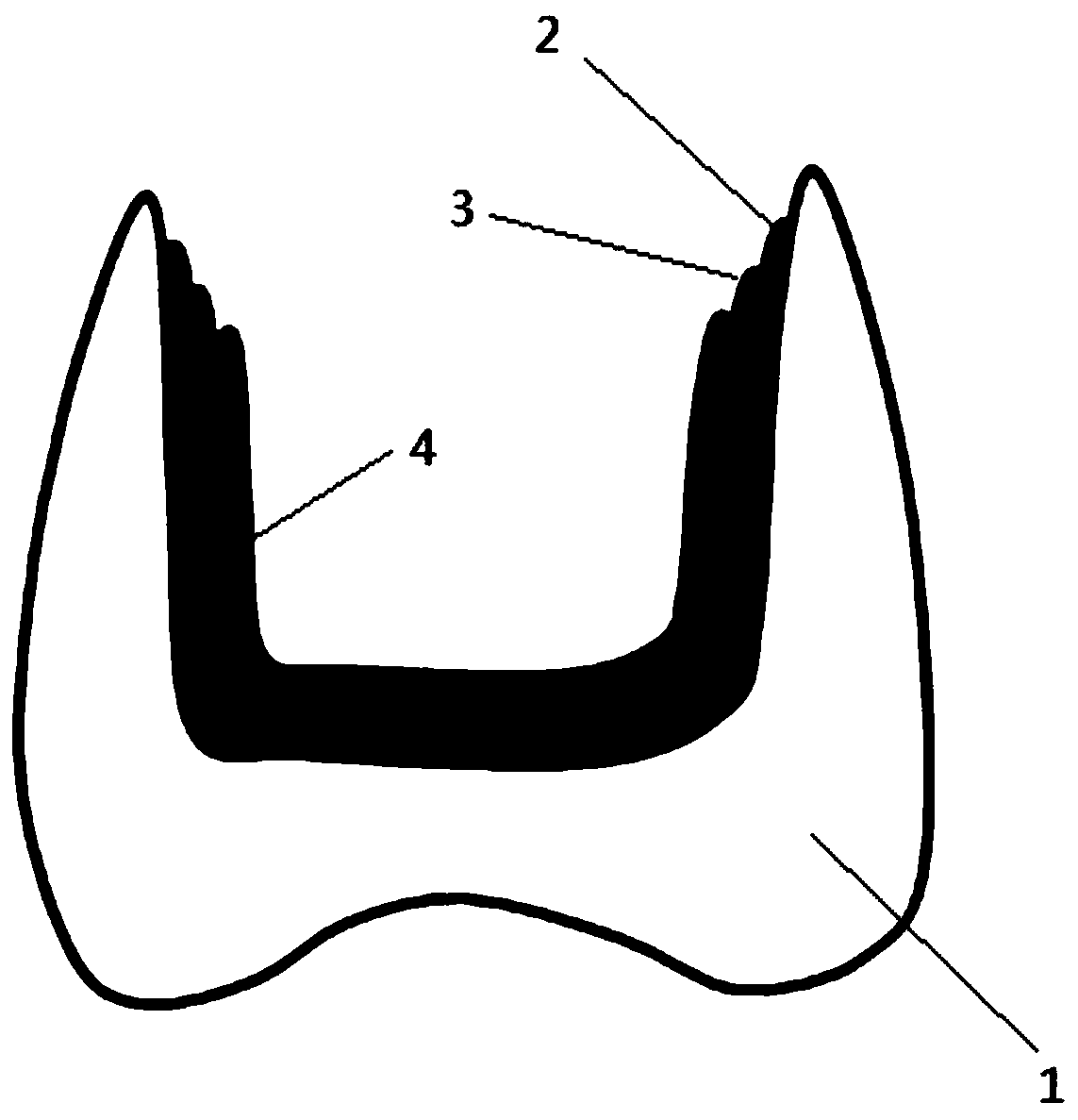

Masking zirconium oxide restoration

A restoration, zirconia technology, applied in dental prosthesis, medical science, dentistry, etc., to achieve high strength and toughness, improved bonding strength, good aesthetic restoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] 1. Preparation of zirconia restorations

[0054] Method 1. The zirconia restoration is prepared by colloidal deposition layer-by-layer additive method. The green body is heated at a heating rate of 1-10°C / s to 120-200°C for 1-2 hours, and then dried at a heating rate of 1-10°C / s. 10-50℃ / s heating up to 700-1100℃, bisque firing in an oxidizing atmosphere, holding for 1-2 hours to obtain a bisque block, and then processing the bisque block to obtain a zirconia restoration by computer-aided design and computer-aided manufacturing bisque. Method 2. The zirconia restoration uses the colloidal deposition layer-by-layer additive method to prepare the biscuit block, and then processes the biscuit block to obtain the zirconia restoration body biscuit, and the zirconia restoration The green body is heated to 120-200°C at a heating rate of 1-10°C / s and dried for 1-2 hours, and then heated to 700-1100°C at a heating rate of 10-50°C / s. Hours, get zirconia restoration bisque.

[0...

manufacture example

[0078] Alumina-doped Y Partially Stabilized ZrO 2 The sol preparation method is: alumina (1-5mol%) doped with Y (2-6mol%) to partially stabilize ZrO 2 The example of sol manufacturing is as follows: The method of reverse dripping is used to prepare alumina-doped Y-stabilized ZrO 2 Sol, the prepared precipitant NH 4 HCO 3 (10-50%)+NH 3 ·H 2 O solution (50-90%) is placed in the Erlenmeyer flask, and the Erlenmeyer flask is placed in a magnetic stirrer or a constant temperature water bath reactor with stirring, and the prepared Al-containing 3+ , Y 3+ 、Zr 4+ The mother liquor includes zirconium hydroxide (ZrO(OH) 2 ·nH 2 O≥99%), zirconium oxychloride (ZrOCl 2 ·8H 2 O≥99%), zirconium nitrate (Zr(NO 3 ) 4 ·5H 2 One of O≥99%); Yttrium nitrate Y (NO 3 ) 3 ·6H 2 O, yttrium chloride (YCI 3 ·6H 2 One of O≥99.99%); aluminum chloride (AlCl 3 ≥99%), aluminum nitrate (Al(NO 3 ) 3 9H 2 One of O), slowly drop into the precipitant, and vigorously stir to make it fully rea...

Embodiment 1

[0097] Example 1. Abutment tooth A2 color restoration one

[0098] The white zirconia restoration body was dried at 200°C for 1 hour at a heating rate of 5°C / s. Then heat up to 1050°C at a heating rate of 10°C / s, bisque-fire in an oxidizing atmosphere, and keep warm for 2 hours to obtain bisque. The bisque was soaked in A2 staining solution and treated at 400°C for 10 minutes. Then process the coating opaque layer. If the patient’s abutment is deep or the tetracycline tooth or metal post core, the thickness of the zirconia crown is greater than 0.7mm, then light opaque treatment is adopted, and the above-mentioned opaque sol and opaque sol are used as the coating material One of mixtures, opaque pastes, opaque sols, and opaque powder mixtures, for example by mixing ZrO with a molar concentration of 1-10mol / L 2 -xH 2 O sol 90wt% + 10wt% AlN powder, add appropriate amount of deionized water, prepare a coating slurry with a solid phase amount of 5-20wt% by planetary ball milli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com