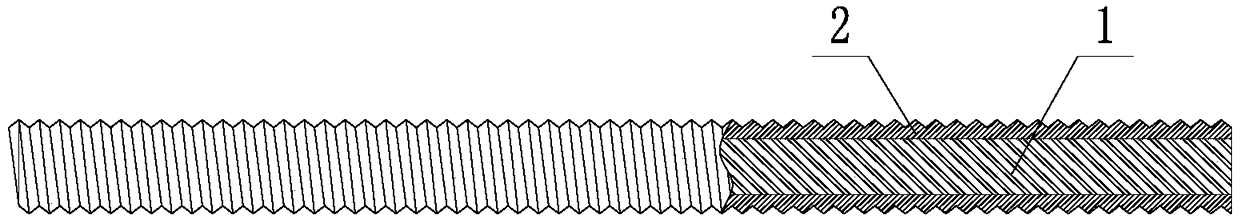

Heat bridge breaking screwed fitting and heat bridge breaking method

A threaded connection and heat insulation technology, applied in the field of building insulation, can solve the problems of indoor heat loss and large thermal conductivity, and achieve the effects of light weight, low thermal conductivity and low heat transfer added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A thermally broken bridge approach such as figure 2 As shown, the heat-breaking bridge threaded connector 3 is used to block the connection heat bridge between the pre-connected external component 4 and the cast-in-place concrete member 5; Buried and fixed in the cast-in-place concrete component 5, and the pre-embedded depth is set according to the mechanical requirements, and then the other end of the heat-insulating bridge threaded connector 3 is fixed to the pre-connected external component 4, and the fastener is the same as the heat-insulating bridge. The bridge threaded connector 3 matches the nut 6 .

Embodiment 2

[0034] A thermally broken bridge approach such as image 3 As shown, the heat-breaking bridge threaded connector 3 is used to block the connection thermal bridge between the pre-connected external component 4 and the prefabricated concrete component 7; Embed expansion bolts 8 or chemical anchors equal to the diameter of the openings in the openings, and then use double-pass long nuts 9 to securely connect one end of the heat-breaking bridge threaded connector 3 with expansion bolts 8 or chemical anchors, and finally The other end of the heat-breaking bridge threaded connection 3 is fixedly connected to the pre-connected external component 4 , and the fastener is a nut 6 matching with the heat-breaking bridge threaded connection 3 .

Embodiment 3

[0036] A thermally broken bridge approach such as Figure 4 As shown, the heat-breaking bridge threaded connector 3 is used to block the connection thermal bridge between the pre-connected external component 4 and the sheet metal component 10; Then pass one end of the heat-breaking bridge threaded connector 3 through the opening, and then firmly connect the heat-breaking bridge threaded connector 3 with the metal plate member 10, and the fasteners are matched with the heat-breaking bridge threaded connector 3 Nut 6 , and finally fix the other end of the heat-breaking bridge threaded connector 3 to the pre-connected external member 4 , and the fastener is the nut 6 that matches the heat-breaking bridge threaded connector 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com