Preparation method of composite air cylinder

A technology of composite materials and composite material layers, which is applied in the field of composite material pressure vessel manufacturing, can solve the problems of excessive load strength in the head area, conservative design of head strength, and failure to consider the strength of the inner liner head, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

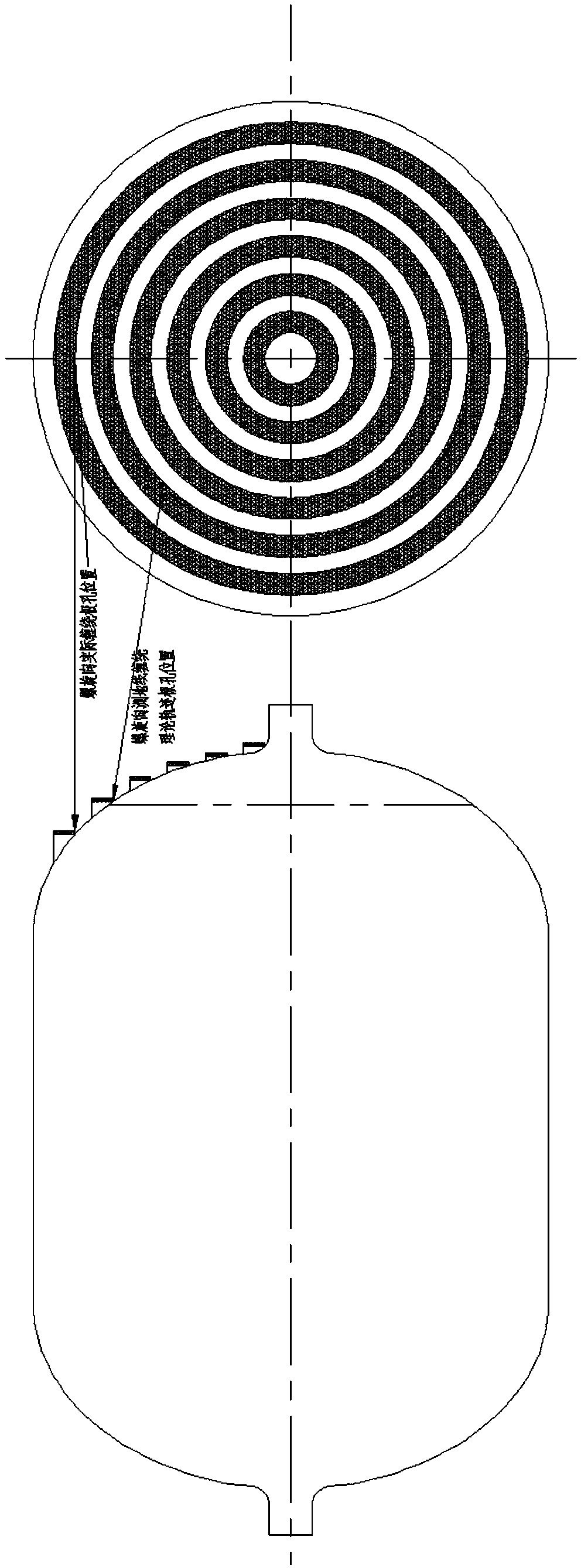

[0030] A preparation method of a composite material gas cylinder, the composite material gas cylinder includes an aluminum alloy lining and a composite material layer; the steps of the method include:

[0031] (1) According to the design requirements of the composite gas cylinder, carry out the strength design of the composite material layer of the composite gas cylinder;

[0032] (2) Lay-up design is carried out for each winding layer according to the geodesic method, and the adjacent spiral winding layer is wound with head reaming according to 1.2-1.3 times the bandwidth, and the strength of the barrel section is checked;

[0033] (3) According to the theory of gas cylinder design, the strength of the head composite material layer is higher than that of the cylinder body, and the bearing capacity of the inner liner head is not considered in the strength design process, resulting in excess strength of the gas cylinder head. The thickness of the material layer achieves the pur...

Embodiment

[0040] A preparation method of a composite material gas cylinder, the composite material gas cylinder includes an aluminum alloy lining and a composite material layer; the steps of the method include:

[0041] (1) The design strength of a 9L composite material gas cylinder is 70MPa, the outer diameter of the inner lining is 167mm, the length is 516mm, and the reinforcing fiber is T1000.

[0042] (2) Each winding layer is designed according to the geodesic method, and the adjacent spiral winding layer is wound with head reaming according to 1.2-1.3 times the bandwidth, and the laying sequence is ±90° 2 / ±11° / ±90° / ±16° / ±90° / ±21° / ±90° / ±27° / ±90° / ±33°;

[0043](3) Keep the original winding angle in the barrel section, and carry out head reaming winding in the head area according to 1.6-1.7 times the bandwidth, and the head winding angle becomes 11°, 18°, 25°, 33° and 42°;

[0044] (4) Winding molding is carried out according to the layup angle and layup sequence described in (2) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Burst strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com