Composite lithium battery cathode with high energy storage efficiency, preparation method thereof and lithium battery

A composite, high energy storage technology, applied in battery electrodes, electrode carriers/current collectors, secondary batteries, etc., to increase battery capacity, ensure uniformity, and improve swelling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

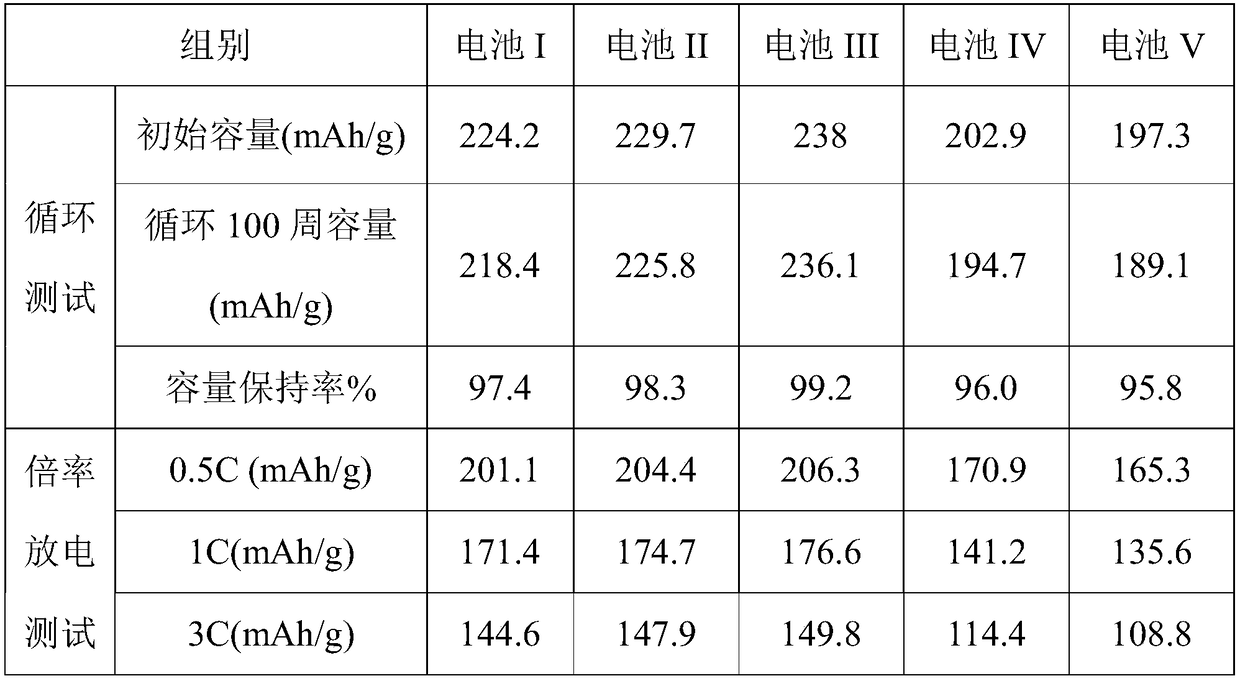

Embodiment 1

[0024] Example 1 Preparation of High Energy Storage Efficiency Composite Lithium Battery Positive Electrode I

[0025] Step 1. Preparation of modified carbon nanotube / carbon nanofiber composite membrane: dissolving polyacrylonitrile in dimethyl sulfoxide to form a polyacrylonitrile solution with a mass fraction of 8% wt., and then making the mass ratio 0.5: 3. The modified carbon nanotubes and polyacrylonitrile solution are mixed, ultrasonically dispersed at room temperature to form a spinning solution, and then the ambient temperature is 15-30°C, and the ambient humidity is 5%-70%. Using a high-voltage electrostatic spray device, electrostatic The generator voltage is 10kV-20kV, the distance between the metal needle and the take-up is 12cm, the flow rate is 0.5mL / h, and the spinning speed is 500rpm / min, the spinning solution is prepared into a nanofiber film, and then the nanofiber Transfer the fiber membrane to a tube furnace, raise the temperature to 150°C at a heating rate...

Embodiment 2

[0029] Example 2 Preparation of High Energy Storage Efficiency Composite Lithium Battery Positive Electrode II

[0030] Step 1. Preparation of modified carbon nanotube / carbon nanofiber composite membrane: dissolving polyacrylonitrile in dimethyl sulfoxide to form a polyacrylonitrile solution with a mass fraction of 12% wt., and then making the mass ratio 2: 10 modified carbon nanotubes and polyacrylonitrile solution are mixed, ultrasonically dispersed at room temperature to form a spinning solution, and then at an ambient temperature of 15-30°C and an ambient humidity of 5%-70%, use a high-voltage electrostatic spray device to electrostatically The generator voltage is 10kV-20kV, the distance between the metal needle and the yarn collector is 15cm, the flow rate is 3mL / h, and the spinning speed is 3000rpm / min, the spinning solution is prepared into a nanofiber film, and then the nanofiber Transfer the film to a tube furnace, raise the temperature to 200°C at a heating rate of ...

Embodiment 3

[0034] Example 3 Preparation of High Energy Storage Efficiency Composite Lithium Battery Cathode III

[0035] Step 1. Preparation of modified carbon nanotube / carbon nanofiber composite membrane: dissolving polyacrylonitrile in dimethyl sulfoxide to form a polyacrylonitrile solution with a mass fraction of 10% wt., and then adjusting the mass ratio to 0.15: 8 modified carbon nanotubes and polyacrylonitrile solution are mixed, ultrasonically dispersed at room temperature to form a spinning solution, and then at an ambient temperature of 15-30°C and an ambient humidity of 5%-70%, use a high-voltage electrostatic spray device to electrostatically The generator voltage is 10kV-20kV, the distance between the metal needle and the yarn collector is 14cm, the flow rate is 2mL / h, and the spinning speed is 1500rpm / min, the spinning solution is prepared into a nanofiber film, and then the nanofiber Transfer the film to a tube furnace, raise the temperature to 180°C at a heating rate of 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com