Primary throttling inter complete cooling refrigeration system with medium temperature evaporators

A refrigeration system and evaporator technology, which is applied in the direction of reversible cycle compressors, refrigerators, refrigeration components, etc., can solve the problems of single refrigeration temperature in cold storage, damage to compressors, and reduced defrosting efficiency, so as to help protect compressors , prolong the service life, and have the effect of sufficient heat supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

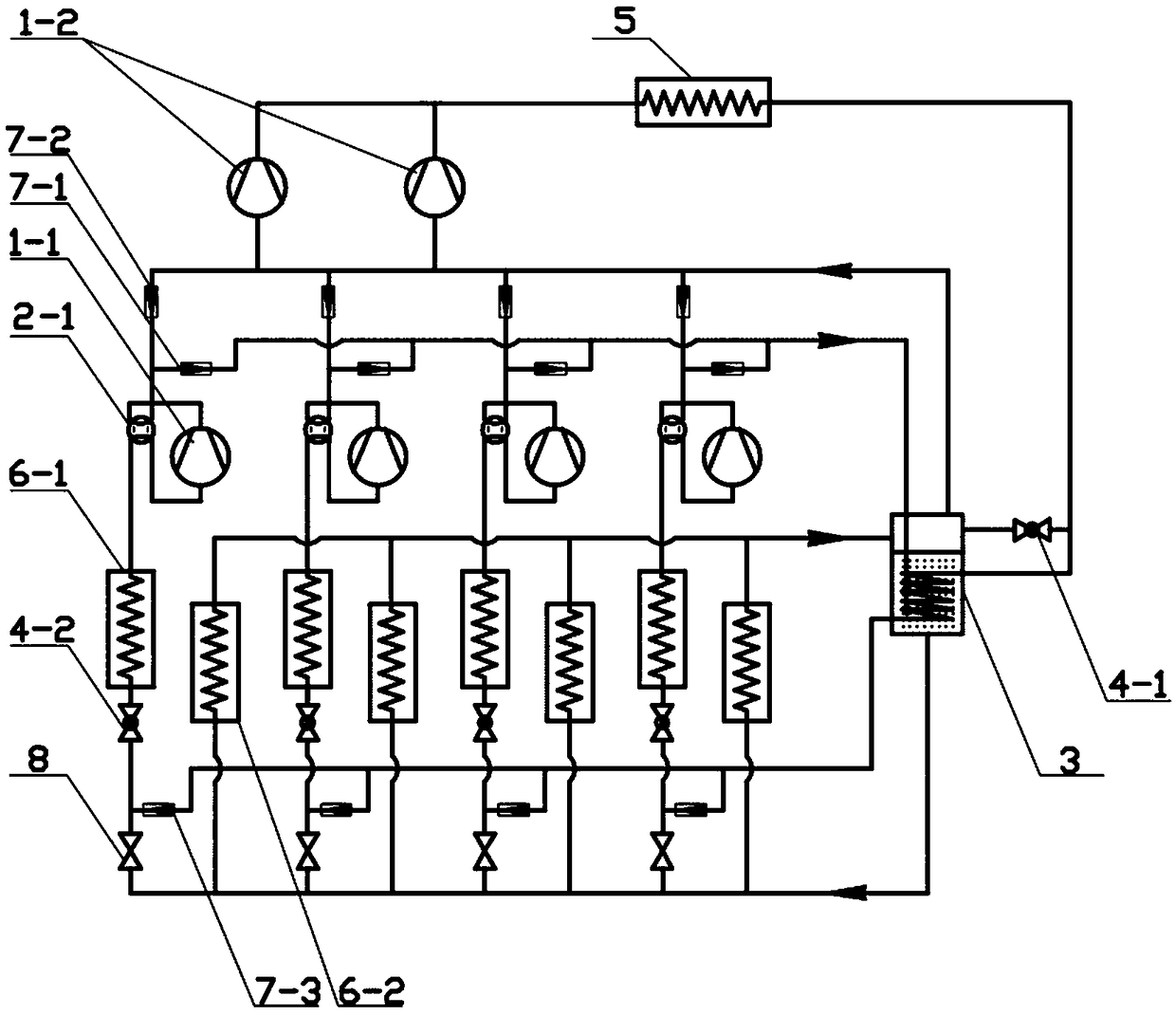

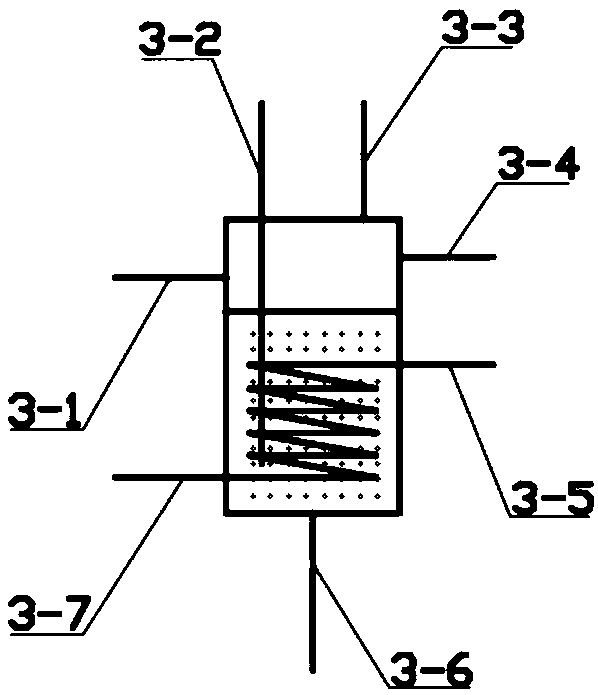

[0029] The structure and principle diagram of the cooling system with primary throttling and complete cooling in the middle of hot gas defrosting in the present invention is as follows figure 1 As shown, it includes a high-pressure stage compressor unit, a condenser 5, a first throttle valve 4-1, an intercooler 3 and multiple low-pressure stage units. The high-pressure stage compressor unit described in this embodiment includes one or more high-pressure stage compressors 1-2. When multiple high-pressure stage compressors are used, the suction ports of each of the high-pressure stage compressors 1-2 are connected in parallel. As the suction end of the high-pressure stage compressor unit, the exhaust ports of each of the high-pressure stage compressors 1-2 are connected in parallel as the exhaust end of the high-pressure stage compressor unit. Each of the low-pressure units includes a low-pressure stage compressor 1-1, a first four-way reversing valve 2-1, a second throttle valv...

Embodiment 2

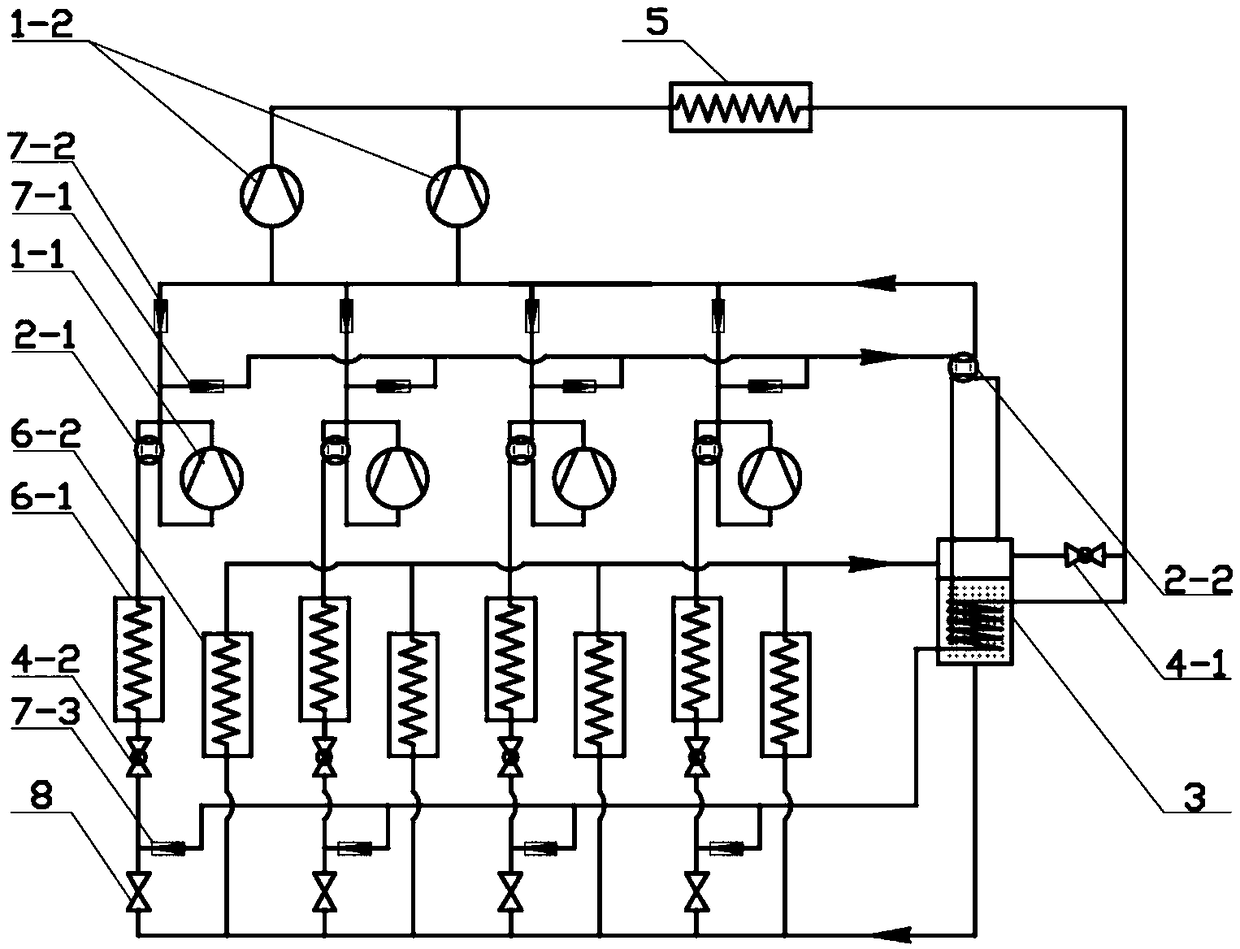

[0033] The structural principle diagram of the refrigeration system with a throttling and intermediate complete cooling for high-temperature hot gas defrosting in the present invention is as follows figure 2As shown, it includes a high-pressure stage compressor unit, a condenser 5, a first throttle valve 4-1, a second four-way reversing valve 2-2, an intercooler 3 and multiple low-pressure stage units. Wherein, the high-pressure stage compressor unit includes one or more high-pressure stage compressors 1-2, when multiple high-pressure stage compressors are used, the suction ports of each of the high-pressure stage compressors 1-2 are connected in parallel as the The suction end of the high-pressure stage compressor unit, the exhaust port of each of the high-pressure stage compressors 1-2 is connected in parallel as the exhaust end of the high-pressure stage compressor unit. Each of the low-pressure stage units includes a low-pressure stage compressor 1-1, a first four-way rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com