Compensation control method for input filtering capacitive current of CRM Boost PFC converter

A technology of input filtering and capacitive current, applied in the field of compensation control, can solve problems such as zero-crossing distortion of input current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

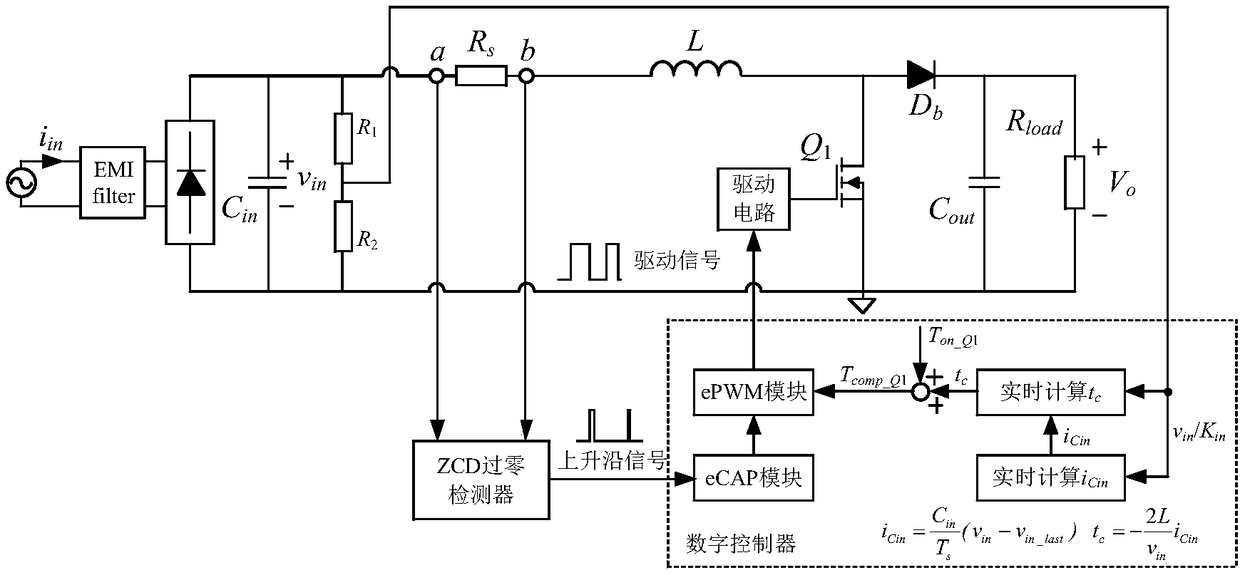

[0064] Embodiment 1: Based on the TMS320F28335 digital controller and variable on-time control, a digital control method for implementing input filter capacitor current compensation for a CRM Boost PFC converter using a freewheeling diode

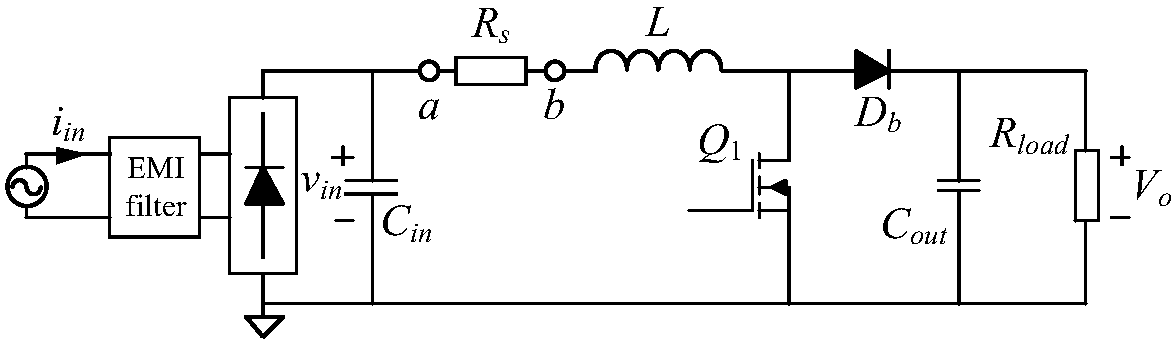

[0065] figure 1 It is the main circuit of CRM Boost PFC converter using freewheeling diode, including EMI filter, rectifier bridge, input filter capacitor, boost inductor, main switch tube, freewheeling diode, output filter capacitor and load.

[0066] The circuit parameters of the CRM Boost PFC converter used in the example are: boost inductance L=240μH, input filter capacitor capacitance C in = 100nF. The test conditions are: line frequency 50Hz, AC input voltage 110V and 220V, output bus voltage 400V, full load output power 200W.

[0067] In this experiment, whether the input current THD of compensation control is used or not is tested under the conditions of 20%, 40%, 50%, 60%, 80% and 100% load rate respectively.

[0068] image 3 ...

Embodiment 2

[0086] Embodiment 2: Based on the TMS320F28335 digital controller and constant on-time control, a digital control method for implementing input filter capacitor current compensation for a CRM Boost PFC converter using a synchronous rectification switch tube

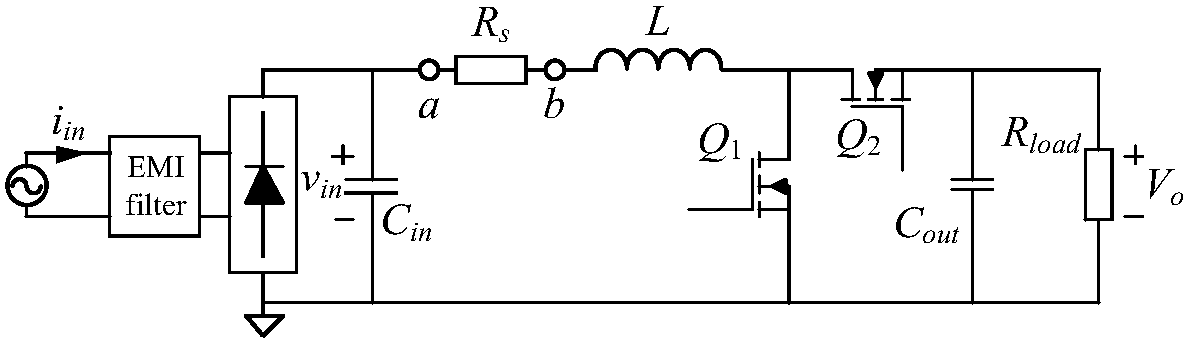

[0087] figure 2 The main circuit of the CRM Boost PFC converter using a synchronous rectification switch tube includes an EMI filter, a rectifier bridge, an input filter capacitor, a boost inductor, a main switch tube, a synchronous rectification switch tube, an output filter capacitor and a load.

[0088] The circuit parameters of the CRM Boost PFC converter used in the example are: boost inductance L=240μH, input filter capacitor capacitance C in = 100nF. The test conditions are: line frequency 50Hz, AC input voltage 110V and 220V, output bus voltage 400V, full load output power 200W.

[0089] Figure 4 In order to realize the digital control circuit of compensation control for the CRM Boost PFC converter using sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com