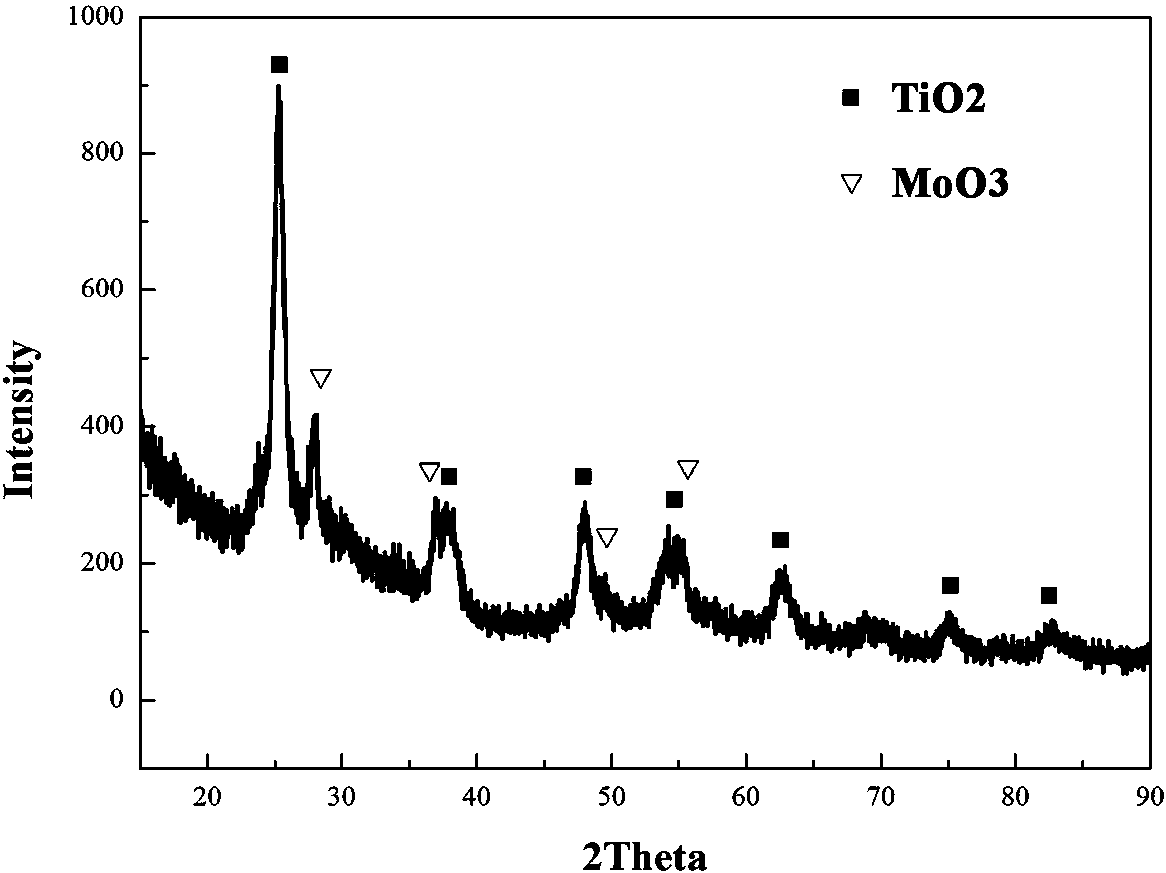

Method for preparing molybdenum trioxide doped titanium dioxide nano catalyst

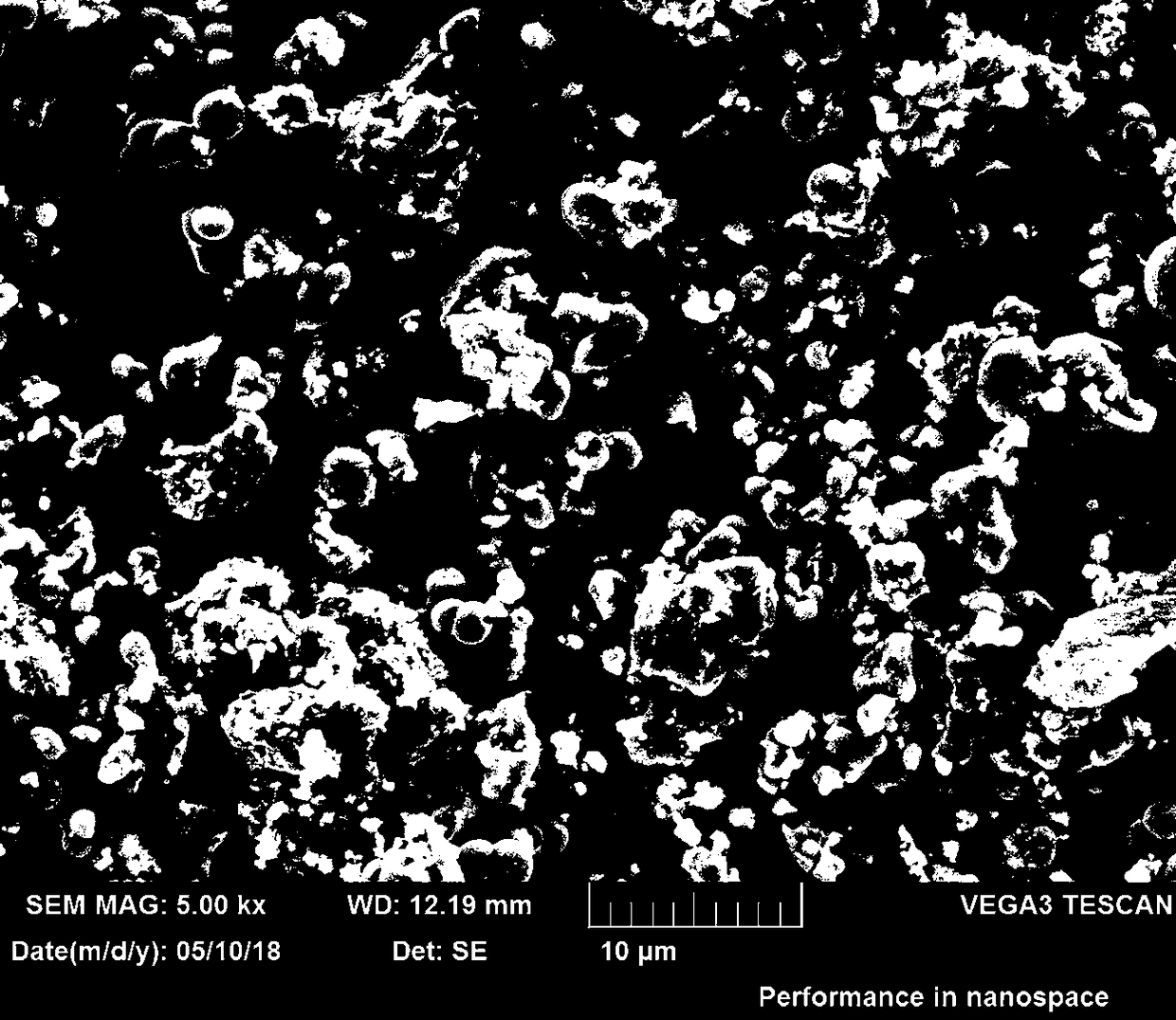

A nano-photocatalyst, titanium dioxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of uncontrollable particle size of catalyst powder, same material particles Easy to agglomerate, poor compatibility of the two materials, etc., to achieve the effect of excellent synergistic photocatalytic performance, good dispersibility, and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of MoO 3 doped TiO 2 The preparation method of nanometer photocatalyst powder, comprises the following steps:

[0034] Step 1. After mixing concentrated nitric acid and distilled water, prepare a dilute nitric acid solution with a concentration of 2-14mol / L, fully stir and mix, and set aside;

[0035] The concentration of dilute nitric acid is shown here, because if its concentration is too high, the reaction of tetrabutyl titanate added later will be insufficient, otherwise, the reaction of ammonium tetramolybdate will be insufficient.

[0036] Step 2. Add tetrabutyl titanate drop by drop to the dilute nitric acid solution prepared in step 1, and stir while adding dropwise. The stirring rate is 600~1200r / min to obtain solution A. Tetrabutyl titanate in solution A The final concentration of ester is 0.02 ~0.2mol / L;

[0037] In this step, the addition of tetrabutyl titanate needs to be carried out under stirring conditions, because tetrabutyl titanate and water...

Embodiment 1

[0049] A kind of MoO 3 doped TiO 2 The preparation method of nanometer photocatalyst powder, comprises the following steps:

[0050] Step 1, after mixing concentrated nitric acid and distilled water, prepare 500ml of dilute nitric acid solution with a concentration of 2mol / L, fully stir and mix, and set aside;

[0051] Step 2: Take 34g (that is, 0.1mol) tetrabutyl titanate, and at a stirring rate of 1000r / min, add tetrabutyl titanate drop by drop to the prepared product in step 1 by adding it dropwise while stirring. In dilute nitric acid solution, make solution A, standby;

[0052] Step 3: Take 92.4g of ammonium tetramolybdate and add it to the solution A prepared in step 2, and stir to make it completely mixed to obtain solution B for subsequent use;

[0053] Step 4. Transfer the solution B prepared in step 3 to the polytetrafluoroethylene lining of the stainless steel hydrothermal kettle, and then put it into a drying oven for hydrothermal reaction. Control the drying ov...

Embodiment 2

[0059] A kind of MoO 3 doped TiO 2 The preparation method of nanometer photocatalyst powder, comprises the following steps:

[0060] Step 1. After mixing concentrated nitric acid with distilled water, prepare 500ml of dilute nitric acid solution with a concentration of 4mol / L, fully stir and mix, and set aside;

[0061] Step 2: Take 3.4g (that is, 0.01mol) of tetrabutyl titanate, and at a stirring rate of 600r / min, add tetrabutyl titanate drop by drop to step 1 to prepare In the dilute nitric acid solution, make solution A, standby;

[0062] Step 3: Take 5.6g of ammonium tetramolybdate and add it into solution A prepared in step 2, stir to make it completely mixed, and then obtain solution B, which is set aside;

[0063] Step 4. Transfer the solution B prepared in step 3 to the polytetrafluoroethylene lining of the stainless steel hydrothermal kettle, and then put it into a drying oven for hydrothermal reaction. Control the drying oven to heat up to 200℃, hydrothermal reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com