A method for manufacturing rigid heat-insulating tile body by additive manufacturing method

A technology of additive manufacturing and heat insulation tiles, which is applied in the direction of manufacturing tools, additive processing, ceramic molding machines, etc., can solve problems such as uneven density, and achieve the effect of uniform density, guaranteed accuracy, and accurate thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

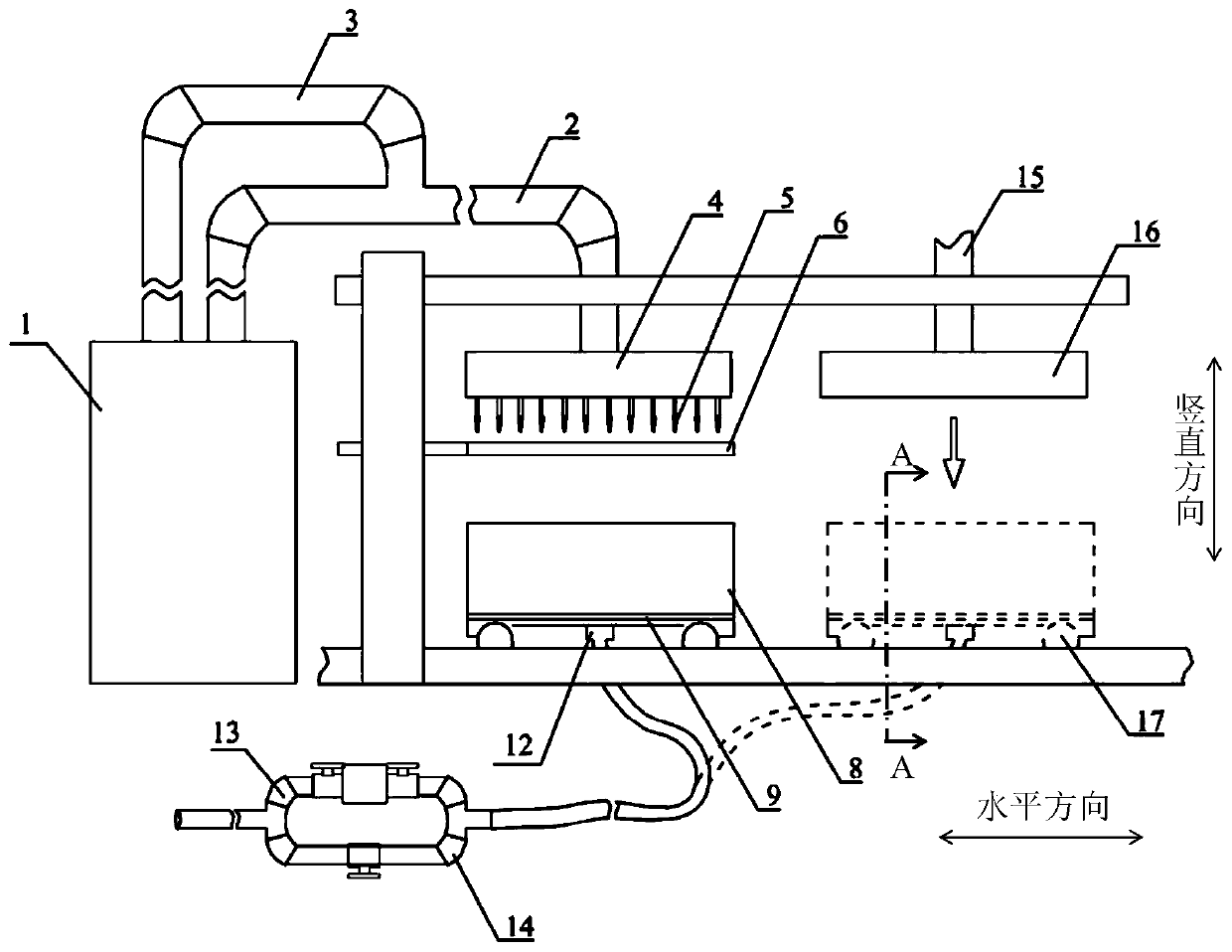

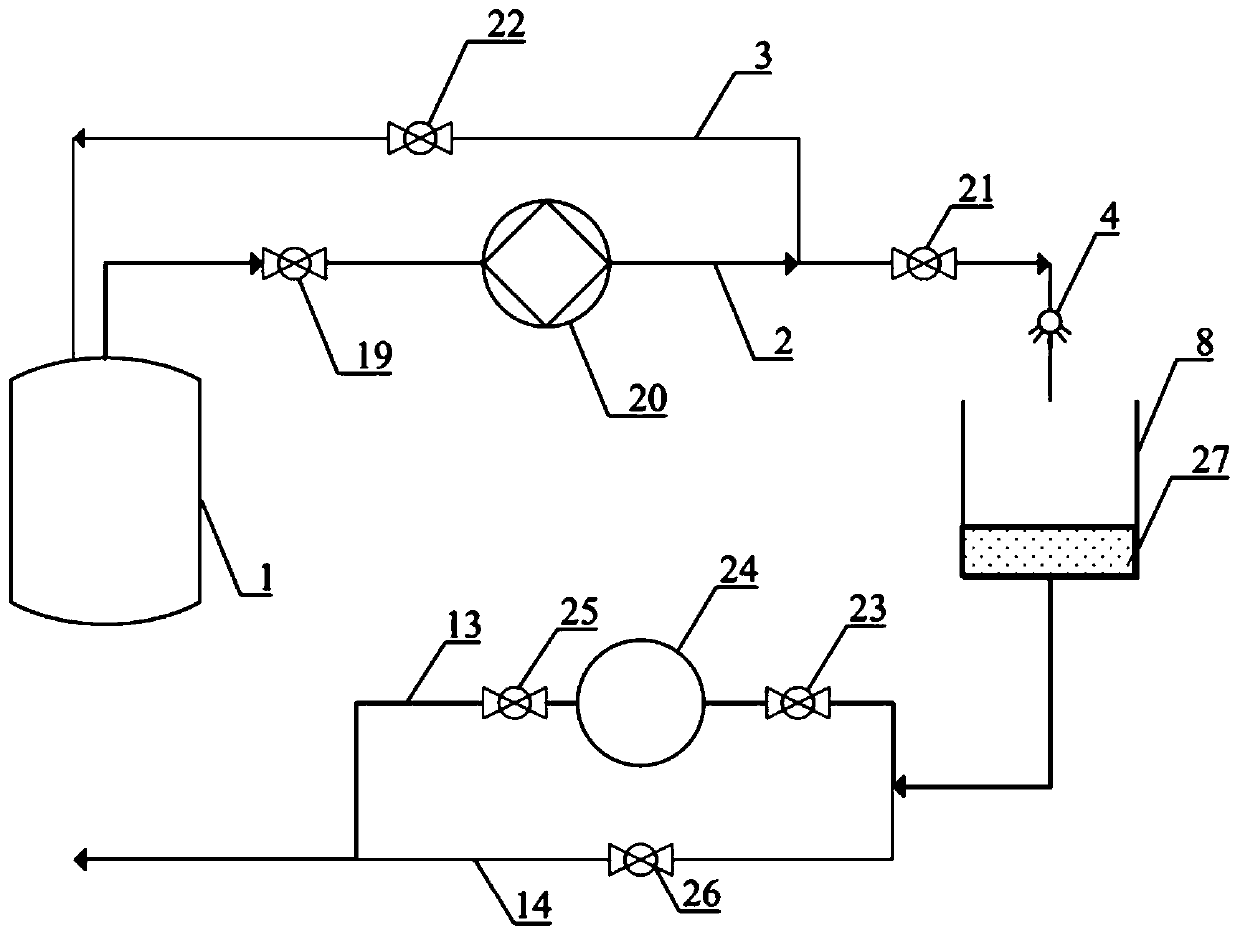

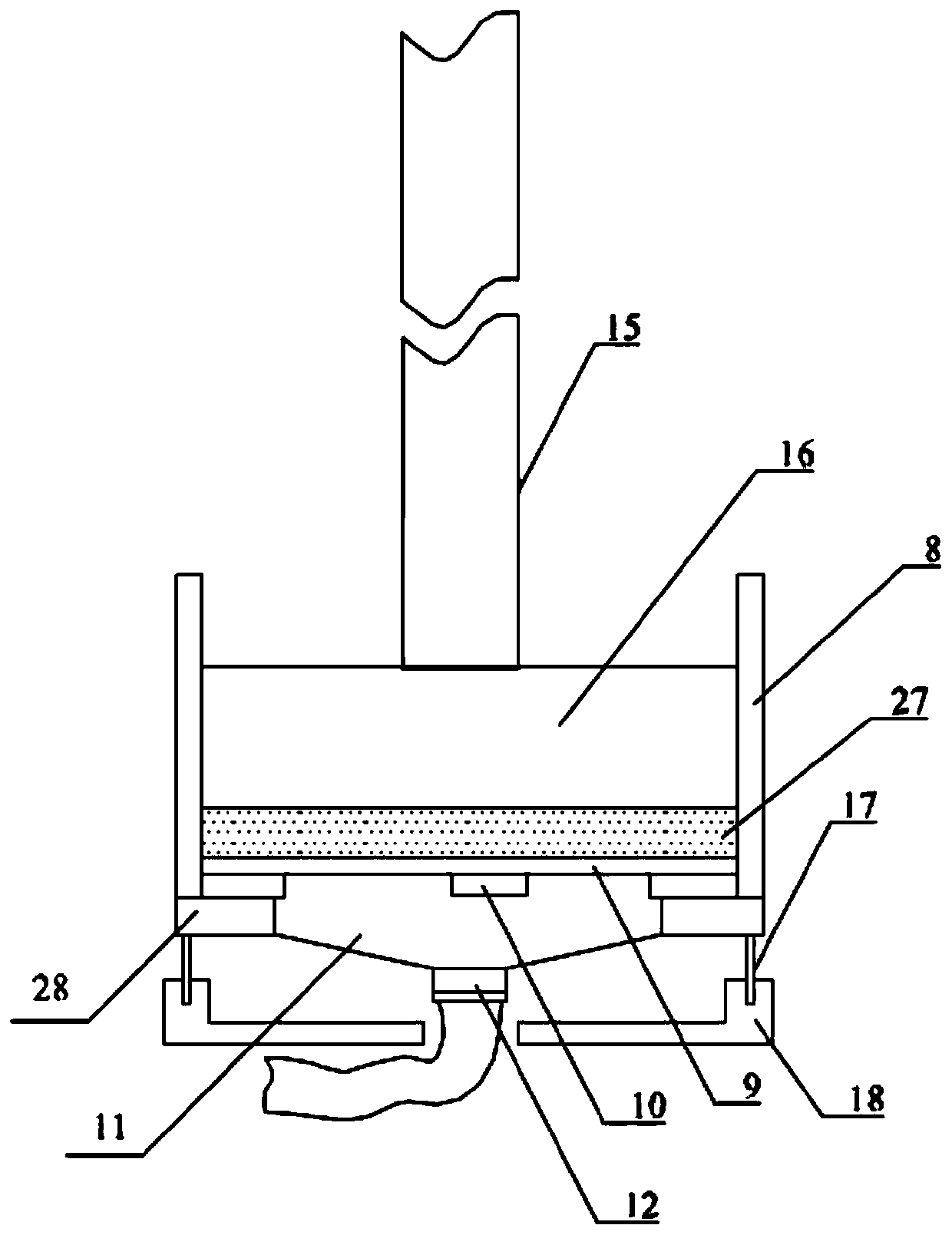

[0076] Rigid heat-insulation tile blank body is manufactured by a device for additively manufacturing rigid heat-insulation tile blank body, said device for additively manufacturing rigid heat-insulation tile blank body, such as figure 1 shown. The device for additively manufacturing a rigid heat-insulating tile body includes a feeding system, a filter container, a drain pipe, a pressurizing device and an automatic control system (PLC controller, a first displacement sensor, a second displacement sensor, a pressure sensor and solenoid valve).

[0077] The filter container includes a peripheral wall, a bottom plate, a bottom net (30 mesh steel wire mesh), 3 lath-shaped reinforcing ribs arranged in parallel (through holes are provided on the reinforcing ribs) and a liquid collecting tank arranged below the reinforcing ribs. part, the liquid outlet of the liquid collection part communicates with the liquid discharge pipe, and the liquid discharge pipe includes a main liquid disc...

Embodiment 2

[0083] Example 2 is basically the same as Example 1, except that the pH of the slurry is not adjusted to 10 with concentrated ammonia water.

Embodiment 3

[0085] Embodiment 3 is basically the same as Embodiment 1, except that in the device used in Embodiment 3 for additive manufacturing of rigid heat-insulating tile blanks: the distance between the centers of every two adjacent through holes is 8mm.

[0086] The density test was carried out on the 7 slurry layers included in the rigid heat-insulating tile body manufactured in this embodiment, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com