Pipeline sewage discharging robot

A robot and pipeline technology, applied in the field of robots, can solve the problems of energy waste, reduce heat exchange efficiency, blockage of conveying pipelines, etc., and achieve the effect of improving sewage efficiency and preventing energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

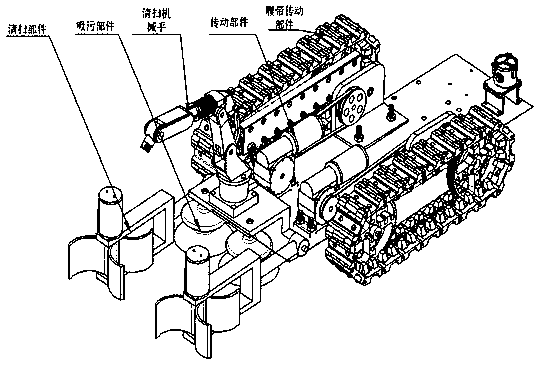

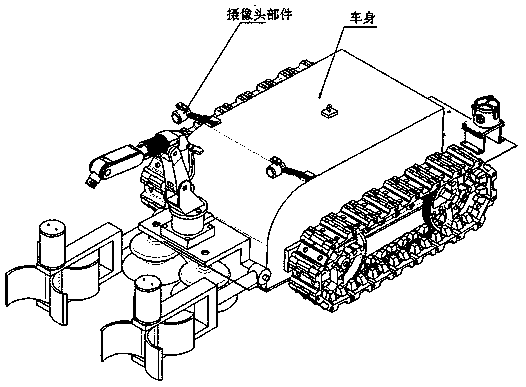

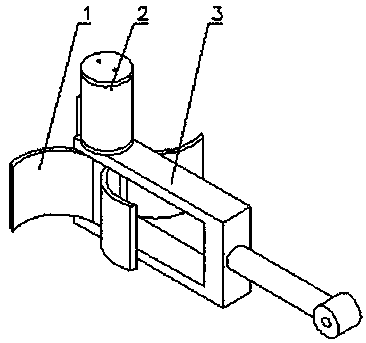

[0044] Embodiment 1: as Figure 1~9 As shown, an automatic sewage robot includes two cleaning components, two sewage suction components, a cleaning manipulator, two transmission components, two crawler transmission components, two camera components, and a vehicle body;

[0045] Described vehicle body comprises base plate 28, cover plate 29 and installation platform 30, and described cover plate 29 is fixed on the top of base plate 28, and described installation platform 30 is fixed on described cover plate 29 front ends, and described two cleaning components are connected with the vehicle body respectively. The two ends of the mounting table 30 are connected, and the two suction parts are located under the mounting table 30 of the vehicle body, and the tops of the two suction parts are respectively installed on the mounting table 30 at the front end of the vehicle body. Dirty components are all located inside the two cleaning components, the cleaning manipulator is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com