Preparation method of epoxy resin composite material based on quadruple hydrogen bond supermolecular self repairing

A technology of epoxy resin and composite materials, which is applied in the field of preparation of functional materials, can solve problems such as poor mechanical properties, long repair time, and low repair efficiency, and achieve the effects of simple preparation, high conversion rate, and controllable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

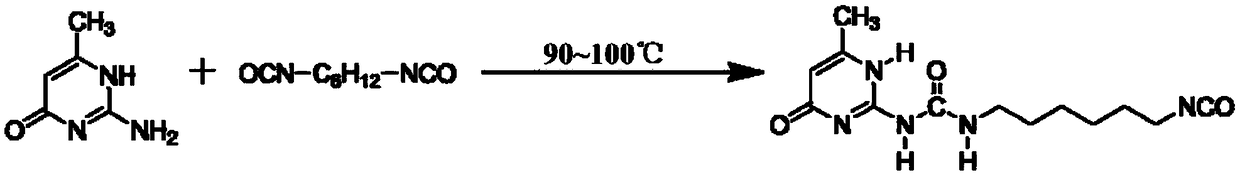

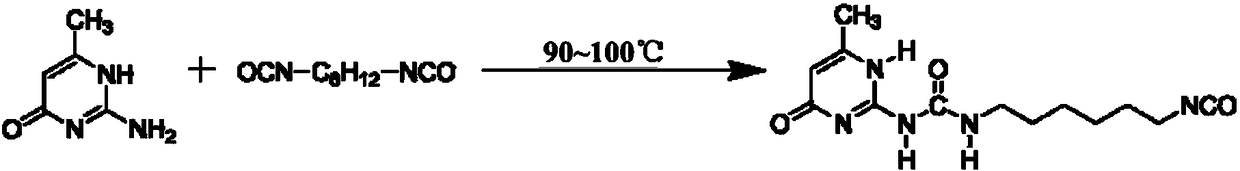

[0030] (1) Synthon preparation

[0031] Weigh 2-amino-4-hydroxy 6-methylpyrimidine and hexamethylene diisocyanate with a mass ratio of 1:10, heat up to 90°C under the protection of dry nitrogen, and react with electromagnetic stirring for 26 hours. After the reaction is completed, cool down to room temperature , add water-removing n-hexane, precipitate, suction filter, and wash until the filtrate is verified by infrared spectroscopy to be free of hexamethylene diisocyanate, and the white powder obtained is a synthon, which is stored in a liquid seal with n-hexane.

[0032] (2) Preparation of supramolecular chloroform solution

[0033] The synthon that step (1) obtains and polyether amine D2000 are with molar ratio n (-NCO) :n (-NH2) = After mixing at a ratio of 1:1, add an appropriate amount of chloroform, and add a little catalyst di-n-butyltin dilaurate. Under the condition of dry nitrogen protection, heat up to 65°C, electromagnetically stir and reflux until the infrared ...

specific Embodiment approach 2

[0037] (1) Synthon preparation

[0038] Weigh 2-amino-4-hydroxy 6-methylpyrimidine and hexamethylene diisocyanate with a mass ratio of 1:10, heat up to 90°C under the protection of dry nitrogen, and react with electromagnetic stirring for 26 hours. After the reaction is completed, cool down to room temperature , add water-removing n-hexane, precipitate, suction filter, and wash until the filtrate is verified by infrared spectroscopy to be free of hexamethylene diisocyanate, and the white powder obtained is a synthon, which is stored in a liquid seal with n-hexane.

[0039] (2) Preparation of supramolecular chloroform solution

[0040] The neutral synthon that step (1) obtains and polyether alcohol 2120 are n in molar ratio (-NCO) :n (-OH) = After mixing at a ratio of 1:1, add an appropriate amount of chloroform, and add a little catalyst di-n-butyltin dilaurate. Under the condition of dry nitrogen protection, heat up to 65°C, electromagnetically stir and reflux until the inf...

specific Embodiment approach 3

[0044] (1) Synthon preparation

[0045] Weigh 2-amino-4-hydroxy 6-methylpyrimidine and hexamethylene diisocyanate with a mass ratio of 1:10, heat up to 90°C under the protection of dry nitrogen, and react with electromagnetic stirring for 26 hours. After the reaction is completed, cool down to room temperature , add water-removing n-hexane, precipitate, suction filter, and wash until the filtrate is verified by infrared spectroscopy to be free of hexamethylene diisocyanate, and the white powder obtained is a synthon, which is stored in a liquid seal with n-hexane.

[0046] (2) Preparation of supramolecular chloroform solution

[0047] The synthon that step (1) obtains and hydroxyl-terminated polybutadiene HTPB are n in molar ratio (-NCO) :n (-OH) = After mixing at a ratio of 1:1, add an appropriate amount of chloroform, and add a little catalyst di-n-butyltin dilaurate. Under the condition of dry nitrogen protection, heat up to 65°C, electromagnetically stir and reflux until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com