrel is 105mm. Taking the use of a mandrel with a length of 10m as an example, the steps of the cooling process for the mandrel are as follows:

[0070](1) After the mandrel is dephosphorized, the mandrel is in the hollow box 1, passes through the center of the cooling ring 2, advances along the axial direction of the mandrel at a speed of 1.5m / s, and passes through the first temperature detection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com