A kind of production method of freeze-dried instant egg powder

A production method and technology of egg powder, which is applied in the field of egg powder production, can solve problems such as easy residual air bubbles, low air bubble rate, and reduced moisture gasification efficiency, so as to ensure preservation and solve the effects of slow drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

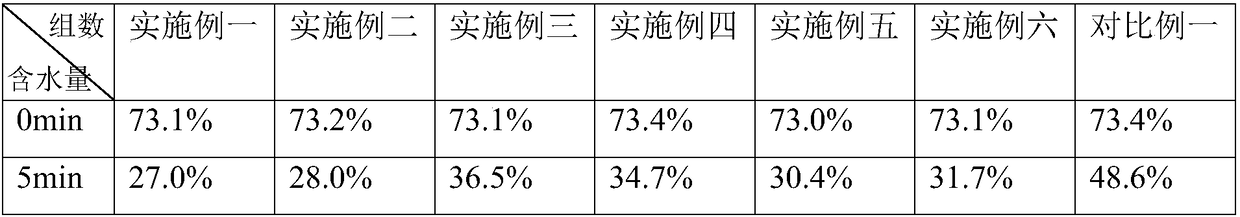

Examples

Embodiment 1

[0027] A production method of freeze-dried instant egg powder, comprising the steps of:

[0028] (1) cleaning, cleaning the eggshell surface of the raw egg until there is no impurity;

[0029] (2) beat the eggs and stir, put the washed eggs into the container, and beat them with a mixer until the egg yolks break;

[0030] (3) Estering and homogenization, adding 0.5% lard of egg liquid mass percentage to the egg liquid obtained in the above steps, stirring for three minutes by a stirrer until uniform;

[0031] (4) Arrange the plate, pour the egg liquid into the steaming plate, and put it into the steaming cabinet;

[0032] (5) Steaming, set the temperature of the steaming cabinet to 85°C, heat through steam, and continue steaming for 7 minutes after reaching the target temperature;

[0033] (6) Cool and turn over the plate, let the steamed eggs cool until solidified, cut into small cubes and pour them into the quick-freezing plate;

[0034] (7) Quick-freezing, the temperatur...

Embodiment 2

[0039] A production method of freeze-dried instant egg powder, comprising the steps of:

[0040] (1) cleaning, cleaning the eggshell surface of the raw egg until there is no impurity;

[0041] (2) beat the eggs and stir, put the washed eggs into the container, and beat them with a mixer until the egg yolks break;

[0042] (3) Estering and homogenizing, adding 0.5% butter of the egg liquid mass percentage to the egg liquid obtained in the above steps, and stirring for three minutes with a stirrer until evenly stirred;

[0043] (4) Arrange the plate, pour the egg liquid into the steaming plate, and put it into the steaming cabinet;

[0044] (5) Steaming, set the temperature of the steaming cabinet to 85°C, heat through steam, and continue steaming for 7 minutes after reaching the target temperature;

[0045] (6) Cool and turn over the plate, let the steamed eggs cool until solidified, cut into small cubes and pour them into the quick-freezing plate;

[0046] (7) Quick-freezin...

Embodiment 3

[0051] A production method of freeze-dried instant egg powder, comprising the steps of:

[0052] (1) cleaning, cleaning the eggshell surface of the raw egg until there is no impurity;

[0053] (2) beat the eggs and stir, put the washed eggs into the container, and beat them with a mixer until the egg yolks break;

[0054] (3) Estering and homogenization, adding soybean oil with 0.5% mass percentage of egg liquid to the egg liquid obtained in the above steps, stirring for three minutes by a stirrer until uniform;

[0055] (4) Arrange the plate, pour the egg liquid into the steaming plate, and put it into the steaming cabinet;

[0056] (5) Steaming, set the temperature of the steaming cabinet to 85°C, heat through steam, and continue steaming for 7 minutes after reaching the target temperature;

[0057] (6) Cool and turn over the plate, let the steamed eggs cool until solidified, cut into small cubes and pour them into the quick-freezing plate;

[0058] (7) Quick-freezing, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com