Preparation method of quaternary ammonium salt modified organic magnesium aluminosilicate for thickening oily system

A magnesium aluminum silicate and quaternary ammonium salt technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problem of limited expansion, low electronegativity of magnesium aluminum silicate, thickening of organic magnesium aluminum silicate Low viscosity-increasing ability and other problems, to achieve the effect of increasing viscosity and thickening ability, easy dispersion and swelling, and improved hydrophobic and lipophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

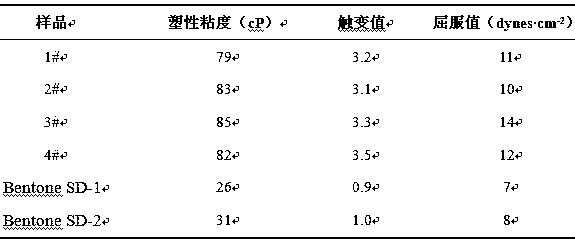

Examples

Embodiment 1

[0024] A quaternary ammonium salt-modified organic magnesium aluminum silicate for thickening an oily system is prepared from the following raw material components in parts by mass according to the following steps:

[0025] (1) First, the mass concentration of 1 part of the substance is 0.01mol L -1 Add dilute phosphoric acid aqueous solution to 100 parts of sodium montmorillonite powder and stir evenly, then add 1 part of beryllium oxide and 5 parts of La 2 o 3 And continue to stir evenly, and then roast at 150 ° C for 5 minutes; then take it out and add 1000 parts of pure water, stir well until the montmorillonite is completely dispersed;

[0026] (2) Next, add 10 parts of quaternary ammonium salt octadecyl trimethyl ammonium chloride to 500 parts of pure water, and heat to 75 ° C, under the condition of full stirring until the quaternary ammonium salt is completely dissolved; then the quaternary ammonium Add the salt solution to the montmorillonite suspension prepared in ...

Embodiment 2

[0028] A quaternary ammonium salt-modified organic magnesium aluminum silicate for thickening an oily system is prepared from the following raw material components in parts by mass according to the following steps:

[0029] (1) First, the mass concentration of 5 parts of the substance is 0.1mol L -1Add dilute phosphoric acid aqueous solution to 100 parts of montmorillonite powder and stir evenly, then add 2 parts of magnesium oxide, 3 parts of copper oxide, 10 parts of Ce 2 o 3 , 5 copies of Ln 2 o 3 And continue to stir evenly, and then roast at 250 ° C for 15 minutes; then take it out and add 2000 parts of pure water, stir well until the montmorillonite is completely dispersed;

[0030] (2) Next, add 15 parts of dioctadecyl dimethyl ammonium chloride and 15 parts of dioctadecyl methyl benzyl ammonium chloride to 800 parts of pure water, and heat to 90°C, stirring thoroughly Under the conditions until the quaternary ammonium salt is completely dissolved; then add the quat...

Embodiment 3

[0032] A quaternary ammonium salt-modified organic magnesium aluminum silicate for thickening an oily system is prepared from the following raw material components in parts by mass according to the following steps:

[0033] (1) Firstly, the concentration of 3 substances is 0.05mol L -1 Add dilute phosphoric acid aqueous solution to 100 parts of montmorillonite powder and stir evenly, then add 1 part of magnesium oxide, 1 part of copper oxide, 1 part of zinc oxide, 3 parts of La 2 o 3 , 3 copies of Ce 2 o 3 , 3 copies of Ln 2 o 3 And continue to stir evenly, and then roast at 200 ° C for 10 minutes; then take it out and add 1500 parts of pure water, stir well until the montmorillonite is completely dispersed;

[0034] (2) Next, add 5 parts of octadecyl trimethyl ammonium bromide, 5 parts of dioctadecyl dimethyl ammonium bromide, and 5 parts of octadecyl dimethyl benzyl ammonium chloride to 700 parts Pure water, and heated to 80 ° C, under the condition of sufficient stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com