High-strength multi-element zinc base alloy coated steel wire for bridge cable, and hot-dipping technology thereof

An alloy coating, high-strength technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problem that the anti-corrosion life cannot meet the relevant requirements, and achieve good salt spray corrosion resistance and high strength , good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

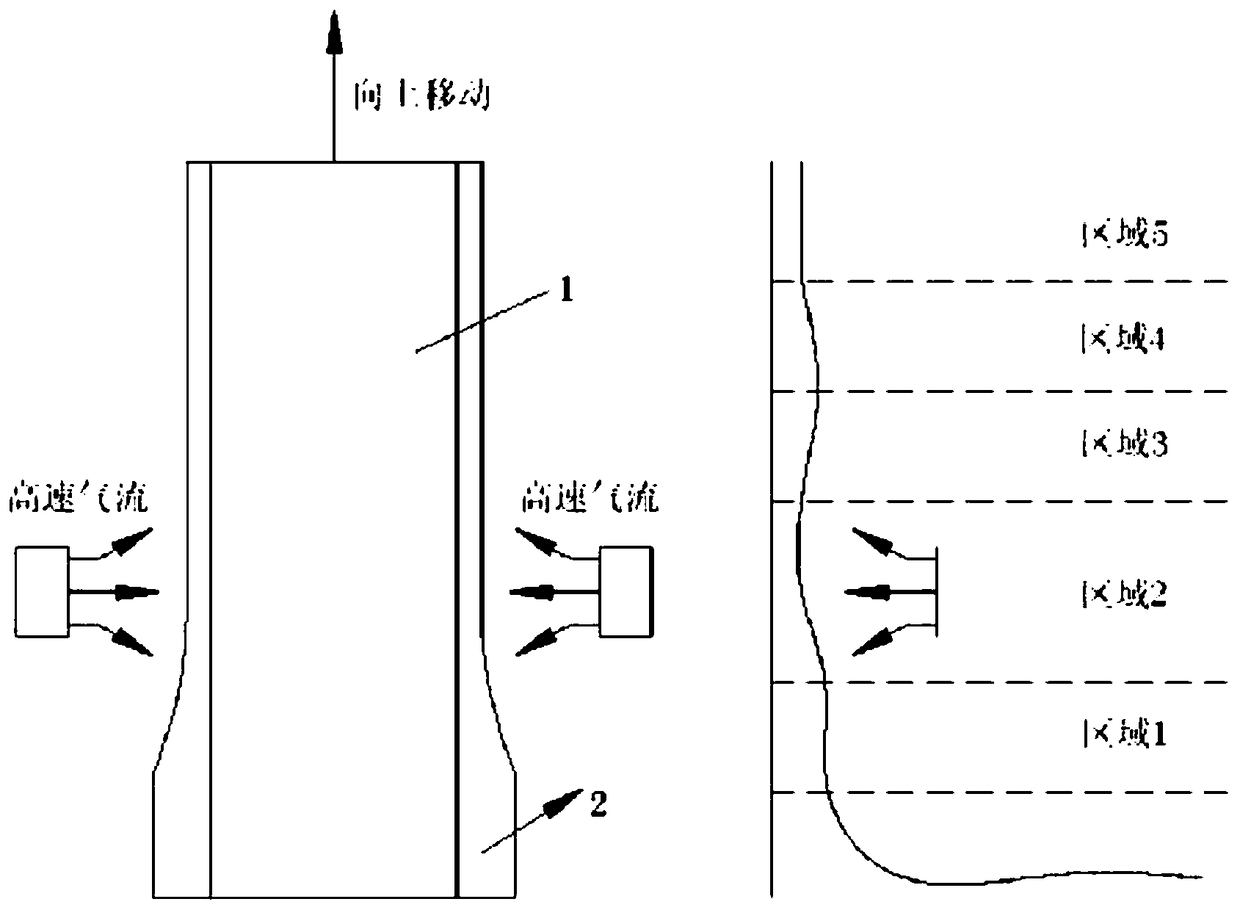

[0039] A hot-dip process for high-strength multi-component zinc-based alloy-coated steel wire for bridge cables, the process: (sodium hydroxide + sodium carbonate + sodium phosphate) compound alkaline solution alkaline cleaning to remove oil → lead bath → water rinse → hydrochloric acid + corrosion inhibitor (Sulfuric acid) compound pickling and derusting → rinse with water → (ammonium chloride + zinc chloride) plating aid → drying → rapid hot-dip zinc-based alloy melt (trace alloys such as aluminum, nickel and rare earth elements, etc.) → nitrogen + electromagnetic Composite wiping to remove zinc → cooling → hot-dip galvanized aluminum alloy melt (aluminum content 9%-12%)—nitrogen wiping—cooling—take-up.

[0040] The specific process is

[0041] Alkali cleaning: the lye prepared by sodium hydroxide and alkaline salt is used to emulsify, soften and dissolve the oily impurities on the surface of the smooth steel wire. The alkaline salt is selected from sodium carbonate + sodium...

Embodiment 2

[0052] A hot-dip process for high-strength multi-element zinc-based alloy coated steel wire for bridge cables, process flow: see Example 1.

[0053] The specific process is

[0054] Alkali cleaning, lead bath, pickling, and plating aid are all referring to embodiment 1;

[0055] Hot-dip zinc-based micro-alloy melt: quickly immerse the steel wire treated with the flux into the zinc-based micro-alloy melt pool containing trace alloys, the main chemical composition is Zn-Al-Ni; the content of Al is 0.02wt% , the content of Ni is 0.25wt%;

[0056] Electromagnetic wiping + nitrogen wiping to remove zinc: see Example 1;

[0057] Hot-dip Zn-Al multi-element alloy: quickly immerse the wiped steel wire into the zinc-aluminum-based microalloy melt pool containing trace alloys, the main chemical composition is Zn-Al multi-element alloy melt, and the Al content in the melt is 12%, the content of La is 0.02wt%, the content of Mg is 0.2wt%;

[0058] Nitrogen swab: See Example 1.

[005...

Embodiment 3

[0062] A hot-dip process for high-strength multi-element zinc-based alloy coated steel wire for bridge cables, process flow: see Example 1.

[0063] The specific process is

[0064] Alkali cleaning, lead bath, pickling, and plating aid are all referring to embodiment 1;

[0065] Hot-dip zinc-based microalloy melt: quickly immerse the steel wire treated with plating flux into the zinc-based microalloy melt pool containing trace alloys, the main chemical composition is Zn-Al-Ni; the content of Al is 0.01wt% , the content of Ni is 0.18wt%;

[0066] Electromagnetic wiping + nitrogen wiping to remove zinc: see Example 1;

[0067] Hot-dip Zn-Al multi-element alloy: quickly immerse the wiped steel wire into the zinc-aluminum-based microalloy melt pool containing trace alloys, the main chemical composition is Zn-Al multi-element alloy melt, and the Al content in the melt is 10%, the content of Cs is 0.05wt%;

[0068] Nitrogen swab: See Example 1.

[0069] The addition of Al and N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com