An antibacterial stainless steel for electrical equipment

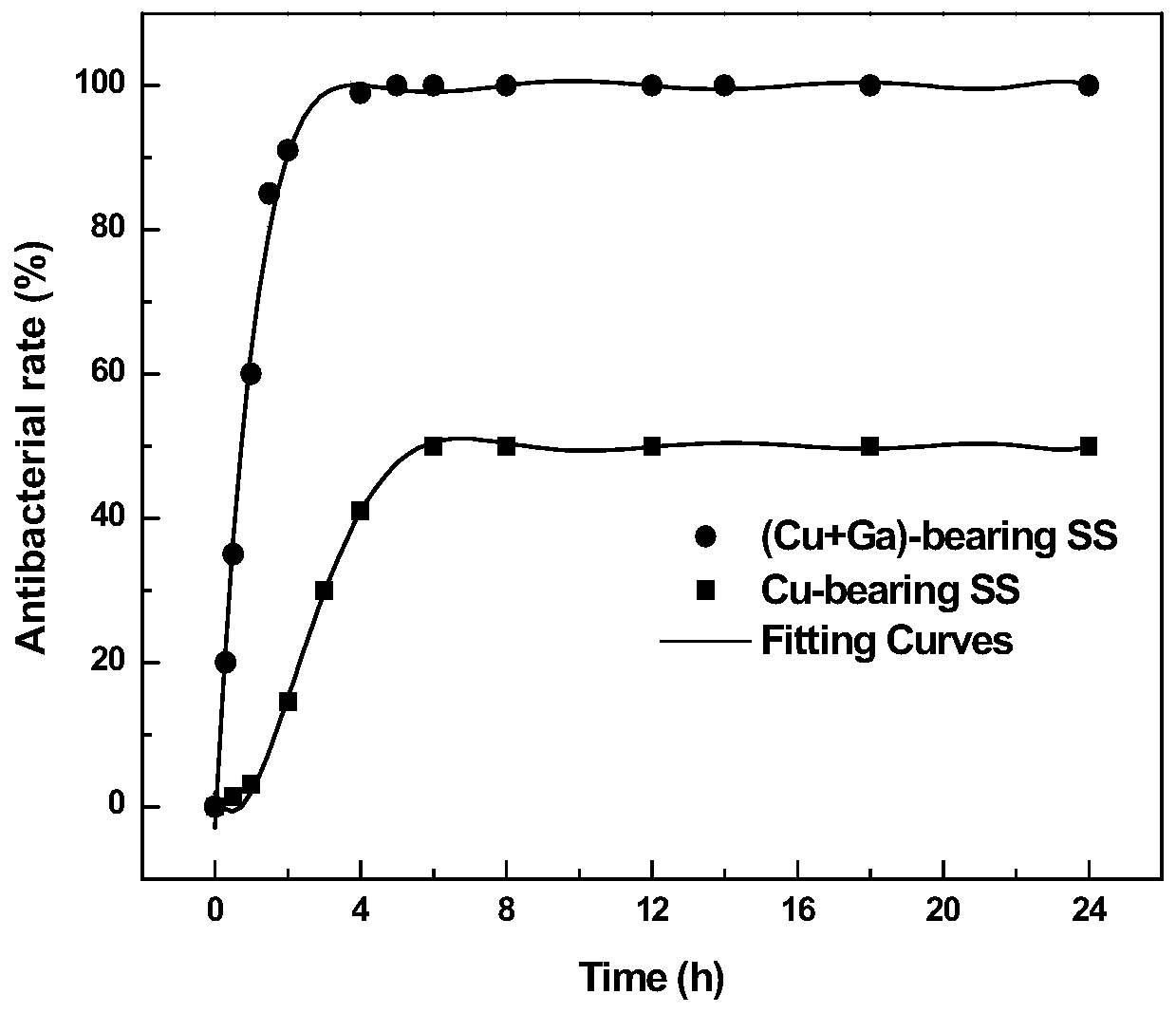

A technology of antibacterial stainless steel and electrical equipment, applied in the field of stainless steel materials, can solve the problems of low antibacterial efficiency, achieve the effects of improving antibacterial efficiency, increasing sterilization rate, strong antibacterial performance and timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

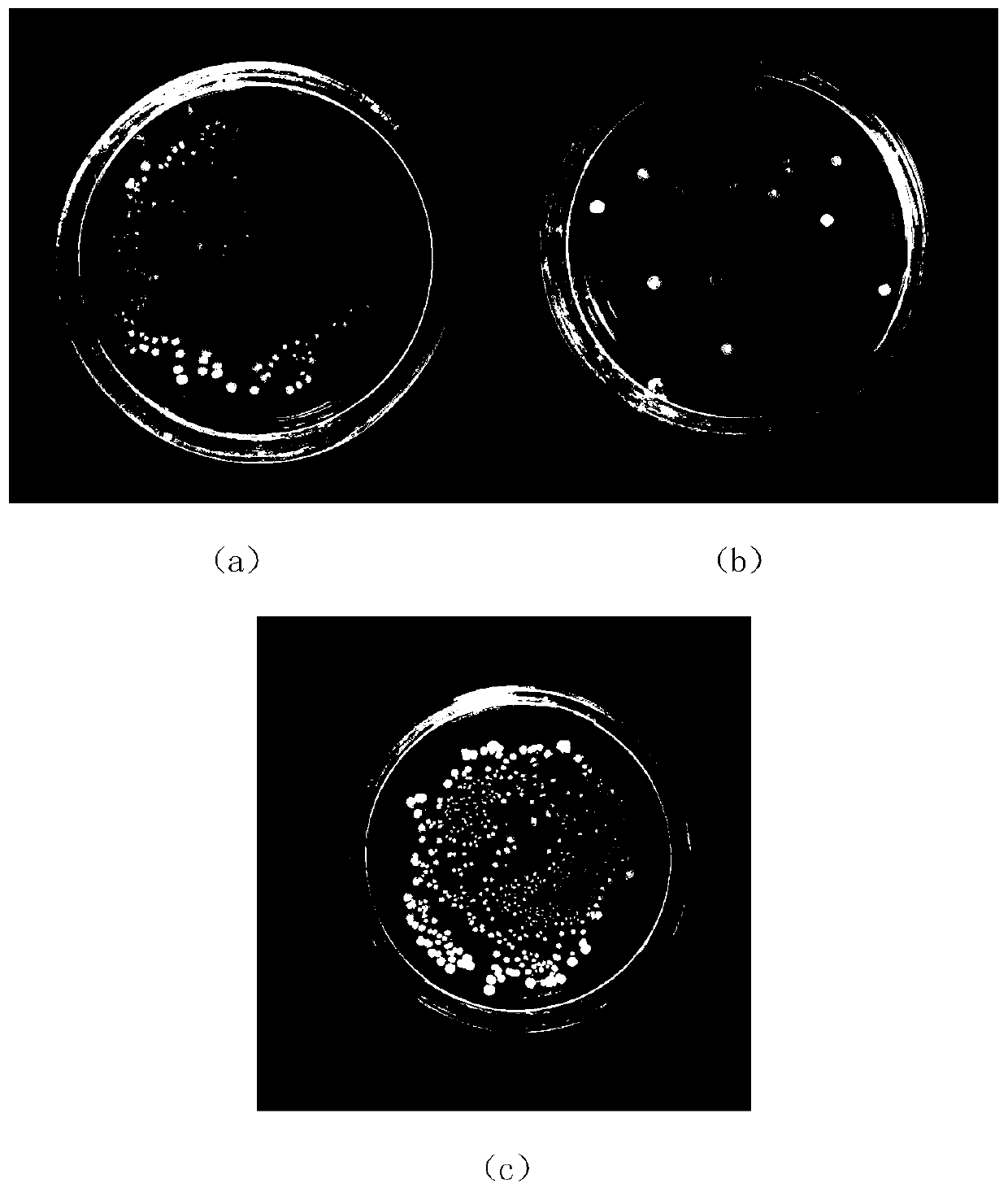

Image

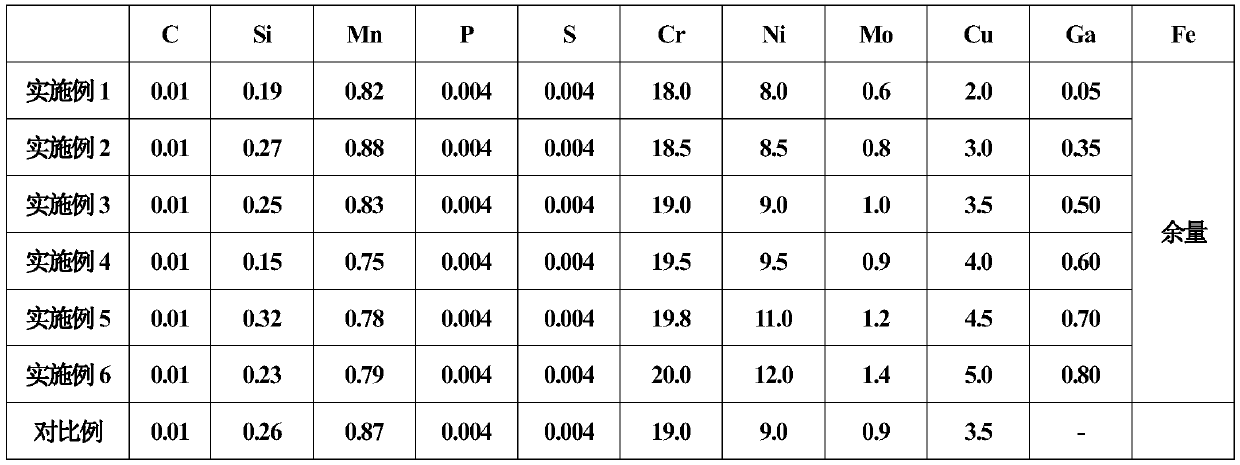

Examples

Embodiment 1

[0029] The heat treatment process of the antibacterial stainless steel of embodiment 1 is:

[0030] Insulate at 1055°C for 1 hour, and cool to room temperature with water to make Ga in the steel supersaturated; then hold at 590°C for 5 hours to precipitate Ga-rich and Cu-rich phases in the steel, and cool to room temperature with water.

[0031] According to the above-mentioned antibacterial detection method, the antibacterial performance of the mixed bacteria was detected, and the antibacterial rate result was 94.4%.

Embodiment 2

[0033] In the present embodiment, the heat treatment process of antibacterial stainless steel is:

[0034] Insulate at 1060°C for 2 hours, and cool to room temperature with water to make Ga in the steel supersaturated; then hold at 620°C for 6 hours to precipitate Ga-rich and Cu-rich phases in the steel, and cool to room temperature in water. According to the above-mentioned antibacterial detection method, the antibacterial performance of the mixed bacteria was detected, and the antibacterial rate result was 95.0%.

Embodiment 3

[0036] In the present embodiment, the heat treatment process of antibacterial stainless steel is:

[0037] Insulate at 1060°C for 3 hours, and cool to room temperature with water to make Ga in the steel supersaturated; then hold at 700°C for 4 hours to precipitate a sufficient volume fraction of Ga-rich and Cu-rich phases in the steel, and cool to room temperature in air. According to the above-mentioned antibacterial detection method, the antibacterial performance of the mixed bacteria was detected, and the antibacterial rate was 95.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com