Three-return-stroke vacuum drying tower

A three-pass, drying tower technology, applied in the direction of drying, drying machine, drying solid materials, etc., can solve the problems of high hot air temperature, low exhaust efficiency, poor quality, etc., and achieve stable and reliable operation and high lifting height , the effect of large transport volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

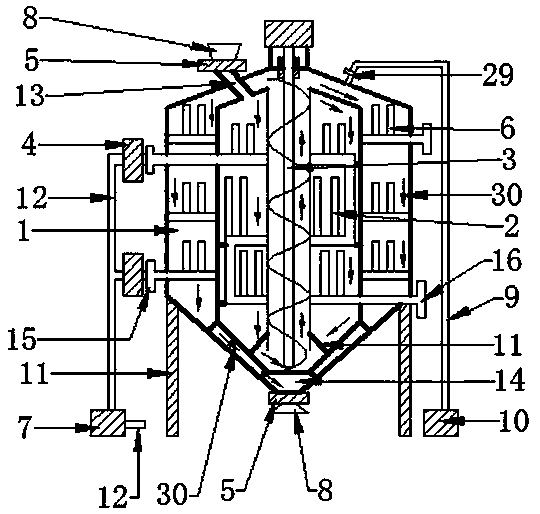

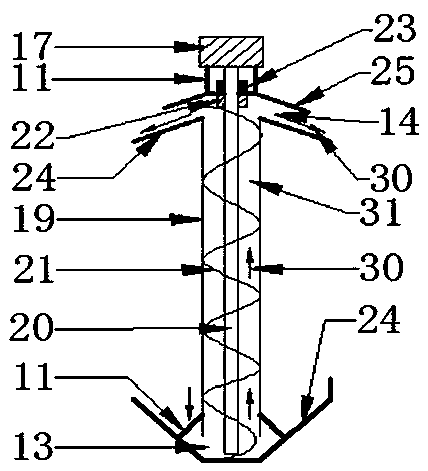

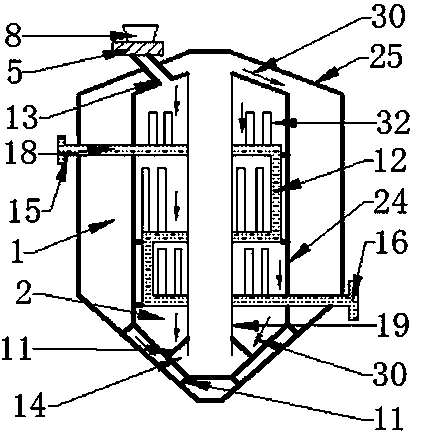

[0173] Such as figure 1 The shown three-pass vacuum drying tower includes outer drying chamber (1), inner drying chamber (2), lifting device (3), heat circulation pump (4), discharge valve (5), heat exchange device (6) , heating device (7), hopper (8), air duct (9), vacuum unit (10), bracket (11), heat pipe (12).

[0174] The bracket (11) is a bracket (11) made of I-shaped steel, or a bracket (11) made of a triangle iron, or a bracket (11) made of a metal strip.

[0175] The outer drying bin (1) is supported and fixed on the ground by a bracket (11), and the outer drying bin (1) is fixed on the bracket (11); the bracket (11) supporting and fixing the outer drying bin (1) is an I-shaped Support (11) made of steel.

[0176] The inner drying bin (2) is installed in the outer drying bin (1), and the inner drying bin (2) and the outer drying bin (1) are supported and fixed by brackets (11); the outer drying bin (1) and the outer drying bin (1) are supported and fixed. The suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com