A metal leaching recovery method for continuous multi-stage extraction

A recovery method and extraction technology, applied in the field of environmental chemistry and environmental engineering, can solve problems such as difficult separation, poor quality of recovered products, difficult monomer dissociation, etc., and achieve the effect of low operation cost, low cost, and easy-to-obtain products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

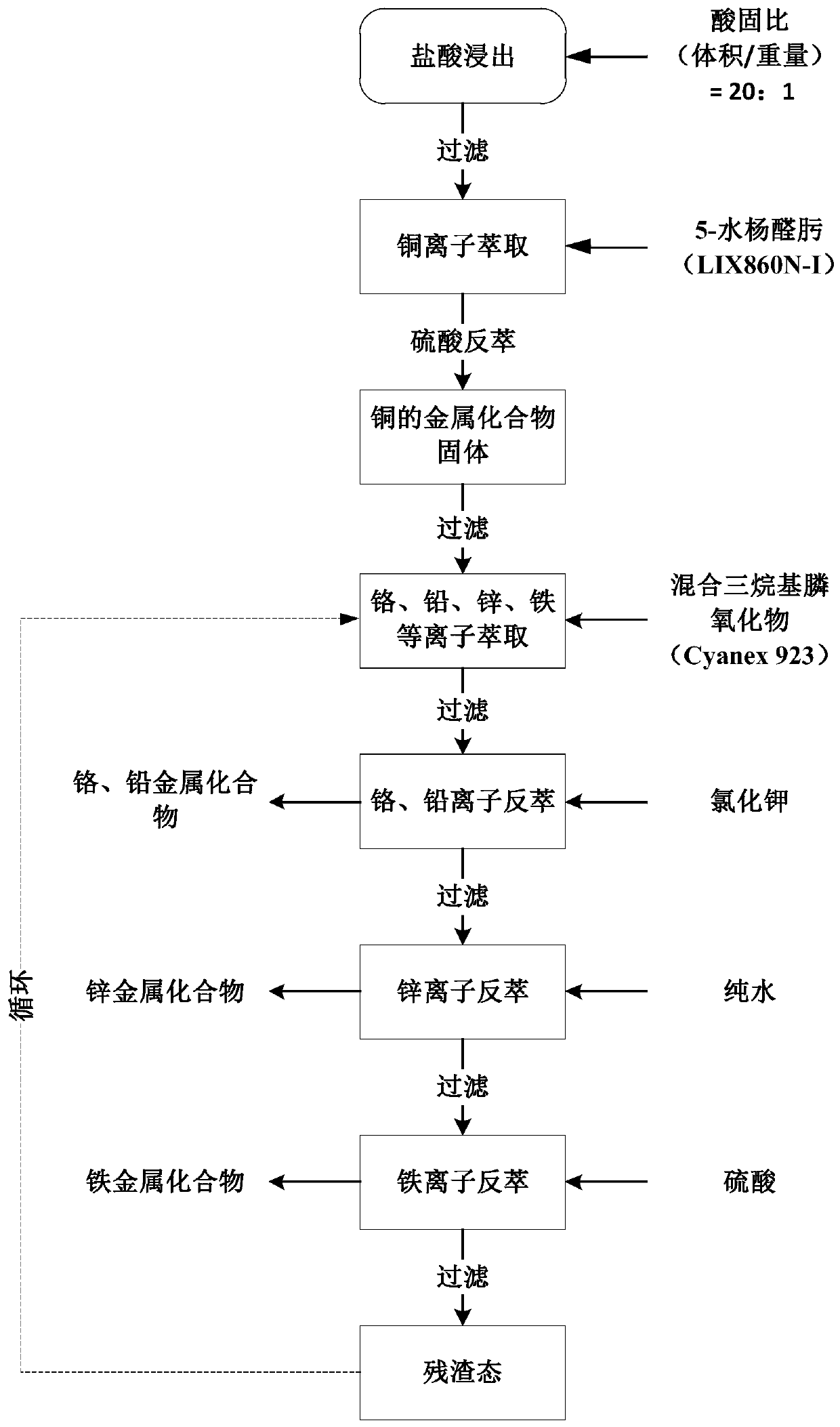

[0046] The metal leaching recovery method of the continuous multistage extraction of the present embodiment comprises the following steps:

[0047] 1) Weigh the fly ash that has been dried to constant weight and disperse it in water according to the liquid-solid ratio (volume / mass) of 5:1, use 5mol / L hydrochloric acid to adjust the pH of the leaching solution to 2, stir and leaching at a speed of 200rpm and 20°C 20h, filter and keep the supernatant;

[0048] 2) Utilize 0.01mol / L 5-salicylaldoxime (LIX860N-I) prepared in kerosene according to the condition that the organic phase: water ratio (volume / volume) is 1:2, carry out two repeated extractions to the filtrate obtained in step 1, Extract at 20°C for 6 minutes to reach extraction equilibrium, then stand and separate to obtain the extract phase and raffinate phase;

[0049] (3) Use 5mol / L sulfuric acid back extraction step 2 gained organic phase extraction liquid, after back extraction equilibrium, leave standstill to separ...

Embodiment 2

[0055] The metal leaching recovery method of the continuous multistage extraction of the present embodiment comprises the following steps:

[0056] (1) Weigh the fly ash dried to constant weight and disperse it in water according to the liquid-solid ratio (volume / mass) of 20:1, use 3mol / L hydrochloric acid to adjust the pH of the leachate to 2, and stir at a speed of 200rpm and 20°C Mix and extract for 20 hours, filter and keep the supernatant;

[0057] (2) Utilize 0.01mol / L 5-salicylaldoxime (LIX860N-I) prepared in kerosene to carry out two repeated extractions to the filtrate obtained in step 1 under the condition that the volume ratio of organic phase: aqueous phase is 1:2. Extract at 20°C for 3 minutes to reach extraction equilibrium and then stand for separation;

[0058] (3) Use 5mol / L sulfuric acid back extraction step 2 gained organic phase extraction liquid, after back extraction equilibrium, leave standstill to separate, the organic phase raffinate can be recycled i...

Embodiment 3

[0064] This embodiment discloses a metal leaching recovery method for continuous multi-stage extraction, comprising the following steps:

[0065] (1) Weigh the fly ash dried to constant weight and disperse it in water according to the liquid-solid ratio (volume / mass) of 50:1, use 3mol / L hydrochloric acid to adjust the pH of the leaching solution to 0.5, stir and leaching at 19°C and 250rpm 4h, filter and keep the supernatant;

[0066] (2) Utilize the 1mol / L 5-salicylaldoxime (LIX860N-I) prepared in kerosene to carry out two repeated extractions to the filtrate obtained in step 1 under the condition that the organic phase: water ratio (volume / volume) is 6:1, Extract at an extraction temperature of 15°C for 5 minutes to reach extraction equilibrium and then stand for separation;

[0067] (3) Use 0.1mol / L sodium sulfate to back-extract the organic phase extract obtained in step 2. After the back-extraction is balanced, let it stand for separation, and the organic phase raffinate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com