A kind of martensitic antibacterial stainless steel

An antibacterial stainless steel and martensite technology, applied in the field of stainless steel materials, can solve the problem of low antibacterial concentration, and achieve the effects of inhibiting bacterial proliferation, strong antibacterial performance, and increasing antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

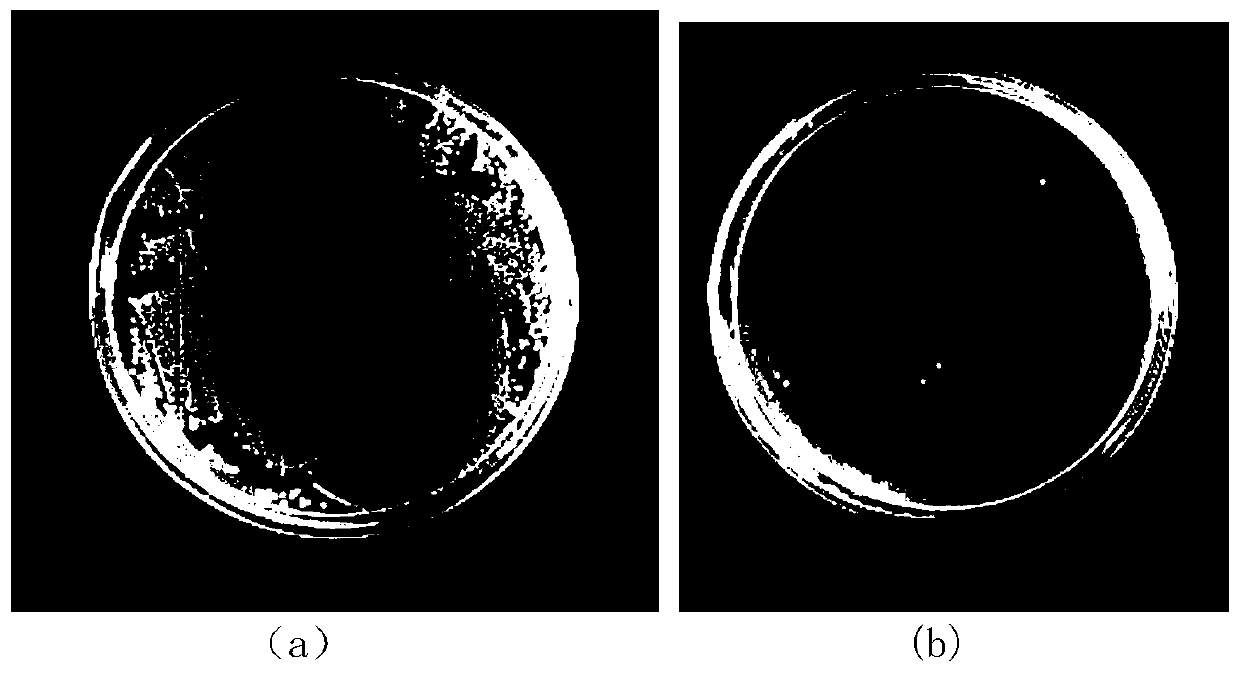

Image

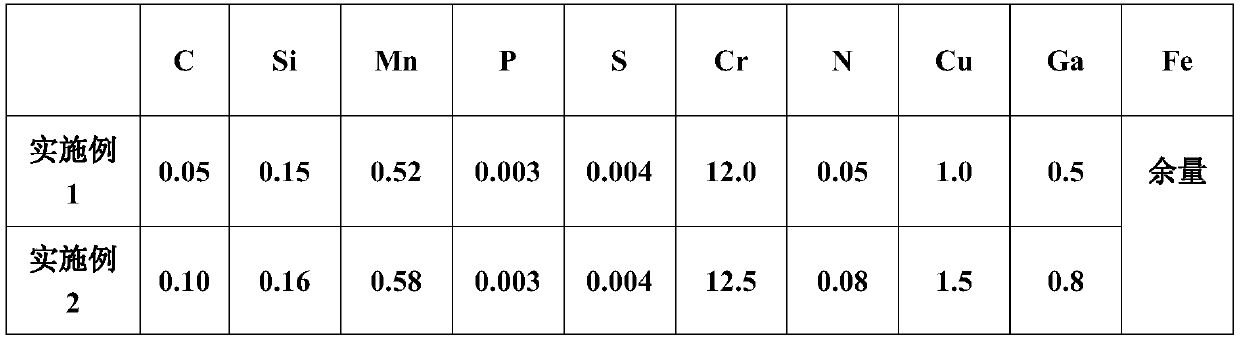

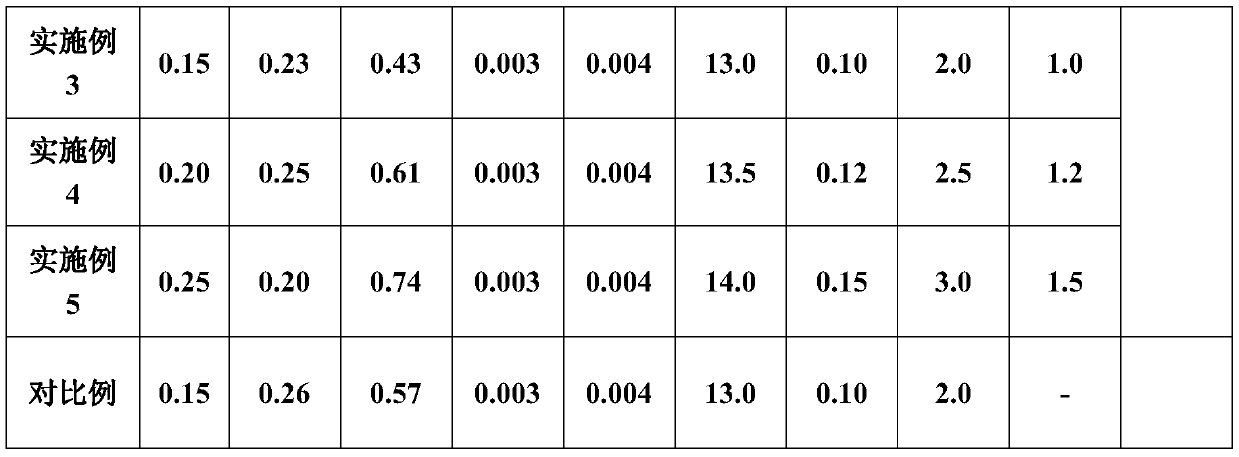

Examples

Embodiment 1

[0030] The heat treatment process of the antibacterial stainless steel of embodiment 1 is:

[0031] Incubate at 900 °C for 1 h, and after water cooling to room temperature, the Ga in the steel is in a supersaturated state;

[0032] According to "JIS Z 2801-2000 "Antibacterial Processed Products - Antibacterial Test Methods and Antibacterial Effects", GB / T2591-2003 "Antibacterial Properties of Antibacterial Plastics Test Methods and Antibacterial Effects" and other standards, and choose a bacterial concentration of 10 7 CFU / mL. The antibacterial properties of typical bacteria were tested, and the results were:

[0033] (1) Antibacterial rate to Eschericher Coli: ≥91.4%;

[0034] (2) Antibacterial rate against Staphylococcus aureus: ≥92.5%.

Embodiment 2

[0036] In the present embodiment, the heat treatment process of antibacterial stainless steel is:

[0037] Incubate at 940°C for 2h, and after water cooling to room temperature, make the Ga in the steel in a supersaturated state; then keep at 350°C for 4h to precipitate a sufficient volume fraction of Ga-rich phase in the steel, and air-cool to room temperature. For typical bacteria (bacteria concentration of 10 7 CFU / mL) antibacterial performance test, the results are:

[0038] (1) Antibacterial rate to Eschericher Coli: ≥94.8%;

[0039] (2) Antibacterial rate against Staphylococcus aureus: ≥95.4%.

Embodiment 3

[0041] In the present embodiment, the heat treatment process of antibacterial stainless steel is:

[0042] Incubate at 960°C for 3h, and after water cooling to room temperature, make the Ga in the steel in a supersaturated state; then keep at 200°C for 5h to precipitate a sufficient volume fraction of Ga-rich phase in the steel, and air-cool to room temperature. For typical bacteria (bacteria concentration of 10 7 CFU / mL) antibacterial performance test, the results are:

[0043] (1) Antibacterial rate to Eschericher Coli: ≥95.7%;

[0044] (2) Antibacterial rate against Staphylococcus aureus: ≥96.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com