Preparation method of microporous polyethylene mildew-proof preservative film

A technology of microporous polyethylene and plastic wrap, applied in the field of environmental protection materials, can solve the problems of poor air permeability and moisture permeability, poor stability of microporous polyethylene film, etc., achieve high air permeability, reduce carbon dioxide damage, and improve moisture resistance performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

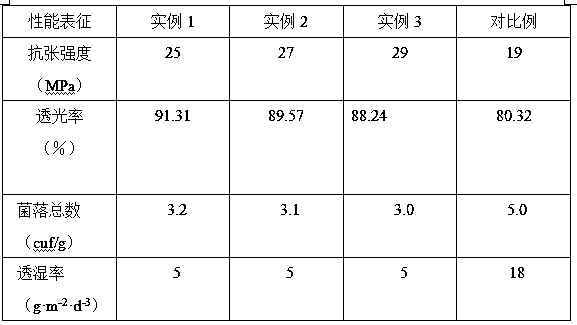

Examples

Embodiment Construction

[0016] Use 0.2mol / L acetic acid solution to prepare chitosan-acetic acid solution with a mass fraction of 0.5% to 0.7%; weigh 20 to 30 parts of chitosan-acetic acid solution and 10 to 15 parts of 0.05mol / L silver nitrate solution, 3~5 parts of 0.2mol / L sodium borohydride solution, 5~10 parts of nano-TiO 2 , 5-10 parts of nano-SiO 2 , add silver nitrate solution to the chitosan-acetic acid solution, stir magnetically for 15-20 minutes, add sodium borohydride solution at a speed of 800r / min, the solution is light yellow at this time, stop stirring after 1h, add nano-TiO 2 and nano-SiO 2 and stir evenly to obtain composite nanomaterials; in parts by weight, respectively weigh 40 to 50 parts of PVA solution, 1 to 3 parts of composite nanomaterials, 1 to 2 parts of borax solution, and 3 to 5 parts of ammonium carbonate. Add composite nanomaterials and ammonium carbonate into the solution, stir magnetically for 15-20 minutes, and then ultrasonically sound for 10-15 minutes to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com