A process method and device for mandrel soaking

A process method and mandrel technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal rolling, etc., can solve the problems of uneven wall thickness of steel pipes, achieve the effects of protecting the environment, improving uneven wear of mandrel rods, and facilitating temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

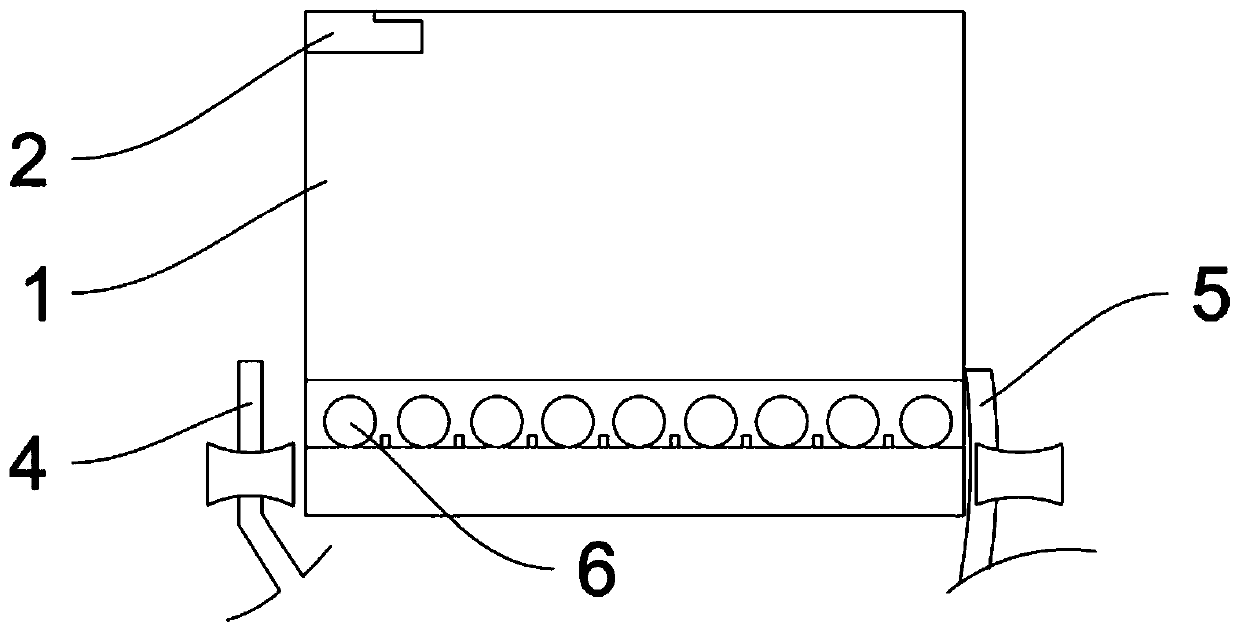

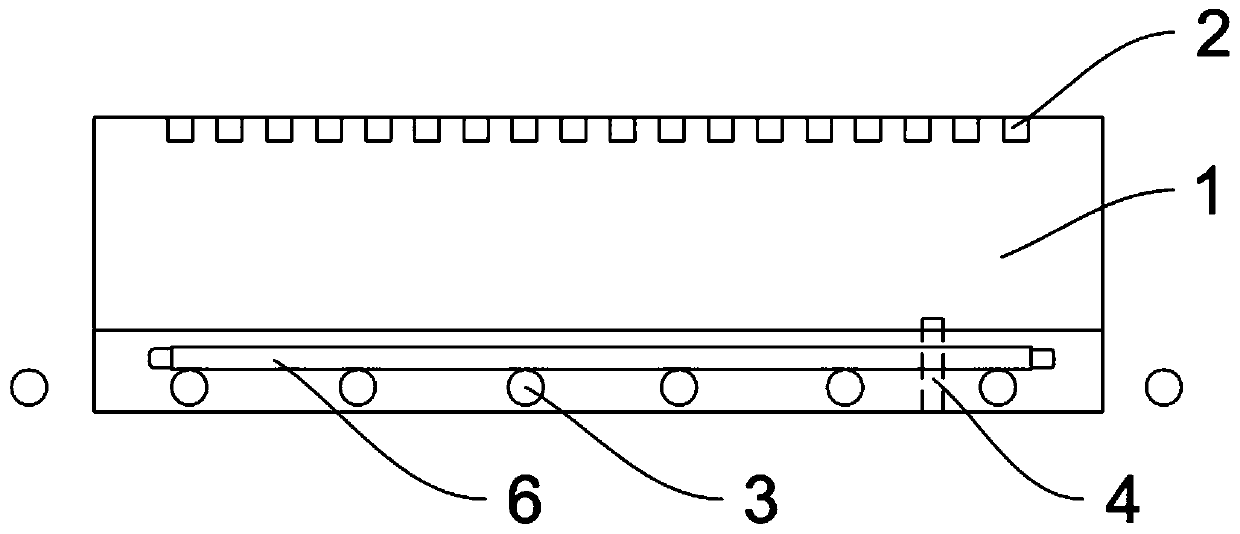

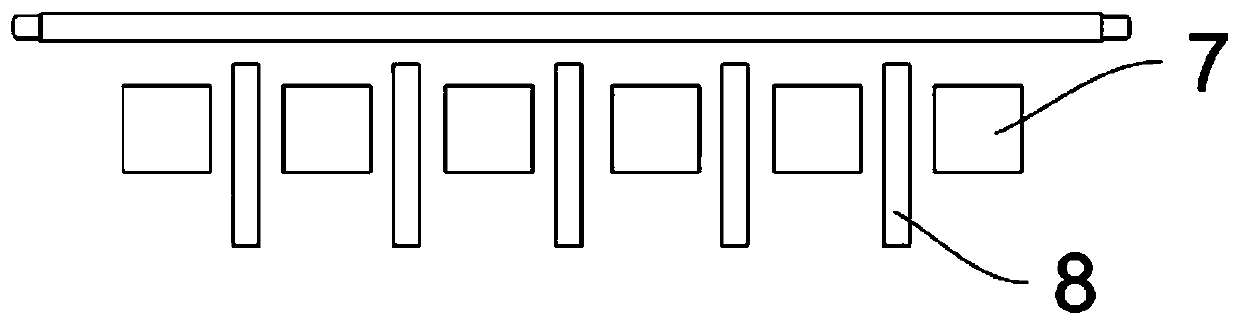

[0067] The process method of the mandrel soaking heat described in the present embodiment, the steps are as follows:

[0068] (1) Transfer the mandrel obtained after the last rolling and stripping to the front roller table of the drive roller 3, and send the mandrel into the soaking device through the material hook 4; the average of the mandrel The temperature T is 500°C, the use length of the mandrel is 10m, and the temperatures of the mandrel from the head to the tail of the use length are 0-3m, 560-520°C; 3-6m, 520-500°C; 6 -7m, 500-480°C; 7-10m, 480-410°C;

[0069] (2) Open the burner with a length of 7m-10m corresponding to the mandrel, and adjust the opening size of the burner at 9m-10m to 15%, and the opening size of the burner at 7m-8m to 12%; the burner is through natural gas Combustion ejects a flame with a temperature of 1300-1400°C;

[0070] (3) Adjust the ambient temperature in the furnace body 1 to 400°C, correspondingly use a mandrel with a length of 0m-5m to ...

Embodiment 2

[0074] The process method of the mandrel soaking heat described in the present embodiment, the steps are as follows:

[0075] (1) Transfer the mandrel obtained after the last rolling and stripping to the front roller table of the drive roller 3, and send the mandrel into the soaking device through the material hook 4; the average of the mandrel The temperature T is 450°C, the use length of the mandrel is 15m, and the temperatures of the mandrel from the head to the tail of the use length are 0-3m, 520-500°C; 3-6m, 500-480°C; 6 -7m, 480-460°C; 7-8m, 460-440°C, 8-10m, 440-430°C; 10-12m, 430-405°C; 12-15m, 405-380°C;

[0076] (2) Open the burner with a length of 8m-15m corresponding to the mandrel, and adjust the opening size of the burner at 12m-15m to 16%, and the opening size of the burner at 8m-11m to 13%; the burner is through natural gas Combustion ejects a flame with a temperature of 1300-1400°C;

[0077] (3) Adjust the ambient temperature in the furnace body 1 to 450°C,...

Embodiment 3

[0081] The process method of the mandrel soaking heat described in the present embodiment, the steps are as follows:

[0082] (1) Transfer the mandrel obtained after the last rolling and stripping to the front roller table of the drive roller 3, and send the mandrel into the soaking device through the material hook 4; the average of the mandrel The temperature T is 550°C, the use length of the mandrel is 8m, and the temperatures of the mandrel from the head to the tail of the use length are 0-2m, 600-585°C; 2-4m, 585-560°C; 4 -6m, 560-530°C; 6-8m, 530-510°C);

[0083] (2) Open the burner with a length of 6m-8m corresponding to the mandrel, and adjust the opening size of the burner at 7-8m to 13%, and the opening size of the 6m burner to 10%; A flame with a temperature of 1300-1400°C;

[0084] (3) Adjust the ambient temperature in the furnace body 1 to 350°C, corresponding to the use of mandrels with a length of 0m-5m for heat exchange with the environment of the furnace body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com