Nitrogen oxide flue gas absorption and acid production system

A nitrogen oxide and flue gas technology, which is applied in the field of nitrogen oxide flue gas absorption and acid production system, can solve the problems of exhaust gas emission that is difficult to meet the standard, and there is no treatment process, so as to improve resource utilization, system structure design is reasonable, flue gas good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

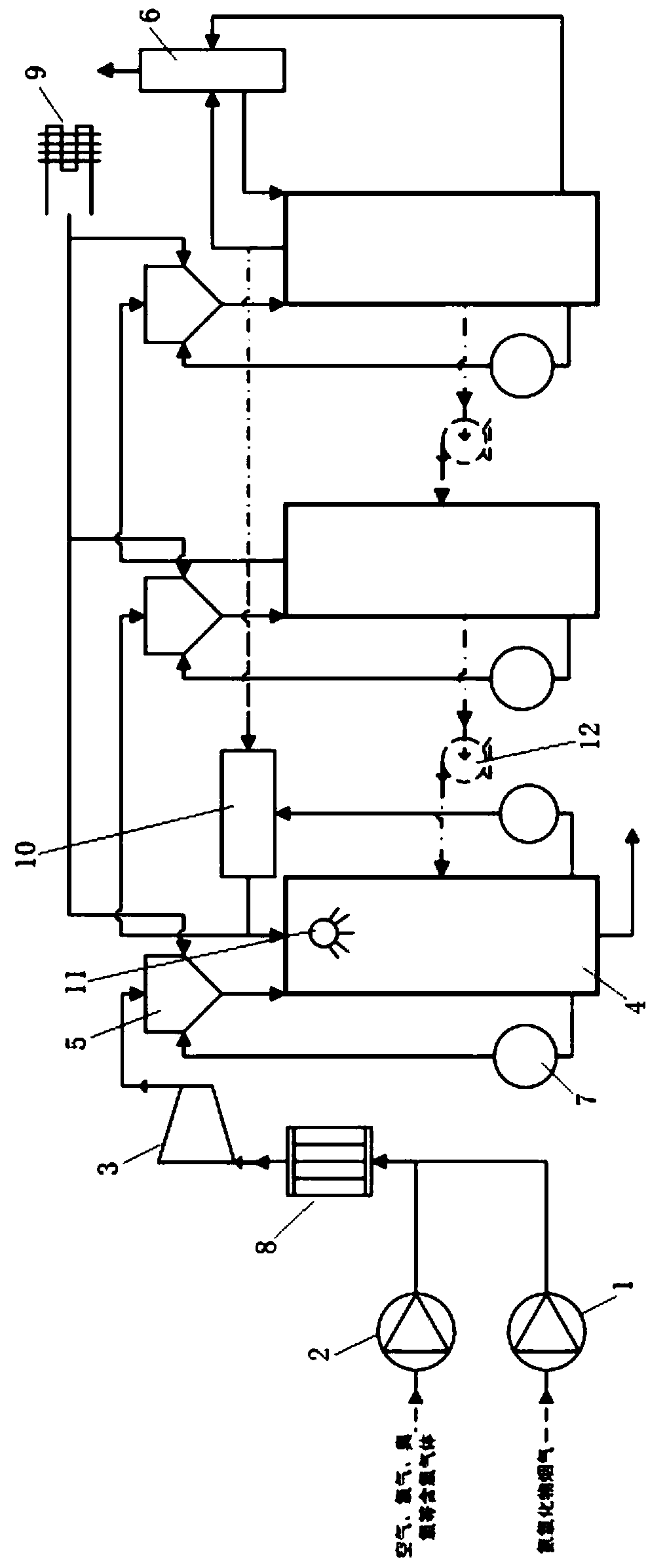

[0032] Embodiment: As shown in the figure, the nitrogen oxide flue gas absorption system for acid production in this embodiment includes a flue gas delivery device 1, an oxygen-containing gas delivery device 2, multiple acid tanks 4, and multiple absorbers 5 and exhaust gas purifier 6;

[0033] A plurality of above-mentioned acid-making tanks 4 are arranged sequentially in sequence, and the upper end of each of the above-mentioned acid-making tanks 4 is provided with a liquid inlet and a first overflow port communicating with its interior;

[0034] A plurality of the above-mentioned absorbers 5 correspond to a plurality of the above-mentioned acid-making tanks 4 one by one, and the liquid outlet of each of the above-mentioned absorbers 5 is communicated with the liquid inlet of the corresponding above-mentioned acid-making tanks 4 through pipelines;

[0035] The output ends of the above-mentioned flue gas conveying device 1 and the oxygen-containing gas distribution conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com