Modified urea-formaldehyde furan resin

A technology of urea-formaldehyde furan resin and urea-formaldehyde furan, which is applied in the field of organic synthetic resins and can solve problems such as poor environmental performance, pungent odor, and high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

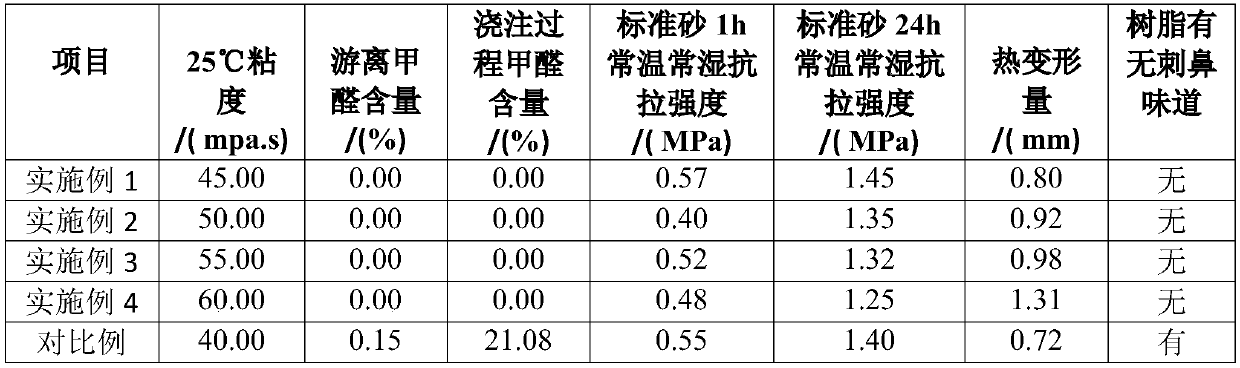

Examples

Embodiment 1

[0029] Citral 18%, urea 5%, furfuryl alcohol 73%, sodium hydroxide 0.3%, hydrochloric acid 0.21%, methanol 3.29%, silane 0.2%.

[0030] Ⅰ. Add 900kg citral and 250kg urea into the reaction kettle, start stirring and add 700kg furfuryl alcohol, then slowly add sodium hydroxide, slowly heat up to 80-100°C and then reflux for 70-80min.

[0031] Ⅱ. Add 300kg of furfuryl alcohol and lower the temperature to 75-80°C for vacuum dehydration, then add 1850kg of furfuryl alcohol, slowly add hydrochloric acid, heat up to 80-100°C and reflux for 80-90min.

[0032] Ⅲ. Cool down and add 800kg of furfuryl alcohol, 164.5kg of methanol, and 10kg of silane, stir for 30min, add sodium hydroxide to adjust the pH value to neutral. After cooling to room temperature, discharge.

Embodiment 2

[0034] Citral 18%, urea 6%, furfuryl alcohol 70%, sodium hydroxide 0.32%, hydrochloric acid 0.25%, methanol 5.18%, silane 0.25%.

[0035] Ⅰ. Add 900kg citral and 300kg urea into the reaction kettle, start stirring and add 700kg furfuryl alcohol, then slowly add sodium hydroxide, slowly heat up to 80-100°C and then reflux for 70-80min.

[0036] Ⅱ. Add 300kg of furfuryl alcohol and lower the temperature to 75-80°C and vacuum dehydrate, then add 1700kg of furfuryl alcohol, slowly add hydrochloric acid, heat up to 80-100°C and reflux for 80-90min.

[0037] Ⅲ. Cool down and add 800kg of furfuryl alcohol, 259kg of methanol, and 12.5kg of silane, stir for 30min, add sodium hydroxide to adjust the pH value to neutral. After cooling to room temperature, discharge.

Embodiment 3

[0039] Citral 21%, urea 8%, furfuryl alcohol 67%, sodium hydroxide 0.35%, hydrochloric acid 0.45%, methanol 3.0%, silane 0.2%.

[0040] Ⅰ. Add 1050kg citral and 400kg urea into the reaction kettle, start stirring and add 700kg furfuryl alcohol, then slowly add sodium hydroxide, slowly raise the temperature to 80-100°C and then reflux for 70-80min.

[0041] Ⅱ. Add 300kg of furfuryl alcohol and lower the temperature to 75-80°C for vacuum dehydration, then add 1550kg of furfuryl alcohol, slowly add hydrochloric acid, heat up to 80-100°C and reflux for 80-90min.

[0042] Ⅲ. Cool down and add 800kg of furfuryl alcohol, 150kg of methanol and 10kg of silane, stir for 30min, add sodium hydroxide to adjust the pH value to neutral. After cooling to room temperature, discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com