Method for plating BaTiO3 ceramic surface with copper

A ceramic surface, copper plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problem that chemical copper plating is difficult to achieve, the quality of the coating is difficult to meet the technical requirements of the application, and the quality of the coating is unstable, etc. problems, to achieve the effect of reliable quality and quality stability, easy automatic operation, and good plating reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

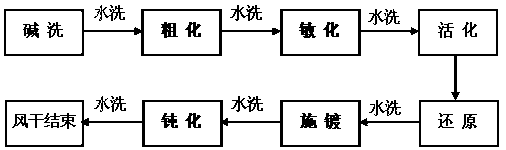

Method used

Image

Examples

Embodiment 1

[0067] For Φ35mm×50mm cylinder BaTiO 3 Copper plating on ceramic surface for 30min

[0068] Solution formula: ①Alkaline washing solution: NaOH 30g / L, Na 3 PO 4 45g / L, Na 2 CO 3 25g / L, mixed with distilled water; ②Coarse solution: CrO 3 140g / L, H 2 SO 4 (98%) 95mL / L, distilled water for liquid preparation; ③sensitizing solution: SnCl 2 10g / L, HCl (36-38%) 50mL / L, mixed with distilled water; ④Activating solution: PdCl 2 0.6g / L, HCl (36-38%) 10mL / L, distilled water for solution; ⑤Reducing solution: HCHO (37-40%) 100mL / L, distilled water for solution; ⑥Copper plating solution: CuSO 4 • 5H 2 O 20 g / L, C 10 H 16 N 2 O 8 22g / L, C 4 O 6 H 4 KNa 16g / L, HCHO (37-40%) 12mL / L, NaH 2 PO 2 25 g / L, C 4 H 4 N 2 OS 20 g / L, K 4 Fe(CN) 6 0.4g / L, NaOH 14g / L, mixed with distilled water; ⑦passivation melt: CrO 3 80 g / L, NaCl 1.0 g / L, H 2 SO 4 25 ml / L, mixed with distilled water.

[0069] Implementation operation: ①Alkaline washing: soak the workpiece in an alkaline washing solution at a temperat...

Embodiment 2

[0072] For Φ35mm×50mm cylinder BaTiO 3 Copper plating on ceramic surface for 60min

[0073] Solution formula: ①Alkaline washing melt: NaOH 30g / L, Na 3 PO 4 45g / L, Na 2 CO 3 25g / L, mixed with distilled water; ②Coarse solution: CrO 3 150g / L, H 2 SO 4 (98%) 100mL / L, distilled water for liquid preparation; ③sensitizing solution: SnCl 2 10g / L, HCl (36-38%) 50mL / L, mixed with distilled water; ④Activating solution: PdCl 2 0.6g / L, HCl (36-38%) 10mL / L, distilled water for solution; ⑤Reducing solution: HCHO (37-40%) 100mL / L, distilled water for solution; ⑥Copper plating solution: CuSO 4 • 5H 2 O 15 g / L, C 10 H 16 N 2 O 8 20g / L, C 4 O 6 H 4 KNa 15g / L, HCHO (37-40%) 12mL / L, NaH 2 PO 2 20 g / L, C 4 H 4 N 2 OS 15 g / L, K 4 Fe(CN) 6 0.2g / L, NaOH 14g / L, mixed with distilled water; ⑦passivation melt: CrO 3 80 g / L, NaCl 1.0 g / L, H 2 SO 4 25 ml / L, mixed with distilled water.

[0074] Implementation operation: ①Alkaline washing: soak the workpiece in an alkaline washing solution at a temperature...

Embodiment 3

[0077] For Φ35mm×50mm cylinder BaTiO 3 Copper plating on ceramic surface for 90min

[0078] Solution formula: ①Alkaline washing melt: NaOH 30g / L, Na 3 PO 4 45g / L, Na 2 CO 3 25g / L, mixed with distilled water; ②Coarse solution: CrO 3 160g / L, H 2 SO 4 (98%) 105mL / L, distilled water for liquid; ③sensitizing solution: SnCl 2 10g / L, HCl (36-38%) 50mL / L, mixed with distilled water; ④Activating solution: PdCl 2 0.6g / L, HCl (36-38%) 10mL / L, distilled water for solution; ⑤Reducing solution: HCHO (37-40%) 100mL / L, distilled water for solution; ⑥Copper plating solution: CuSO 4 • 5H 2 O 15 g / L, C 10 H 16 N 2 O 8 18g / L, C 4 O 6 H 4 KNa 14g / L, HCHO (37-40%) 10mL / L, NaH 2 PO 2 18 g / L, C 4 H 4 N 2 OS 14 g / L, K 4 Fe(CN) 6 0.3g / L, NaOH 14g / L, mixed with distilled water; ⑦passivation melt: CrO 3 80 g / L, NaCl 1.0 g / L, H 2 SO 4 25 ml / L, mixed with distilled water.

[0079] Implementation operation: ①Alkaline washing: soak the workpiece in an alkaline washing solution at a temperature of 50℃ for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com