Nano cellulose-reinforced composite photocatalyst as well as preparation method and application thereof

A nanocellulose and photocatalyst technology, applied in the field of material chemistry, can solve the problems of complex catalyst preparation process, difficult to achieve synergistic promotion, and limited modification effect, so as to promote catalytic degradation efficiency, excellent degradation performance, and increase activity site effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of nanocellulose reinforced composite photocatalyst of the present invention, comprising the following steps:

[0044] (1) Get 20g TEMPO oxidized nanocellulose suspension (CNFs, the solid content of cellulose nanofibrils is 0.01wt%, the aspect ratio of nanofibers is about 300-600) and 0.04g silver nitrate, stir and fully dissolve;

[0045] (2) Get 20g of urea and dissolve it in the above-mentioned mixed solution, fully stir and dissolve;

[0046] (3) Place the mixed solution obtained in step (2) in a blast drying oven, and dry at 70° C. for 12 hours to obtain a precursor substance;

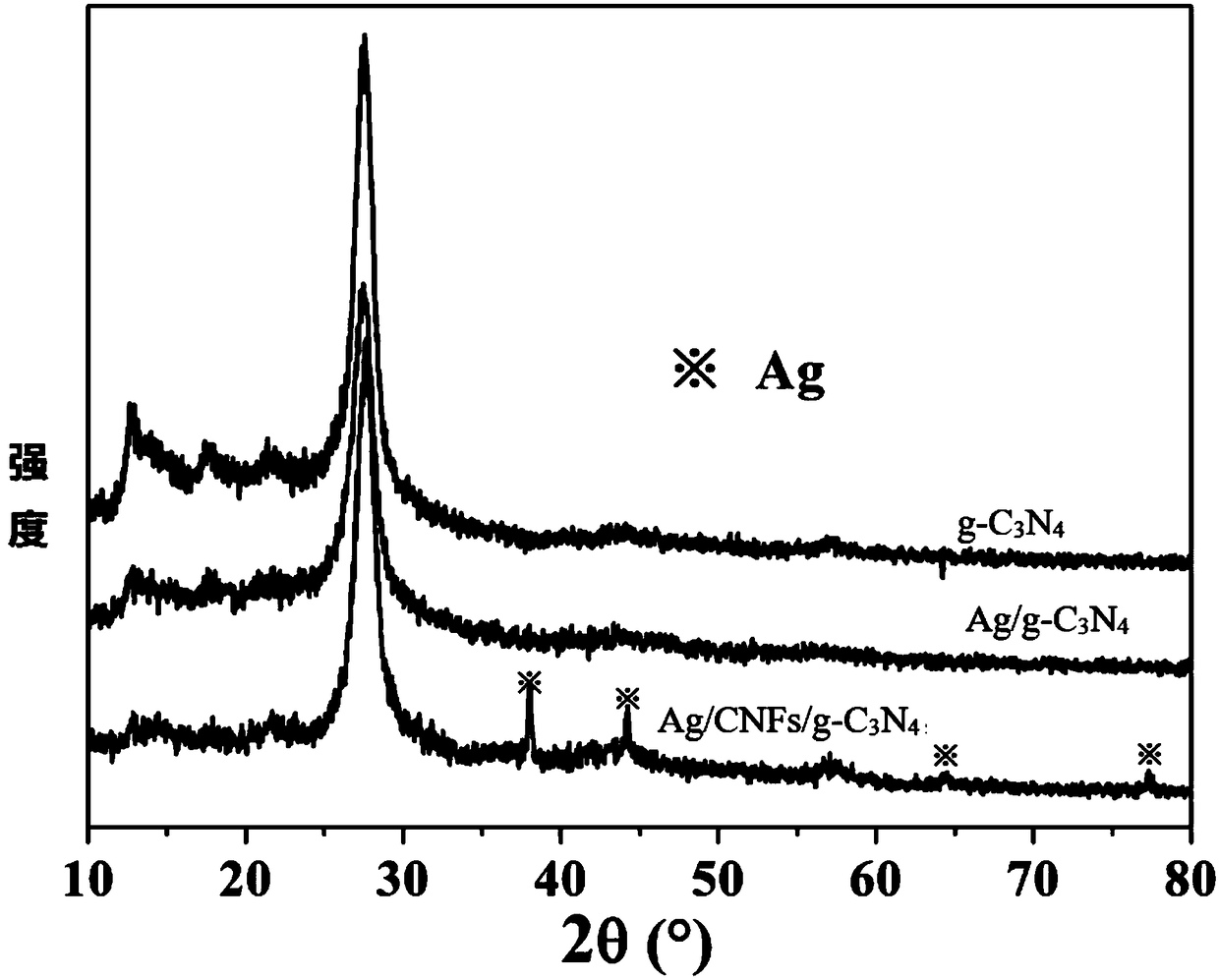

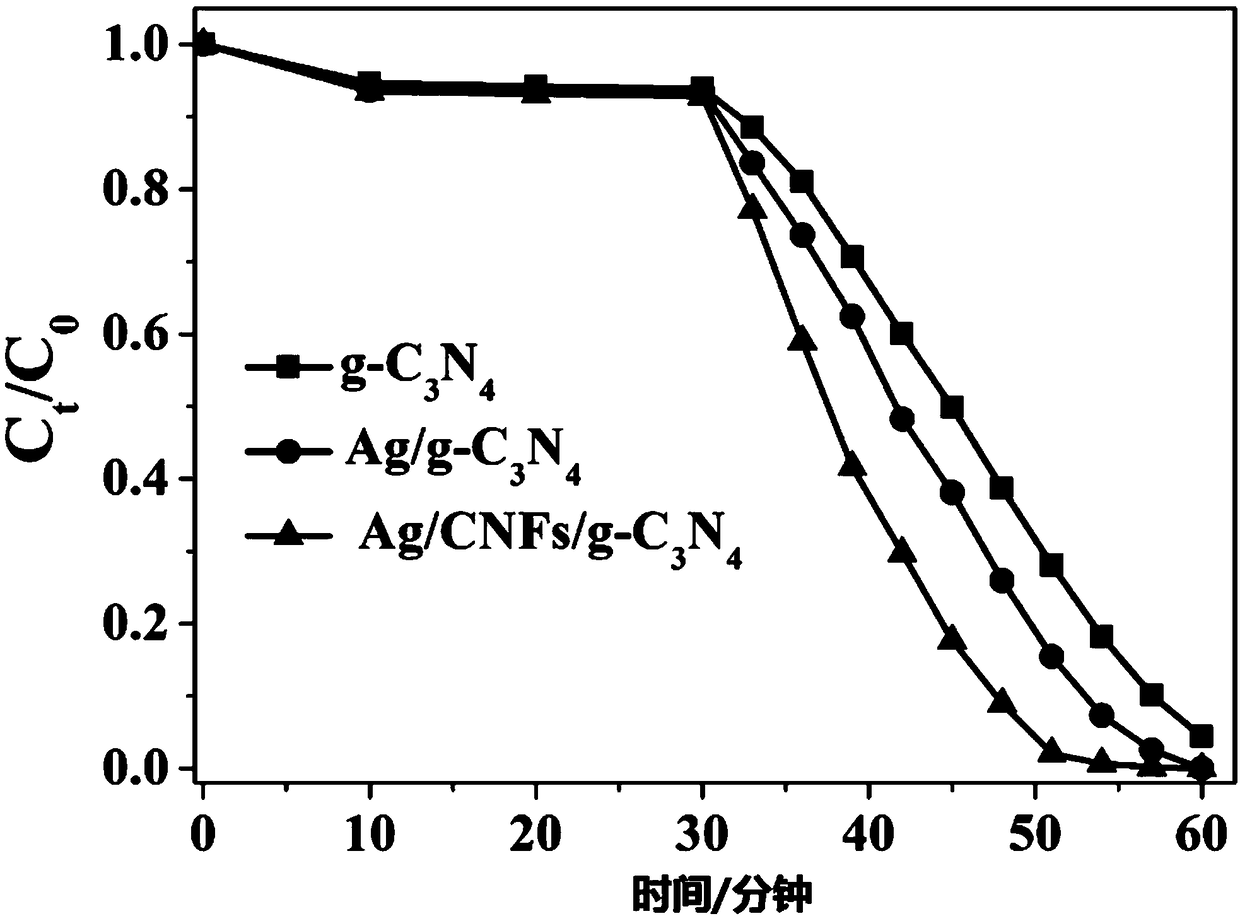

[0047] (4) Cover the crucible containing the precursor material with a lid, wrap a layer of tinfoil and place it in a muffle furnace. Calcinate at 550°C for 4 hours in an air atmosphere with a heating rate of 15°C / min. After natural cooling, Nanocellulose-reinforced composite photocatalyst Ag / CNFs / g-C can be obtained 3 N 4 , its XRD pattern and SEM photo are as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com