Sugarcane squeezing roller shaft restoration process

A pressing roller and process technology, which is applied in the field of sugarcane pressing roller shaft repair technology in sugar factories, can solve problems such as low hardness, low durability, and unstable pressing quality, and achieve good welding quality, good durability, and simple repair methods easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

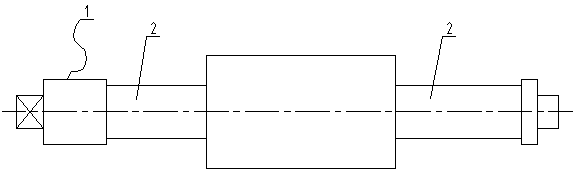

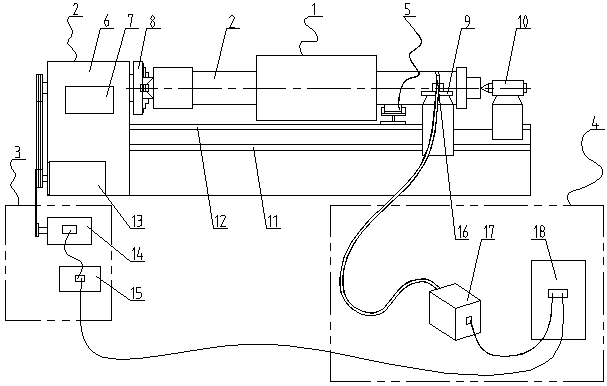

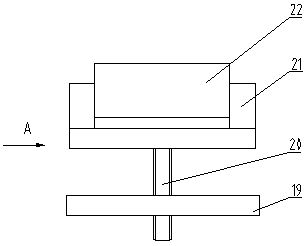

[0050] See attached Figure 1~8 As shown, the sugarcane squeezing roller repair process of the present invention is realized by the following scheme:

[0051] The process steps of the sugarcane squeezing roller repair process of the present invention are as follows:

[0052] 1) Pre-heat treatment: Put it in a heating furnace and heat it at a temperature of 100°C;

[0053] 2) Surface cleaning: Use a manual welding torch to clean the surface of the press roll obtained by the above step 1) preheating to remove the rust on the surface of the roll and the moisture and sludge that infiltrate the inner tissue of the roll;

[0054] 3) Turning removal: lathe turning to remove the fatigue layer of the roller surface layer;

[0055] 4) Measurement: Measure the worn squeeze roller to obtain the amount of wear and confirm the welding thickness;

[0056] 5) Welding repair: Welding repairs on the worn press rolls by using a welding machine on a lathe, leaving a machining allowance of 2-5mm for the rep...

Embodiment 2

[0070] See attached Figure 1~8 As shown, the sugarcane squeezing roller repair process of the present invention is realized by the following scheme:

[0071] The process steps of the sugarcane squeezing roller repair process of the present invention are as follows:

[0072] 1) Pre-heat treatment: Put it into a heating furnace and heat it at a temperature of 300°C;

[0073] 2) Surface cleaning: Use a manual welding torch to clean the surface of the press roll obtained by the above step 1) preheating to remove the rust on the surface of the roll and the moisture and sludge that infiltrate the inner tissue of the roll;

[0074] 3) Turning removal: lathe turning to remove the fatigue layer of the roller surface layer;

[0075] 4) Measurement: Measure the worn squeeze roller to obtain the amount of wear and confirm the welding thickness;

[0076] 5) Welding repair: Welding repairs on the worn press rolls by using a welding machine on a lathe, leaving a machining allowance of 2-5mm for the r...

Embodiment 3

[0088] See attached Figure 1~8 As shown, the sugarcane squeezing roller repair process of the present invention is realized by the following scheme:

[0089] The process steps of the sugarcane squeezing roller repair process of the present invention are as follows:

[0090] 1) Pre-heat treatment: Put it in a heating furnace and heat it at a temperature of 100~300°C;

[0091] 2) Surface cleaning: Use a manual welding torch to clean the surface of the press roll obtained by the above step 1) preheating to remove the rust on the surface of the roll and the moisture and sludge that infiltrate the inner tissue of the roll;

[0092] 3) Turning removal: lathe turning to remove the fatigue layer of the roller surface layer;

[0093] 4) Measurement: Measure the worn squeeze roller to obtain the amount of wear and confirm the welding thickness;

[0094] 5) Welding repair: Welding repairs on the worn press rolls by using a welding machine on a lathe, leaving a machining allowance of 2-5mm for the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com