Polymerization reaction type formaldehyde catching agent and preparation method thereof

A formaldehyde scavenger, polymerization technology, applied in aldehyde/ketone condensation polymer adhesives, adhesive types, adhesive additives, etc., can solve the problems of secondary pollution, preparation process, complexity, etc. effect of improving water resistance and bond strength, shortening curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

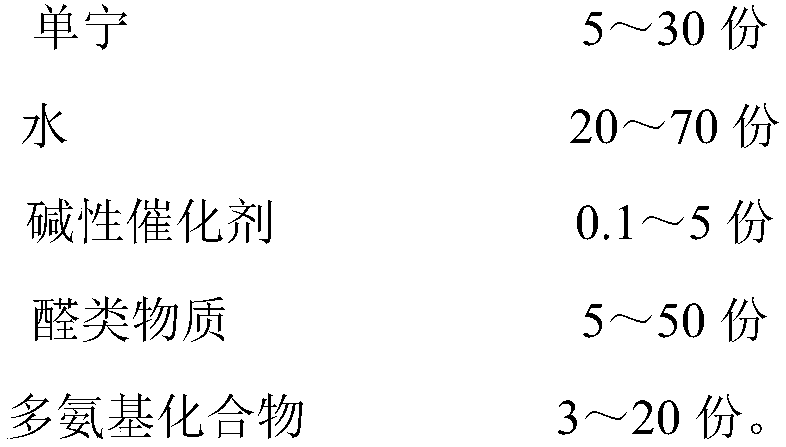

Method used

Image

Examples

Embodiment 1

[0025] A polymerization reaction type formaldehyde scavenger, based on the total mass of the formaldehyde scavenger raw material as 100%, each component and mass percentage in the raw material are as follows:

[0026]

[0027] A kind of preparation method of polyreaction type formaldehyde scavenger, concrete steps are as follows:

[0028] (1) Add 300 kg of tannin, 380 kg of water, and 15 kg of sodium hydroxide into the reaction kettle, mechanically stir at 80r / min for 15 minutes, heat to 90°C, slowly add 200 kg of glyoxal, and keep warm Stir for 1h.

[0029] (2) Add 105 kg of polyacrylamide to the reaction product obtained in step (1), and mechanically stir at 80°C for 2 hours at a speed of 68r / min, stir and cool to room temperature, and discharge to obtain a polymerization reaction formaldehyde scavenger . The properties of the formaldehyde scavenger are shown in Table 1.

Embodiment 2

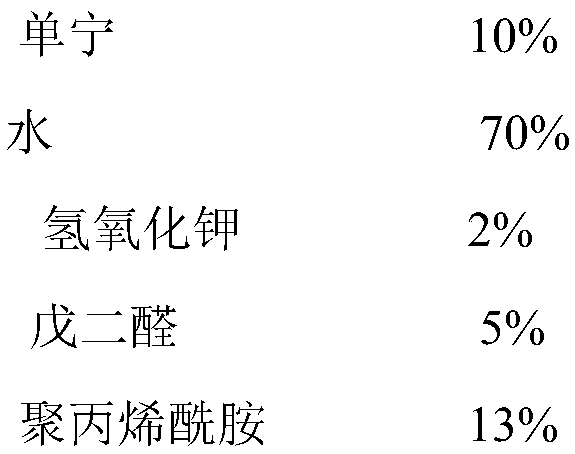

[0031] A polymerization reaction type formaldehyde scavenger, based on the total mass of the formaldehyde scavenger raw material as 100%, each component and mass percentage in the raw material are as follows:

[0032]

[0033] A kind of preparation method of polyreaction type formaldehyde scavenger, described method concrete steps are as follows:

[0034] (1) Add 100 kg of tannin, 700 kg of water, and 20 kg of potassium hydroxide into the reaction kettle, mechanically stir at 80r / min for 15 minutes, heat to 60°C, slowly add 50 kg of glutaraldehyde, and keep warm Stir for 3h.

[0035] (2) Add 130 kg of polyacrylamide to the reaction product obtained in step (1), and mechanically stir at 70°C for 4 hours at a speed of 68r / min, stir and cool to room temperature, and discharge to obtain a polymerization-type formaldehyde scavenger . The properties of the formaldehyde scavenger are shown in Table 1.

Embodiment 3

[0036] Embodiment 3: a kind of polyreaction type formaldehyde scavenger, take the gross mass of described formaldehyde scavenger raw material as 100%, each component and mass percentage in the raw material are as follows:

[0037]

[0038]

[0039] A kind of preparation method of polyreaction type formaldehyde scavenger, described method concrete steps are as follows:

[0040] (1) Add 50 kg of tannin, 699 kg of water, and 1 kg of sodium hydroxide into the reaction kettle, mechanically stir at 80r / min for 15 minutes, heat to 80°C, slowly add 50 kg of glutaraldehyde, and keep warm Stir for 2h.

[0041] (2) Add 200 kg of polyacrylamide to the reaction product obtained in step (1), and mechanically stir at 85°C for 1 hour at a speed of 68r / min, stir and cool to room temperature, and discharge to obtain a polymerization reaction formaldehyde scavenger . The properties of the formaldehyde scavenger are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com