Rock mass permeability in-situ test device

An in-situ test and permeability technology, which is applied in the direction of measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of device blockage observation process, equipment failure, and gas supply pipelines that are easy to break And other problems, to achieve the effect of sensitive and balanced pressure regulation, easy reset, and reduce the number of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with specific embodiments.

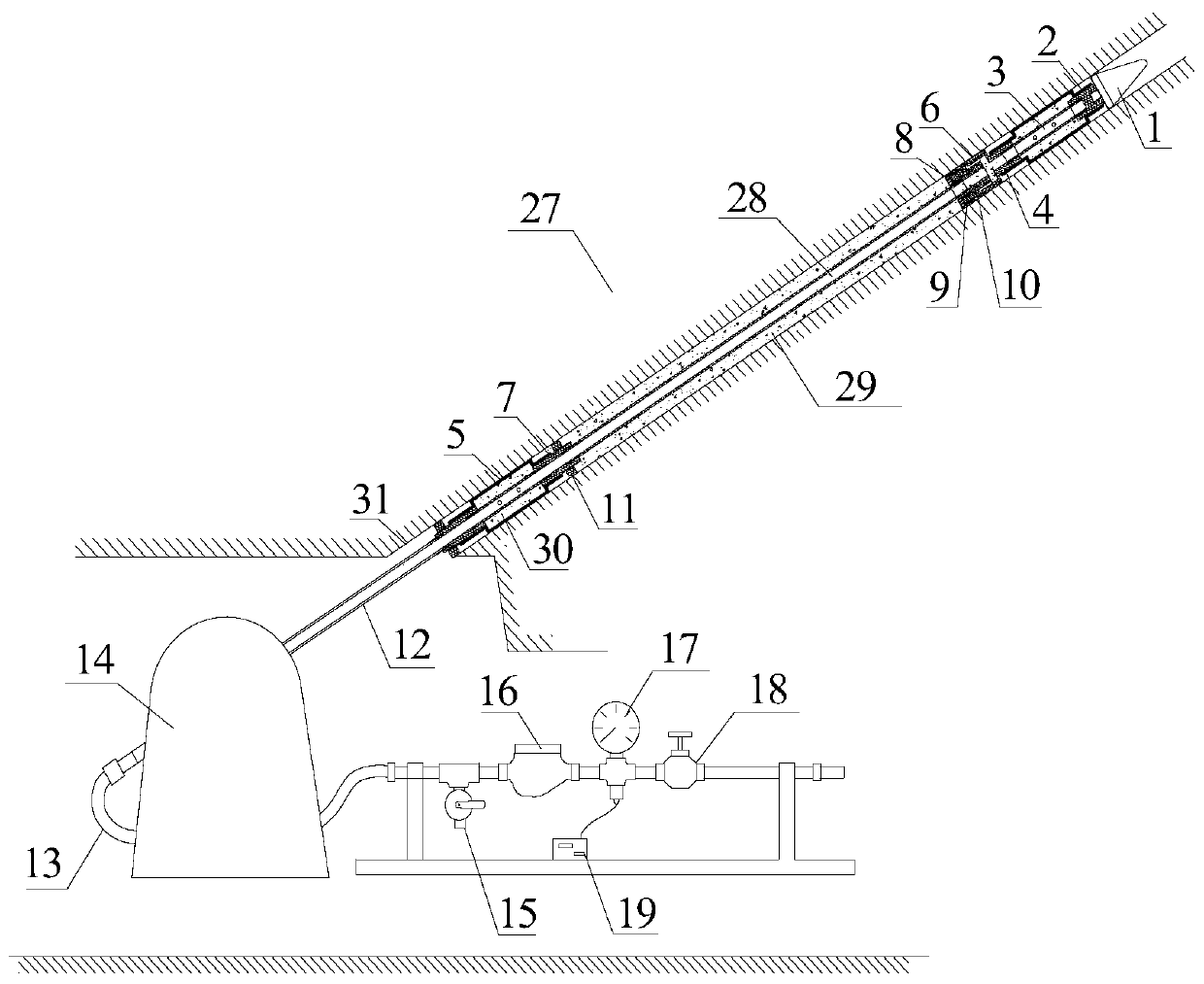

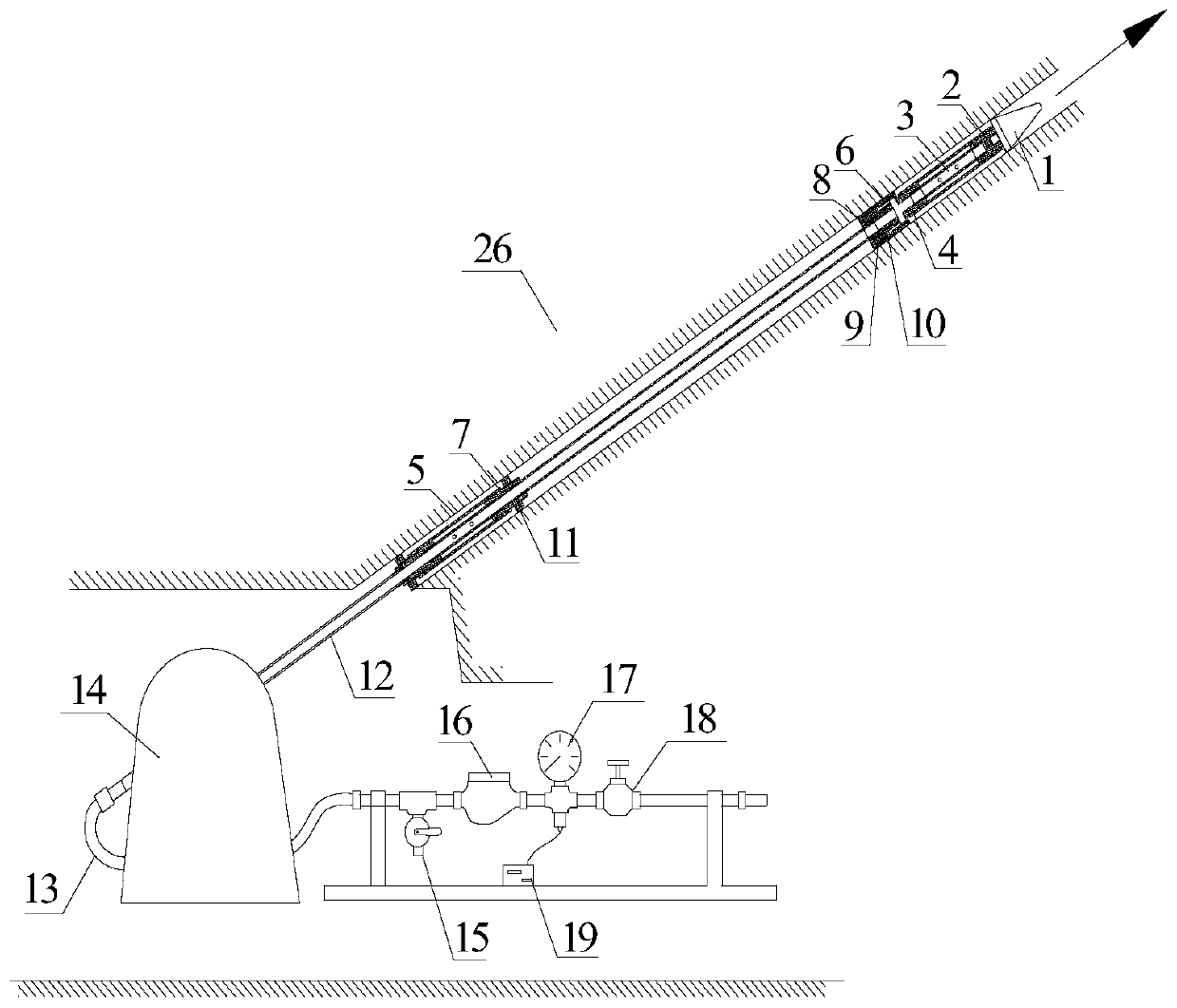

[0045] An in-situ test device for rock mass permeability, which mainly includes a test probe, a propulsion mechanism, and a control mechanism;

[0046] Such as Figure 1-3 As shown, the test probe includes a rubber bag 5, a leaking pipe 3, a converter 6, and a connecting pipe 28. The two ends of the leaking pipe 3 are respectively connected to joint one 2, joint two 4 or joint three 7. The periphery of the leaking water pipe 3 between the joints is surrounded by a rubber bag 5, and a certain plugging cavity 30 is formed between the rubber bag 5 and the leaking water pipe 3. The inside of the converter 6 is provided with a conical conversion body 10, and the inside and surface of the conical conversion body 10 are respectively provided with a water hole 23 and an annular water tank 22, forming a water leakage channel with the first hole 20 on the converter 6.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com