Scratch-resistant diffusion film, backlight module set and liquid crystal display

A technology of backlight module and diffusion film, which is applied in the field of diffusion film, can solve the problem that the optical diffusion film is difficult to take into account the scratch resistance of other contact components, and achieve the effect of not easy to expand and deform, high sphericity, and good solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation process of the back coating of the anti-scratch diffusion film is as follows: After the semi-finished product of the diffusion film has been unwound, it is cleaned by a sticky roller and then to the area of the coating head, the second acrylic resin, the second diffusion particles, the second After the coating solution mixed with the second curing agent is coated on the other side of the substrate with a micro-gravure roller with a mesh number of 110, the solvent is evaporated in a drying oven, and the coating solution is cured on the other side of the substrate to form a back coating , and then through winding to obtain the finished diffusion film. The length of the oven is 20-60m, preferably a five-section sectional oven, the temperature setting range of the oven is 70-110°C, and the production speed is 15-35m / min.

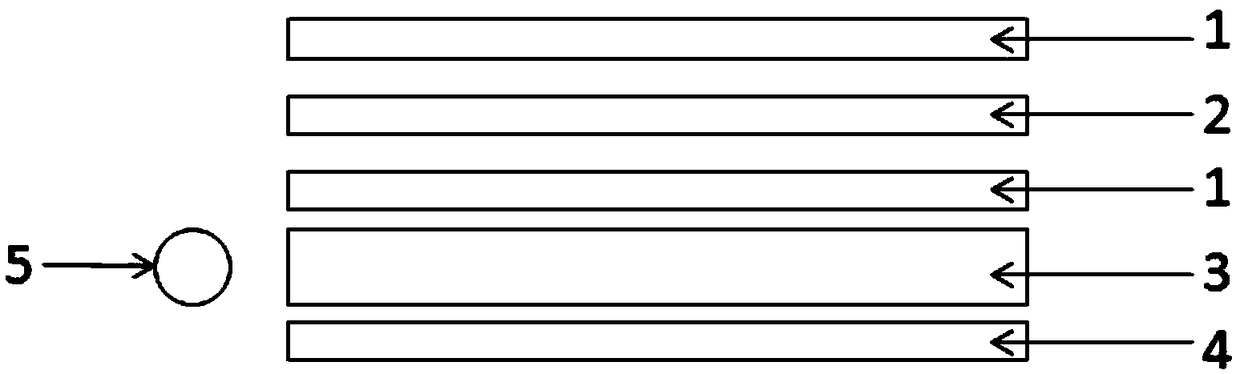

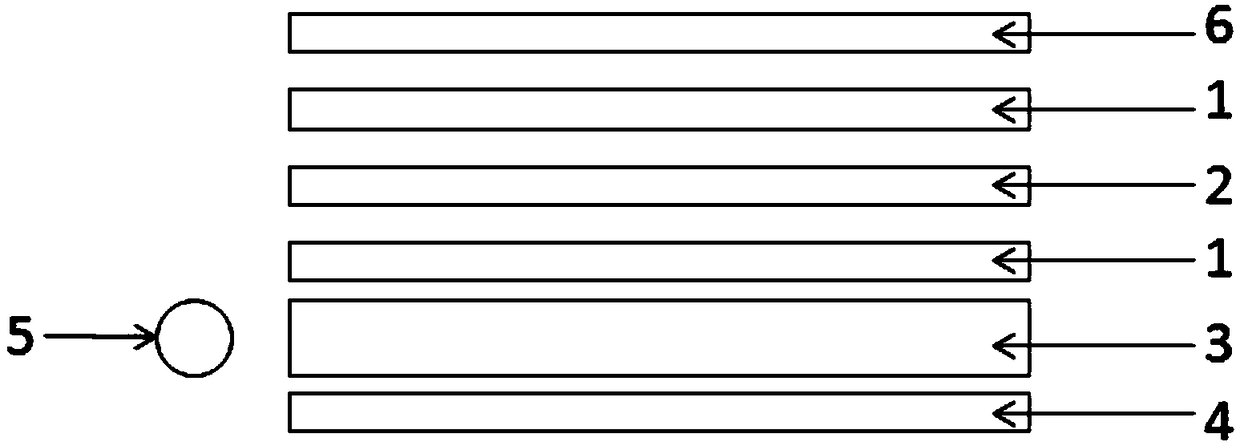

[0042] The present invention also provides a backlight module and a liquid crystal display, such as figure 2 As shown, the backlight ...

Embodiment 1

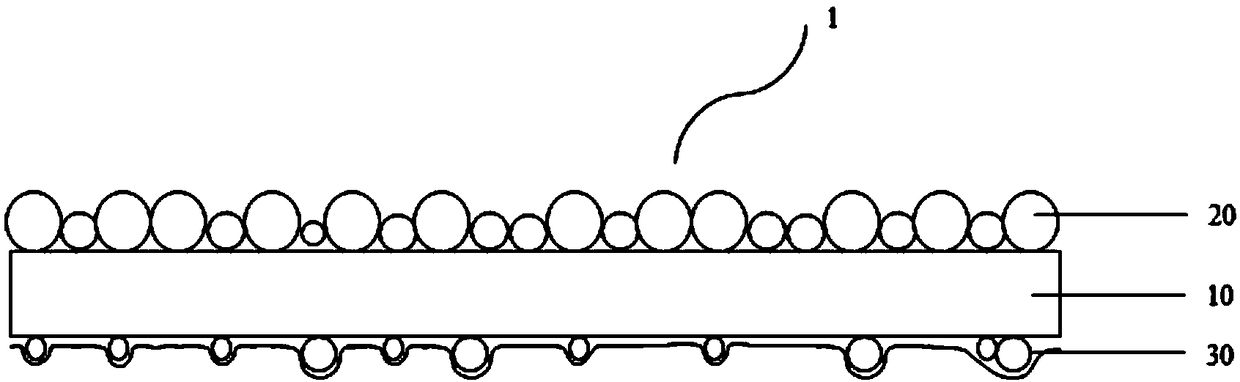

[0045] A kind of anti-scratch diffusion film 1, such as figure 1 As shown, it includes a substrate 10, a diffusion layer 20 disposed on one side of the substrate, and a backcoat layer 30 disposed on the other side of the substrate. The diffusion layer is formed by coating and curing the coating solution of the following components on the surface of the substrate. The coating liquid components are: 22 parts by weight of acrylic resin AA-911 (manufactured by Aekyung Chemical, TG point about 40°C), 3.2 parts by weight of 5 μm polydisperse PMMA particles (CV value 40%), 0.5 parts by weight of 15 μm Medium dispersed PMMA particles (CV value 30%), 12 parts by weight of ethyl acetate, 18 parts by weight of butyl acetate, 1.3 parts by weight of isocyanate curing agent, 0.2 parts by weight of dispersant BYK-111, 0.05 parts by weight of fluid Leveling agent BYK333. Wherein, the particle strength of the PMMA diffusion particle composition is 20 MPa, the degree of crosslinking is 25%, t...

Embodiment 2

[0047] An anti-scratch diffusion film comprises a base material, a diffusion layer arranged on one side of the base material and a back coating layer arranged on the other side of the base material. The diffusion layer is formed by coating and curing the coating solution of the following components on the surface of the substrate. The coating solution components are: 48 parts by weight of acrylic resin AA-911 (manufactured by Aekyung Chemical, TG point about 40°C), 5.0 parts by weight of 5 μm polydisperse PMMA particles (CV value 45%), 4.1 parts by weight of 10 μm Monodisperse PMMA particle (CV value 3%), disperse PMMA particle (CV value 15%) in the 20 μm of 2 weight parts, the ethyl acetate of 20 weight parts, the butyl acetate of 30 weight parts, the isocyanate solidifying agent of 2.3 weight parts , 0.2 parts by weight of dispersant BYK-111, 0.05 parts by weight of leveling agent BYK333. Wherein, the particle strength of the PMMA diffusion particle composition is 24 MPa, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com