Three-directional non-yielding fiber cloth and production method thereof

A fiber cloth, non-yield technology, applied in the field of three-way non-yield fiber cloth and its preparation, can solve the problems of high transverse strength of unidirectional cloth, reduced product strength, decreased fiber strength, etc., to reduce engineering costs, improve strength, Reduce the effect of falloff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

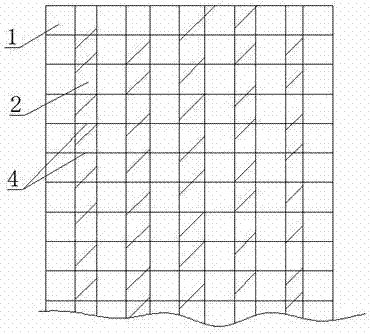

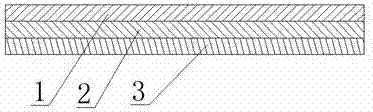

[0025] Such as figure 1 , figure 2 As shown, a three-way non-yielding fiber cloth includes three layers of fiber layers and connecting wires 4 connecting the three layers of fiber layers. The three layers of fiber layers include 0-degree fiber layer 1, 45-degree fiber layer 2 and 135-degree fiber layer 3, the 0-degree fiber layer 1 is composed of fiber bundles extending in the 0-degree direction, the 45-degree fiber layer 2 is composed of fiber bundles extending in the 45-degree direction, and the 135-degree fiber layer Layer 3 consists of fiber bundles extending in a direction of 135 degrees.

[0026] Thus there is a 45-degree angle between the fiber bundles of the 0-degree fiber layer 1 and the fiber bundles of the 45-degree fiber layer 2, and a 90-degree angle between the fiber bundles of the 45-degree fiber layer 2 and the fiber bundles of the 135-degree fiber layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com