Automatic manual power shift with power reversing transmission box

A technology of power shifting and reversing transmission, applied in the field of tractors, can solve the problems of ineffective use of engine power, low efficiency of hydraulic transmission parts, unfavorable speed ratio matching of tractors, etc., so as to maintain high efficiency transmission, compact structure and gear position many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

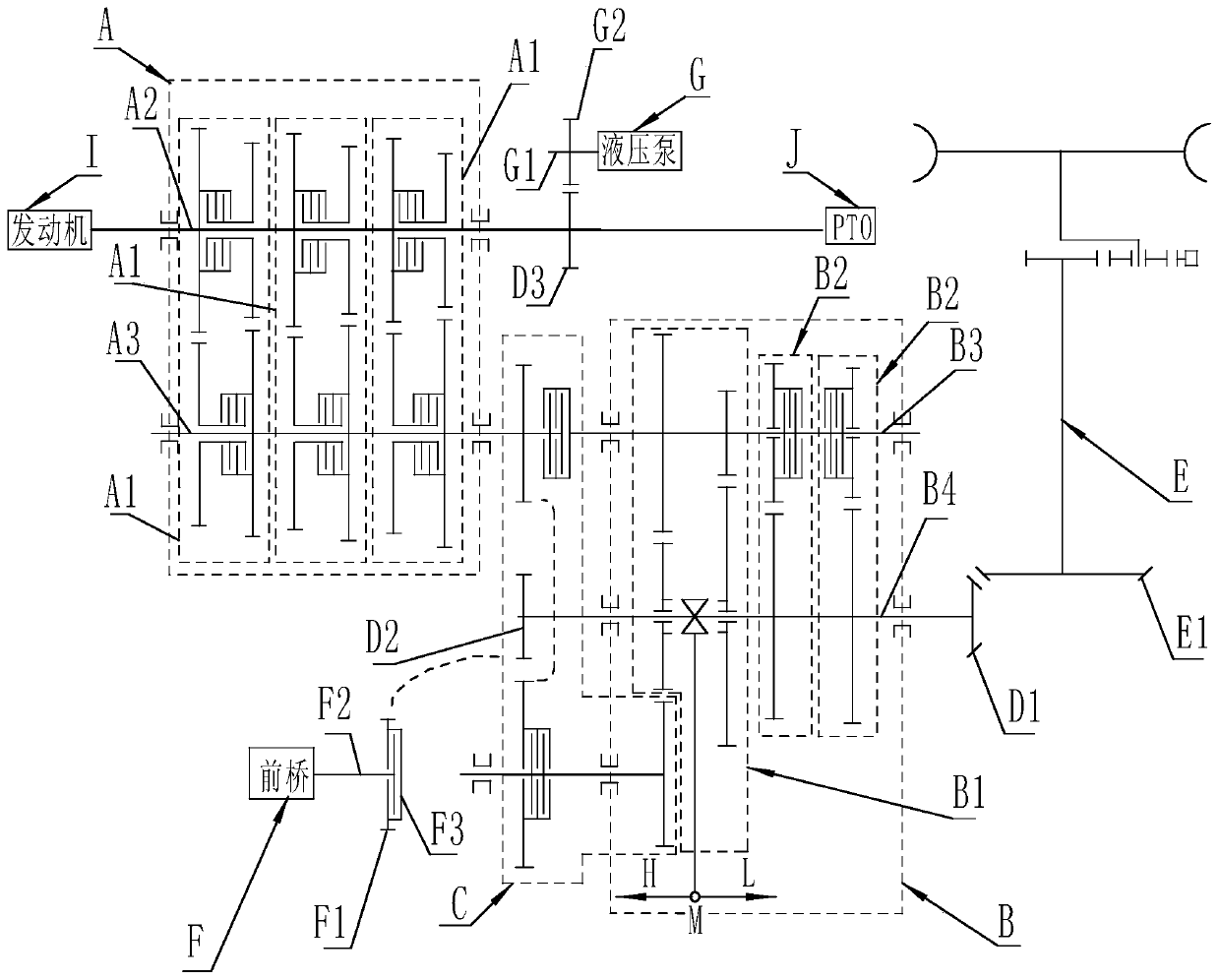

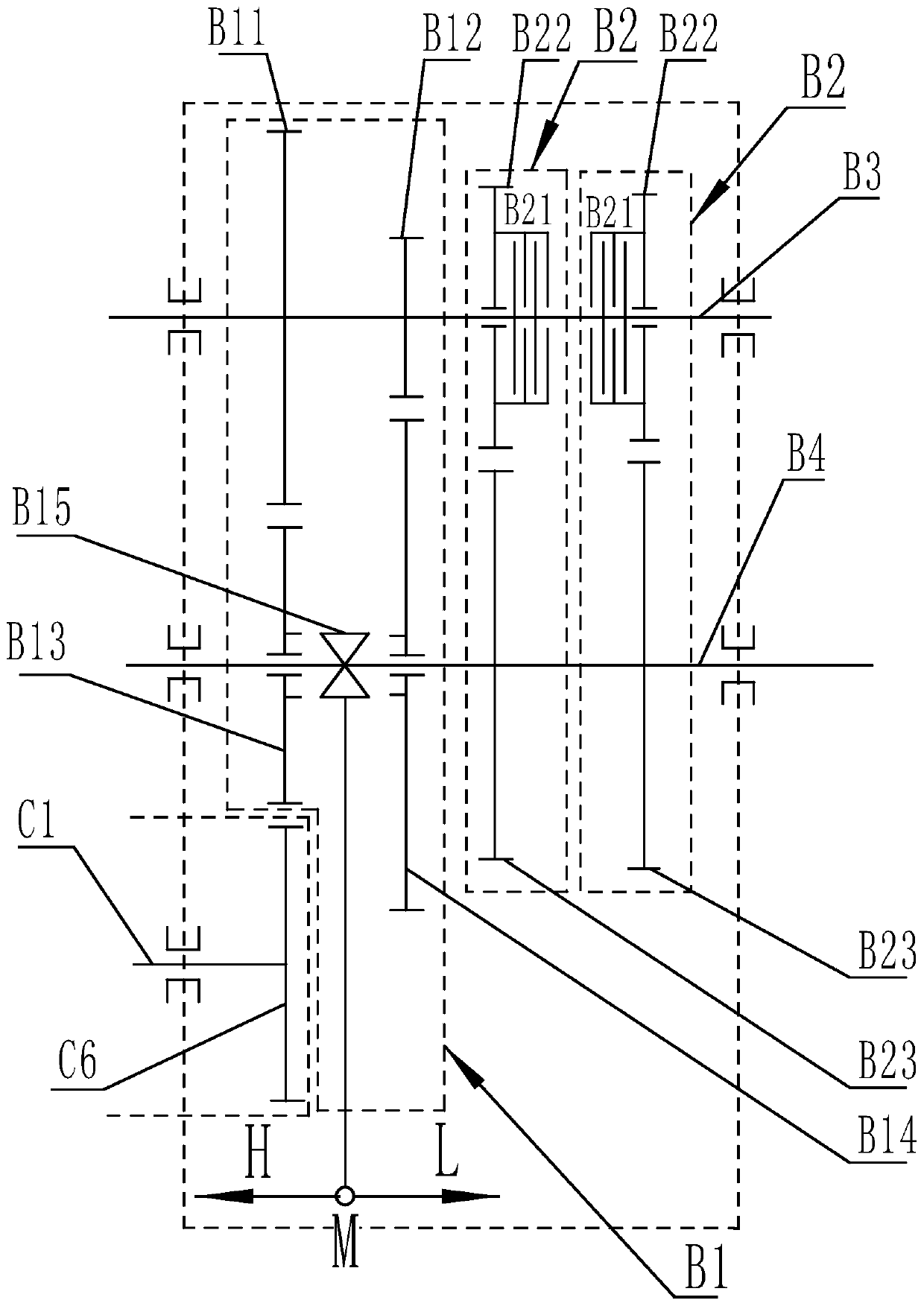

[0027] Such as figure 1 As shown, an automatic manual power shifting belt power reversing transmission box includes a shifting transmission main box A, a power reversing device C and a shifting transmission auxiliary box B connected in sequence. The number of gears of the gearshift main box A multiplied by the number of stages of the gearshift auxiliary box B is the total forward gear number of the present invention, and the gear numbers of the forward gear and the reverse gear of the power reversing device C can Keep consistent to realize the shuttle reversing function, which can be switched in real time according to the driver's intention.

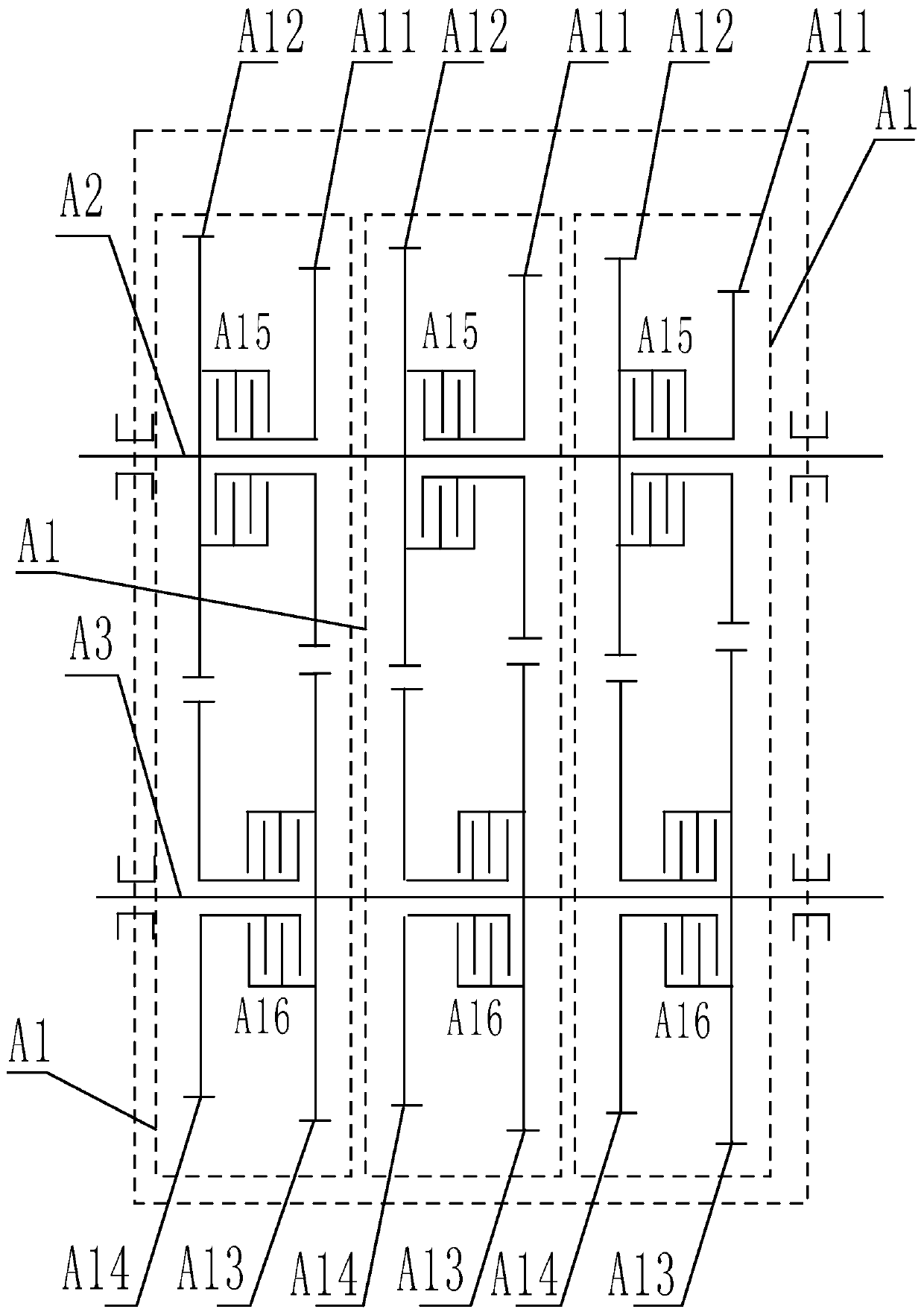

[0028] See figure 1 and figure 2 , the shift transmission main box A includes the main box input shaft A2, the main box output shaft A3 and three sets of two-speed shift assemblies A1 (it should be pointed out that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com