Preparation method of hydrophilic fiber modified water swelling hydrolyzed nitrile rubber

A technology of hydrophilic fiber and nitrile rubber, which is applied in fiber type, fiber treatment, textiles and papermaking, etc., can solve the problems of reducing water absorption and mechanical properties of WSR, achieve excellent performance, improve mechanical properties, and good capacitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0037] Utilize hydrophilic acrylic fiber to prepare the specific application of water-absorbing swelling nitrile rubber, its step is as follows:

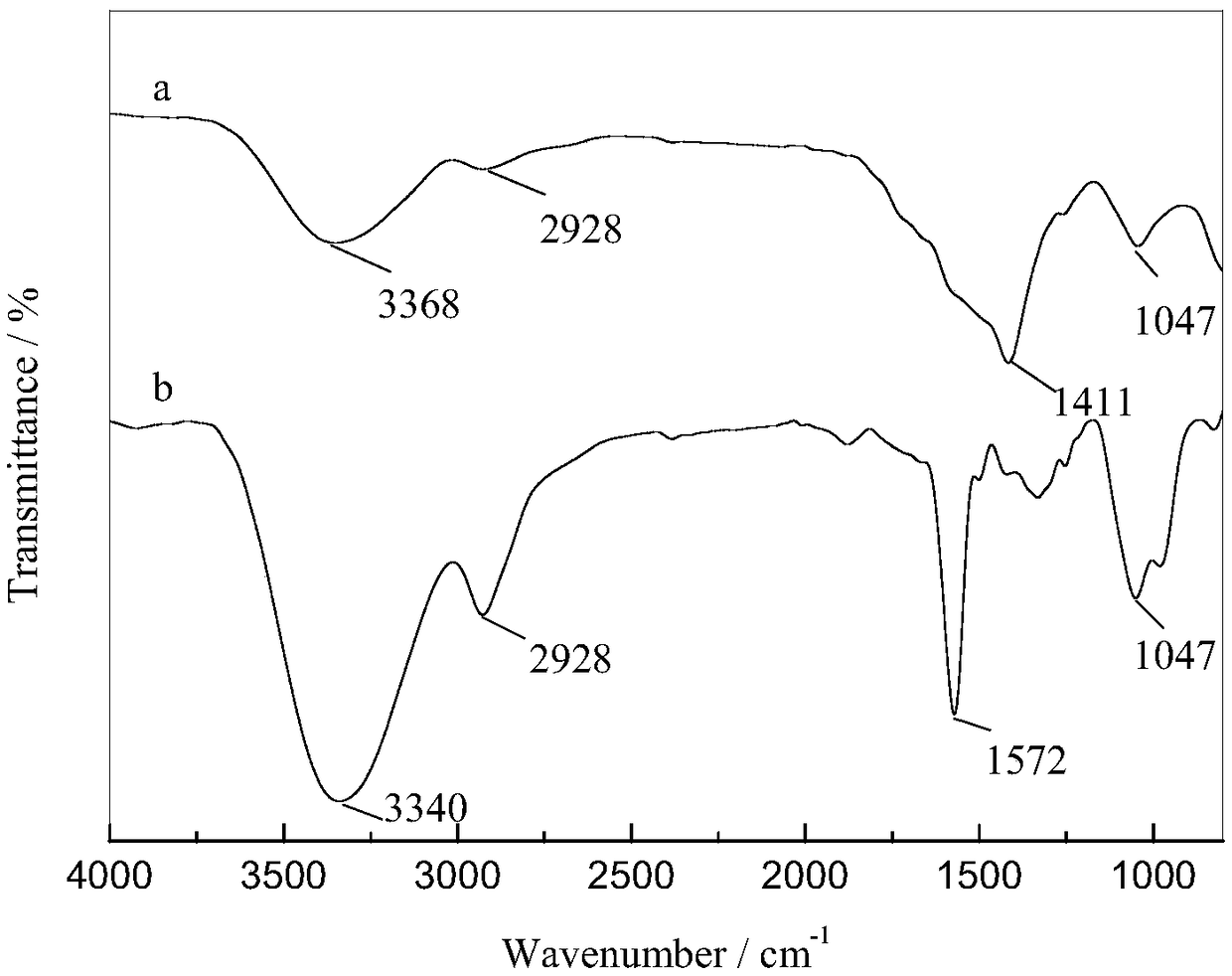

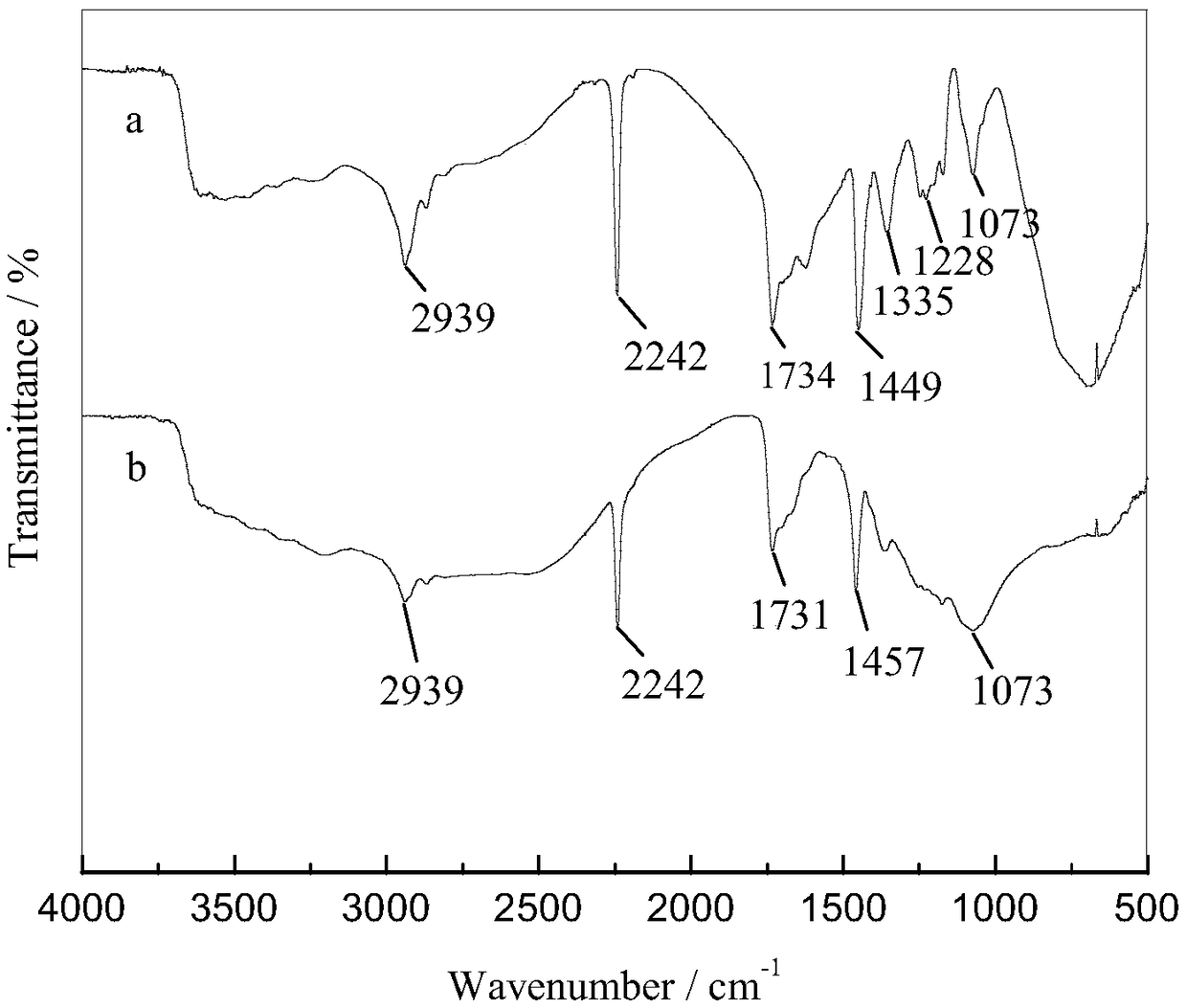

[0038] 1) Dissolve nitrile rubber in acetone, ultrasonically oscillate until the rubber is completely dissolved, then add 3mol / L sodium hydroxide glycerol-water solution, heat up to 50°C, and react for 24 hours, then pour the reaction solution into absolute ethanol , filter out the precipitate, wash with distilled water and dry to obtain hydrolyzed nitrile rubber. Among them, the volume ratio of glycerol to water is 1:9. The infrared spectra of hydrolyzed nitrile rubber and nitrile rubber were measured by Impact420 Fourier transform infrared spectrometer.

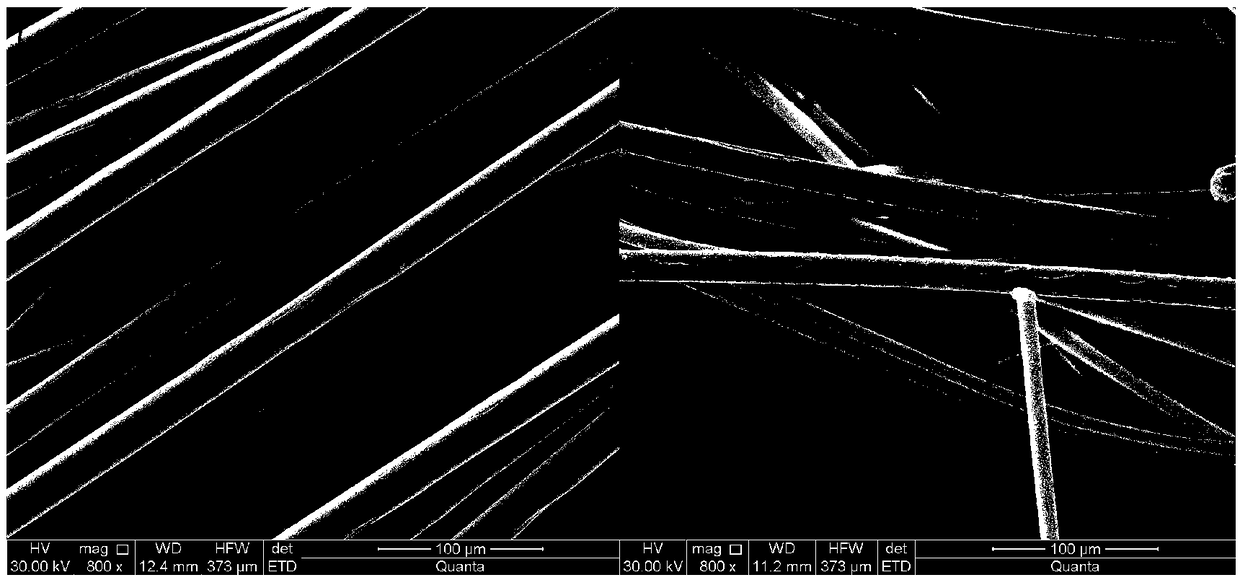

[0039] 2) Immerse the acrylic fiber in the glycerol-water mixed solution, add a certain amount of sodium hydroxide, raise the temperature to 90°C, and react for 3 hours, neutralize it with hydrochloric acid isopropanol solution until the pH is neutral, and filter out the fiber ...

Embodiment 6~11

[0057] 1) Put 100 parts of nitrile / hydrolyzed nitrile rubber in a double-roller open mill for 3~ After 5 minutes, add 1.5 parts, 5 parts of ZnO, 1 part of antioxidant N,N'-di(β-naphthyl)-p-phenylenediamine, and 1.5 parts of vulcanization accelerator 2,2'-dithio Dibenzothiazole, 1.5 parts of vulcanization accelerator N-cyclohexyl-2-benzothiazole sulfenamide, 1.5 parts of sublimed sulfur, each additive is added and mixed for 1 to 2 minutes before adding the next one, Then add 10 parts of hydrophilic acrylic fibers and 60 parts of sodium polyacrylate, and knead for 10 minutes. Finally, add 20 parts of natural gas channel black and 20 parts of precipitated silica into the rubber matrix and knead evenly, and make triangle bags 6 times. , Bo Tong, the next film, stand for 8 hours for later use.

[0058] 2) Put the mixed nitrile rubber obtained in step 1) on the open mill, and then gradually increase the roll distance of the open mill from 2mm to 4mm, and let the rubber material pas...

Embodiment 12~16

[0065] 1) After masticating 100 parts of hydrolyzed nitrile rubber in a double-drum mill for 3 to 5 minutes, add 1.5 parts, 5 parts of ZnO, 1 part of anti-aging agent N-phenyl-2-naphthylamine, 1.5 parts Vulcanization accelerator 2-mercapto benzothiazole, 1.5 parts of vulcanization accelerator N-cyclohexyl-2-benzothiazole sulfenamide, 1.5 parts of sublimed sulfur, each auxiliary agent is added and mixed for 1 After ~2 minutes, add the next one, then add 10 parts of hydrophilic acrylic fiber, 40, 50, 60, 70, 80 parts of sodium polyacrylate, mix for 10 minutes, and finally, mix 20 parts of natural gas tank black and 20 parts of precipitation Add white carbon black to the rubber matrix and knead evenly, pack it into a triangle bag 6 times, thin it out, take it off, and let it stand for 8 hours for later use.

[0066] 2) Put the mixed nitrile rubber obtained in step 1) on the open mill, and then gradually increase the roll distance of the open mill from 2mm to 4mm, and let the rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com