Recycling method for electrode foil-corrosion waste nitric acid

An electrode foil and waste nitric acid technology, which is applied in the directions of nitric acid, aluminum nitrate, nitrogen oxides/oxyacids, etc., can solve the problems of inability to treat printing and dyeing wastewater, high input of raw materials, and danger of waste acid, and achieve low treatment costs. , The effect of high reaction temperature and high operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

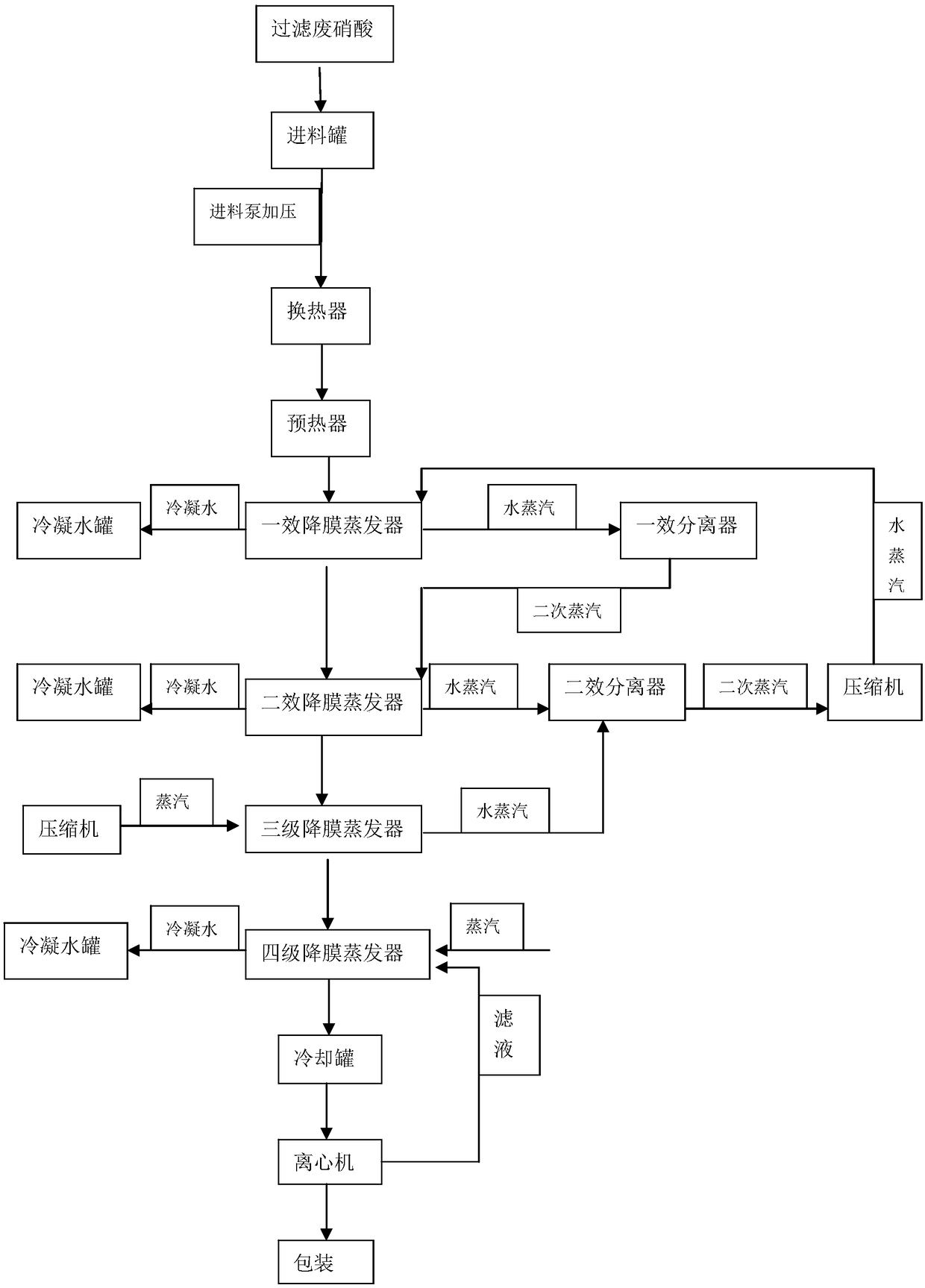

[0030] (1) Preheating: Send the filtered electrode foil waste acid to the feed tank, pressurized by the feed pump, enter the heat exchanger to preheat to about 63°C, and then heat to 82°C through the preheater , into the first-effect falling film evaporator; among them, the steam in the shell side of the first-effect and third-stage falling-film evaporators is mixed with non-condensable gas as the preheating heat source;

[0031] (2), evaporation:

[0032] One-effect evaporation: pump the waste acid preheated in step (1) into the first-effect falling-film evaporator, the raw material in the tube of the first-effect falling-film evaporator exchanges heat with the heating steam outside the tube to make the raw material boil and evaporate, and the raw material is concentrated The pressure difference enters the two-effect falling film evaporator;

[0033] Among them, the water vapor generated by the evaporation of the second-effect falling film evaporator and the third-stage fall...

Embodiment 2

[0048] (1) Preheating: Send the filtered electrode foil waste acid to the feed tank, pressurized by the feed pump, enter the heat exchanger to preheat to 60°C, and then heat to 85°C through the preheater. After entering the first-effect falling film evaporator; among them, the steam in the shell side of the first-effect and third-stage falling-film evaporators is mixed with non-condensable gas as a preheating heat source;

[0049] (2), evaporation:

[0050] One-effect evaporation: pump the waste acid preheated in step (1) into the first-effect falling-film evaporator, the raw material in the tube of the first-effect falling-film evaporator exchanges heat with the heating steam outside the tube to make the raw material boil and evaporate, and the raw material is concentrated The pressure difference enters the two-effect falling film evaporator;

[0051] Among them, the water vapor generated by the evaporation of the second-effect falling film evaporator and the third-stage fal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com