Preparation method for easy-suturing high-simulation tissue engineering neural repair scaffold

A technology for simulating tissue and nerve repair, applied in the field of nerve repair tissue engineering, can solve the problems of porous scaffolds with flat ends that are not easy to be sutured, easy to collapse, and lack of internal three-dimensional structure, so as to guide nerve tissue regeneration, relieve pain, and solve problems such as lack of The effect of the internal three-dimensional structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

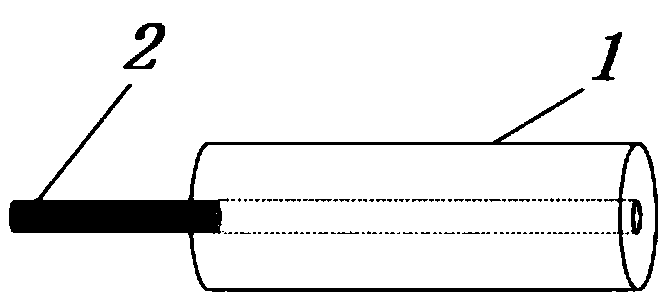

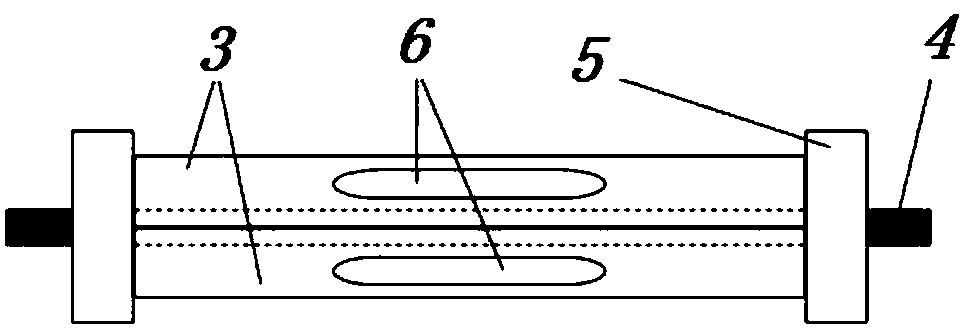

[0027] The easy-to-suture highly simulated tissue engineering nerve repair scaffold and the preparation method thereof of the present invention include the steps of preparing a suspension, preparing an inner core of an array microtube, preparing a collagen skin, and cutting and assembling. in,

[0028] The step of preparing the suspension comprises: taking collagen and chitosan, mixing them and dissolving them in acetic acid solution to obtain a collagen-chitosan suspension; in this step, the collagen and chitosan The weight ratio between them is 1:0~5; the mass concentration of the acetic acid solution is 3~8mg / mL, and the weight ratio of the weight sum of collagen and chitosan to the acetic acid solution is 1~10:200. After dissolving collagen and chitosan raw materials in acetic acid solution, use a homogenizer to intermittently stir in an ice-water bath, and the stirring speed is controlled at 2500-3500rpm; after mixing, use a centrifuge to centrifuge at 10,000rpm for 30min...

Embodiment 1

[0036] A method for preparing an easy-to-suture highly simulated tissue engineered nerve repair scaffold, which is carried out according to the following steps:

[0037] (1) Suspension preparation: Weigh 200 mg of collagen and dissolve it in 4 g of acetic acid solution with a mass concentration of 6 mg / mL, stir intermittently in an ice-water bath with a homogenizer, control the stirring speed at 2500-3500 rpm, and mix thoroughly. After uniformity, use a centrifuge to centrifuge at a speed of 10000rpm for 30min to remove air bubbles;

[0038] (2) Preparation of array microtube inner core: inject the suspension after removing air bubbles into one end of the inner core mold, prevent the generation of air bubbles during the injection process, and then plug the injection end of the inner core mold to match the inner diameter of the inner mold shell. The temperature-conducting rod, and then connect multiple injected inner core molds to the uniform falling device; with 2×10 -5 Immer...

Embodiment 2

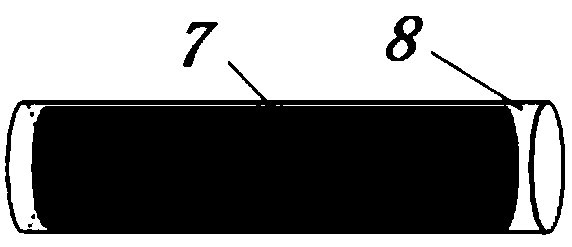

[0042] The difference with Example 1 is: when the suspension is prepared, take 280mg collagen and 70mg chitosan, mix and dissolve in 28g acetic acid solution of 5mg / mL and stir for processing; when the array microtube inner core is prepared, 1×10 after injection molding -6 Gradient cold showering at a speed of m / s, and then immerse the lyophilized array microtube inner core in 1% genipin solution for cross-linking for 12 hours; when preparing the scaffold skin, immerse it in distilled water with a pH of 8 after injection molding, After drying, soak in 1% genipin and cross-link for 24 hours; when preparing the easy-to-suture highly simulated tissue engineered nerve scaffold, insert the scaffold inner core 7 into the scaffold outer skin 8 and leave a 3 mm outer skin length at both ends.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com