Optical filter structure, preparation method thereof and method for adjusting transmission characteristics thereof

An optical filter and characteristic technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as limited application, and achieve the effects of short response time, simple and convenient preparation and adjustment methods, and simple and convenient preparation and use methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Such as figure 1 As shown, it is an optical filter structure of this embodiment, which is composed of a base layer 1, a control layer 2 and a dielectric layer 3 sequentially connected from bottom to top. The dielectric layer 3 is embedded with two rectangular metal nanoblocks 4, and the metal nano The upper surface of the block 4 is equal to the upper surface of the dielectric layer 3, the lower surface of the metal nano block 4 is higher than the lower surface of the dielectric layer 3, and the control layer 2 is VO 2 Thin films, metal nanoblocks 4 are made of noble metal materials.

[0033] Specifically: the metal nano-block 4 is made of a noble metal material, which can be one of gold and silver, and is preferably gold in this embodiment. The base layer 1 is a glass substrate, and the dielectric layer 3 is made of a transparent insulating material, preferably PMMA in this embodiment. The thickness of the dielectric layer 3 is 40-100 nm.

[0034] Specifically: in t...

Embodiment 2

[0038] Based on the optical filter structure disclosed in Embodiment 1, this embodiment discloses an optical filter by adjusting the length of the two rectangular metal nano-blocks 4 and the boundary between the two rectangular metal nano-blocks 4 and the dielectric layer 3 in this embodiment. The distance between them, their transmission characteristics and the change of the electric field.

[0039] Such as figure 1 As shown, when the two rectangular metal nano-blocks 4 are both 50nm long, the distance between the two rectangular metal nano-blocks 4 is 50nm, and the distance between the two rectangular metal nano-blocks 4 and the boundary of the dielectric layer 3 is 50nm, that is, the dielectric layer 3 The length is 250nm.

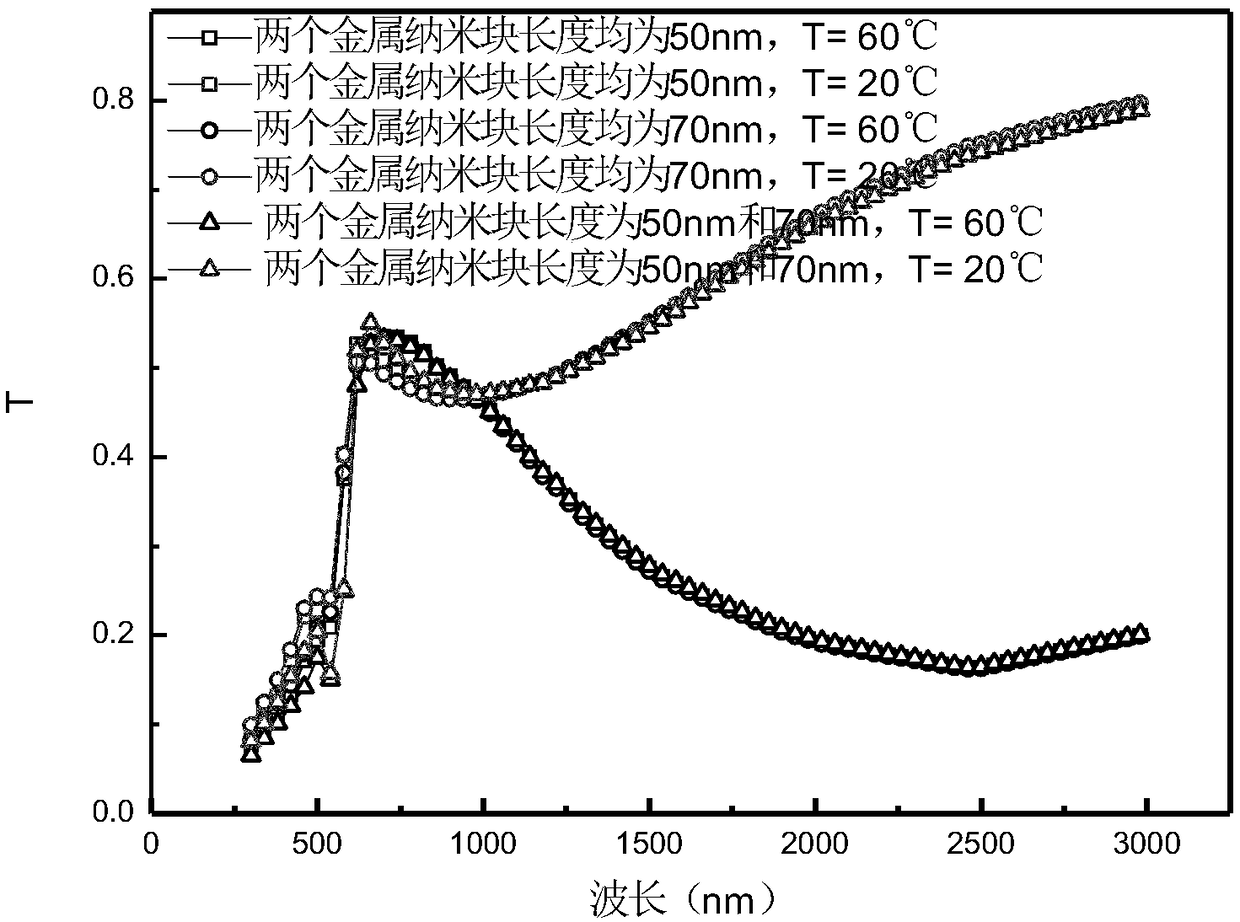

[0040] Such as figure 2 For the two transmission spectrum curves of the optical filter structure whose length of the dielectric layer 3 is 250nm, it is figure 2The transmission spectrum of the optical filter structure shown in the figure can be see...

Embodiment 3

[0043] Based on the optical filter disclosed in Embodiment 2, this embodiment discloses an optical filter. The difference from Embodiment 2 is that in this embodiment, such as figure 1 As shown, the length of the two rectangular metal nano-blocks 4 is 50nm, the distance between the two rectangular metal nano-blocks 4 is 50nm, and the distance between the two rectangular metal nano-blocks 4 and the boundary of the dielectric layer 3 is 75nm, that is, the distance of the dielectric layer 3 The length is 300nm.

[0044] In this embodiment, VO 2 The phase transition can be achieved by changing the temperature, so that VO 2 The lattice structure can be changed from tetragonal rutile structure (T>60°C) to monoclinic structure (T<60°C) or vice versa, so as to realize the change of regulated optical properties.

[0045] from figure 2 It can be seen in the figure that the filtering effect of the optical filter whose length of the dielectric layer 3 is changed to 300nm is the same a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com