Ice cream and preparation technology thereof

An ice cream and emulsifier technology, applied in the fields of frozen desserts, food science, sugary food ingredients, etc., can solve the problems of increased blood sugar concentration, human damage, affecting the taste and appearance of ice cream, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

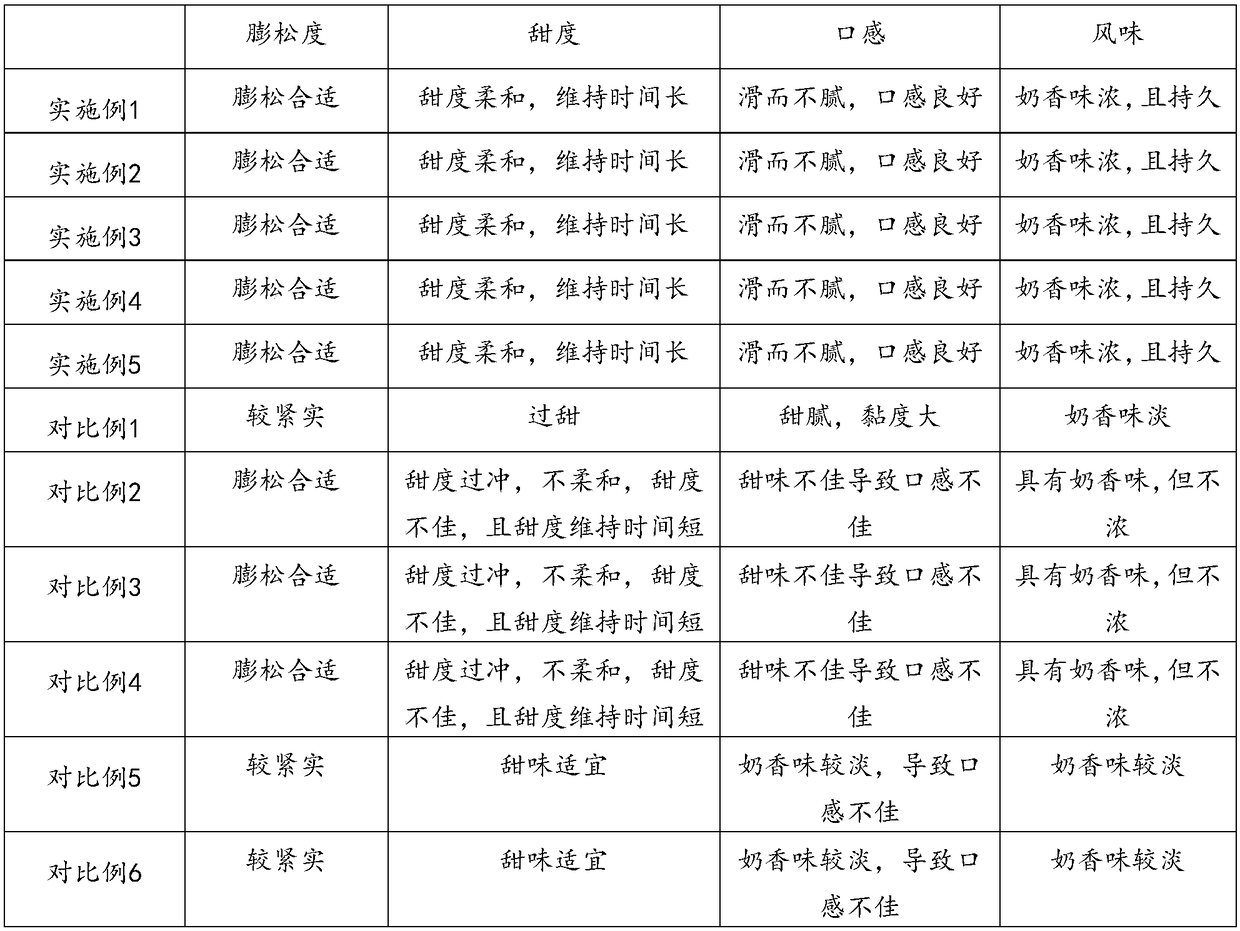

Examples

preparation example Construction

[0045] The present invention also provides a kind of preparation method of ice cream, described method comprises steps:

[0046] (1) Mixing of raw materials: add sucrose, fructose, L-arabinose, xylan, trehalose, emulsifier and stabilizer to water at 60-80°C, after mixing, lower the temperature to 40-50°C, add milk powder and cream , vegetable fat, mixed to obtain a mixture;

[0047] (2) Sterilization: heat the obtained mixture at 75-85° C. for 20-40 minutes, and carry out pasteurization;

[0048] (3) Homogenization: adopt the two-stage homogeneous method, the first-stage homogeneous pressure is maintained at 8-15Mpa for 5-8min; the second-stage homogeneous pressure is maintained at 2-6Mpa for 6-10min, and the homogeneous temperature is maintained at 50 60°C;

[0049] (4) Aging: Cool the homogenized material to 0-5°C and age for 8-16 hours;

[0050] (5) Freezing: stirring at -8 to -5°C;

[0051] (6) Hardening: placing the material obtained in step (5) at -25 to -15° C. for ...

Embodiment 1

[0058] ice cream recipe

[0059] 2kg milk powder, 0.5kg butter, vegetable fat (0.25kg palm oil and 0.25kg peanut oil), 0.6kg white granulated sugar, 0.5kg fructose, 0.08kg L-arabinose, 0.15kg xylan, 0.1kg trehalose, emulsifier ( 0.08 kg glyceryl monostearate, 0.1 kg lecithin and 0.12 kg polysorbate-80), stabilizer (0.1 kg sodium alginate) and 5.17 kg water.

[0060] How to prepare ice cream

[0061] (1) Raw material mixing:

[0062] Mix white sugar, fructose, L-arabinose, xylan, trehalose, emulsifier and stabilizer, add to 70°C water, stir and mix for 10min, then lower the temperature to 45°C, add milk powder, cream and vegetable Fat, stirred and mixed for 15 minutes to obtain a mixture;

[0063] (2) Sterilization:

[0064] The obtained mixture was incubated at 80° C. for 30 minutes, and then pasteurized;

[0065] (3) homogeneous:

[0066] Using the two-stage homogenization method, the first-stage homogeneous pressure was maintained at 12Mpa for 6 minutes; the second-sta...

Embodiment 2

[0074] ice cream recipe

[0075] 2kg milk powder, 0.5kg cream, vegetable fat (0.25kg palm oil and 0.25kg peanut oil), 0.6kg white granulated sugar, 0.5kg fructose, 0.06kg L-arabinose, 0.1kg xylan, 0.08kg trehalose, emulsifier ( 0.08 kg glyceryl monostearate, 0.1 kg lecithin and 0.12 kg polysorbate-80), stabilizer (0.1 kg sodium alginate) and 5.26 kg water.

[0076] How to prepare ice cream

[0077] The preparation method of the ice cream of embodiment 2 is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com