Temperature uniform pot with heating coil panel

A technology for heating coils and outer pots, which is applied to utensils with integral electric heating devices, household utensils, kitchen utensils, etc., can solve the problems of non-stick coating safety hazards, sticking to pots, and uncoated pots sticking to pans, etc. Achieve the effect of maintaining temperature uniformity, accelerating conduction, and small temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

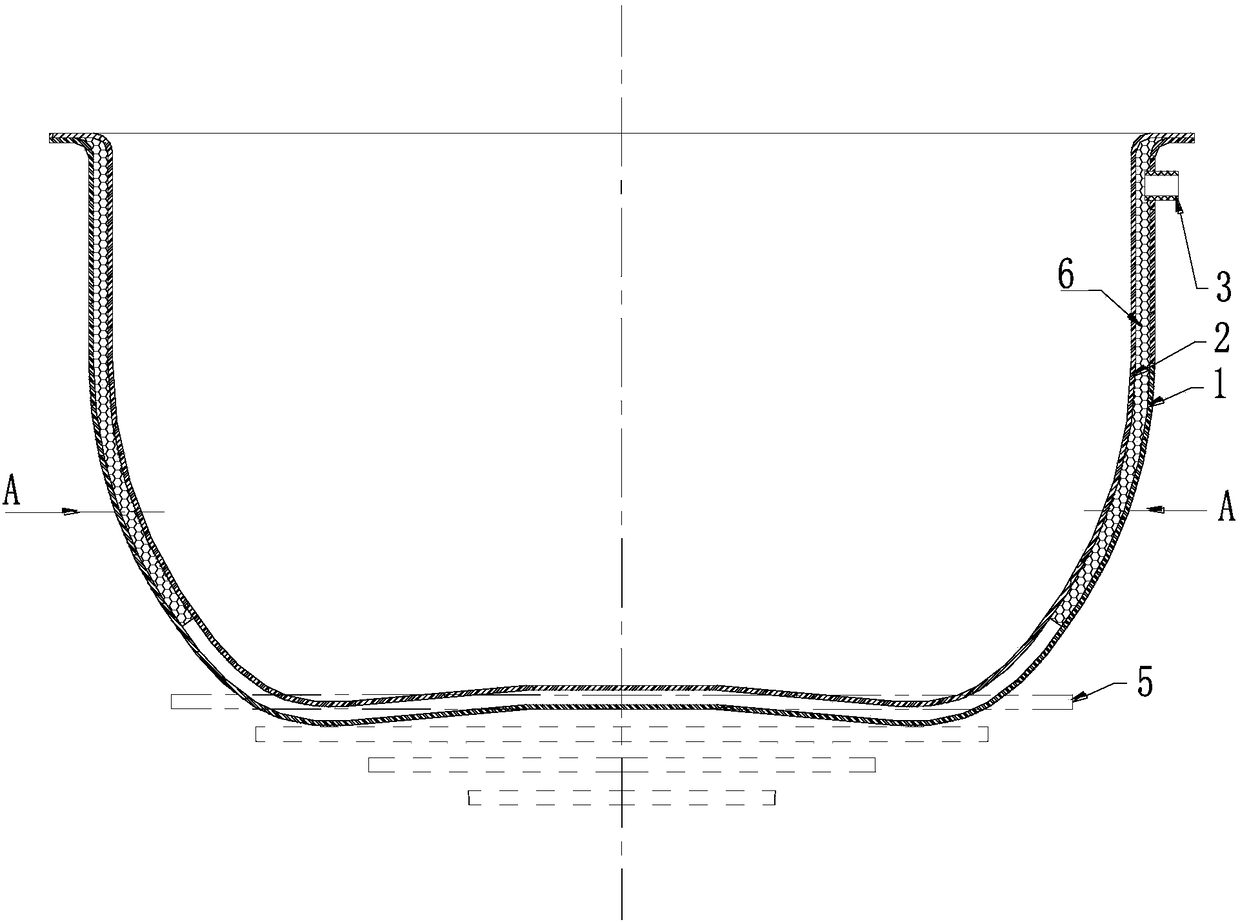

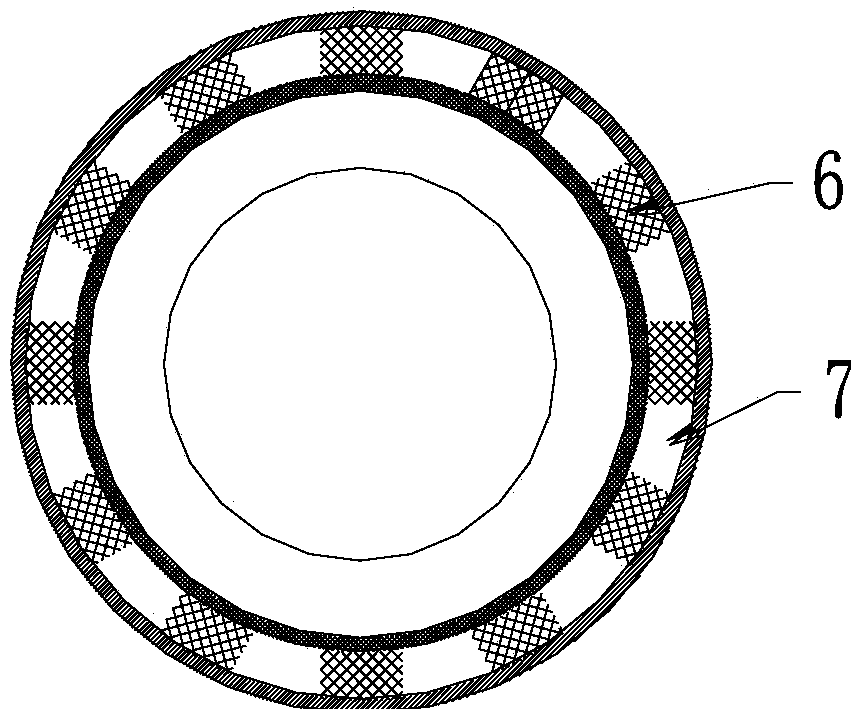

[0026] Such as figure 1 As shown, according to an embodiment of the present invention, a uniform temperature pot with a heating coil plate includes an inner pot 1 and an outer pot 2 with the same shape and different volumes, the inner pot 1 is set inside the outer pot 2, and the The top of the inner pot 1 is sealed and fixedly connected with the top of the outer pot 2, and a vacuum chamber 7 is formed between the inner pot 1 and the outer pot 2; liquid phase change working medium; the vacuum chamber 7 is provided with a liquid-absorbing core 4; the heating coil disk 5 is located on the outer surface of the outer pot 2, and the lowest end of the liquid-absorbing core 4 is higher than the heating coil disk 5 for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com