High-power semiconductor module suitable for balancing heat of internal power switch chip in short-circuit condition

A technology of power switch chips and power semiconductors, applied in semiconductor devices, circuits, electric solid devices, etc., can solve the problem that the temperature of parallel chips cannot be taken into account, and achieve the effects of simple structure, easy integration, and improved reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

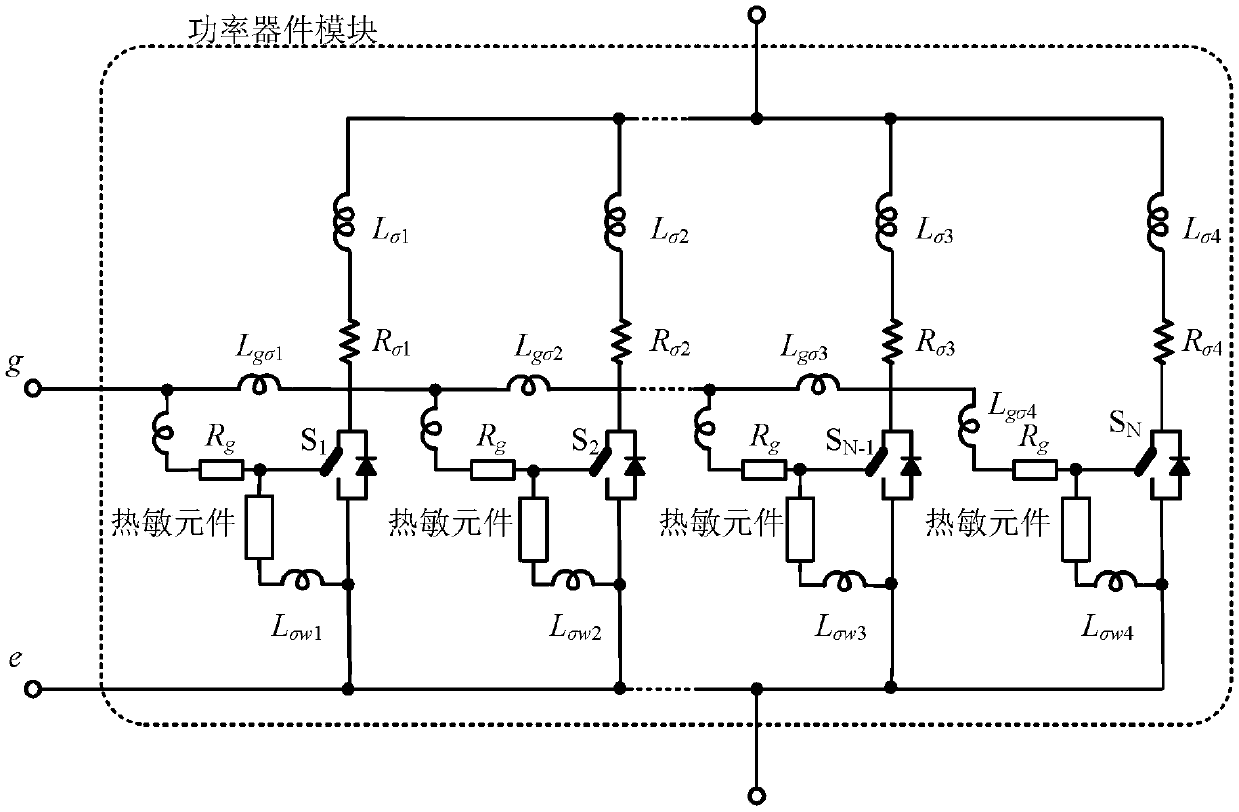

[0028] Embodiment 1 uses a negative temperature coefficient thermistor as a heat equalization circuit under the condition of a short-circuit condition of an IGBT module connected in parallel with a chip of a thermal element, such as figure 2 shown, the thermistor R NTC It is connected in parallel with the G (gate) and E (emitter) terminals of the IGBT chip, and connected with the device gate drive resistor R g A heat balance control circuit for parallel chips is formed. R NTC It directly reflects the device temperature and has a negative temperature coefficient. In the case of an external short circuit, when the temperature of a chip in the parallel chip is too high, the R of the chip surface NTC As the temperature rises, the resistance decreases, the driving voltage applied to the IGBT decreases, the resistance between the emitter and the collector of the IGBT increases, and the current flowing through the IGBT chip decreases, making the thermal stress of the parallel chi...

Embodiment 2

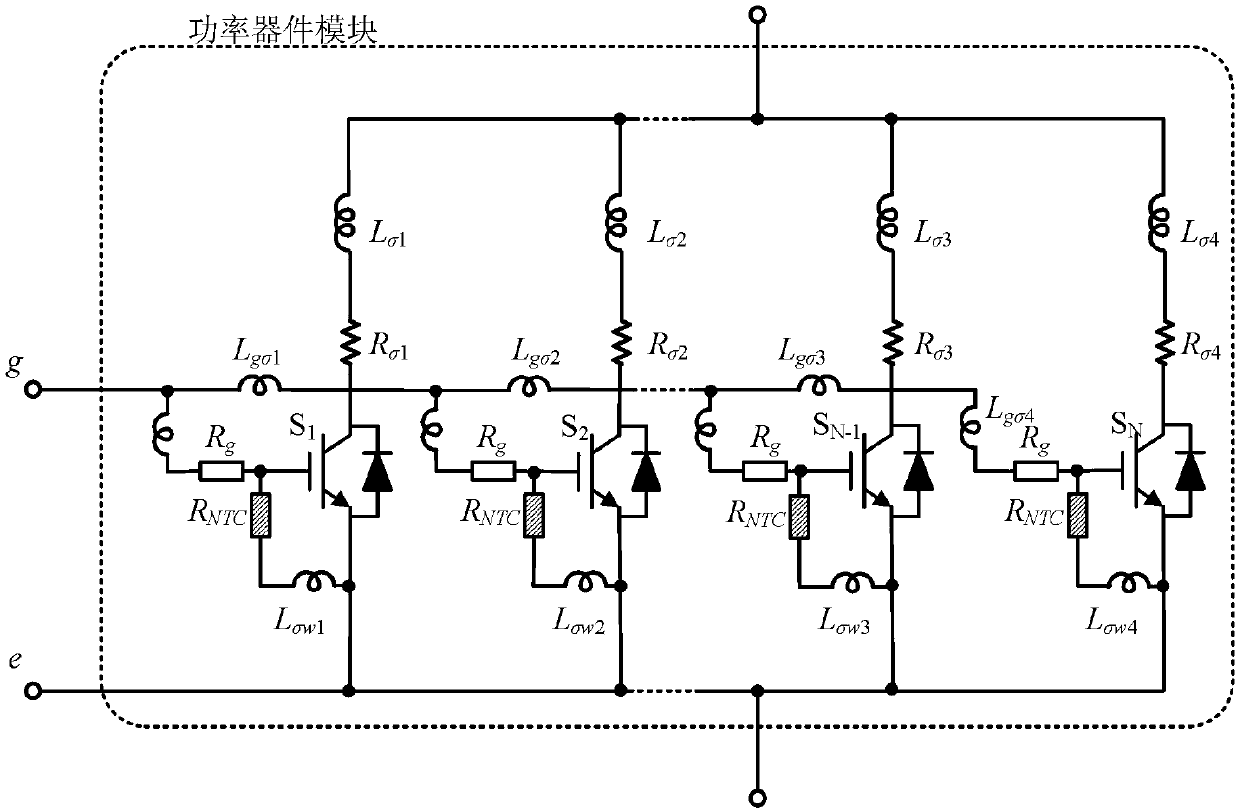

[0029] Embodiment 2 A thermal equalization circuit of a SiC MOSFET power module using a thermistor as a thermal element under short-circuit conditions, such as image 3 shown, the thermistor R NTC It is connected in parallel with the G (gate) and E (emitter) terminals of the internal chip of the SiC MOSFET power module, and connected with the gate drive resistor R g Constitutes a current equalizing circuit. In the case of an external short circuit, when the temperature of a device in parallel is too high, the R next to the device NTCAs the temperature rises, the resistance value decreases, the gate drive voltage applied to the MOSFET decreases, and the resistance between the emitter and collector of the MOSFET increases, which reduces the current flowing through the MOSFET chip and makes the thermal stress of the parallel chip more balanced under short-circuit conditions.

[0030] In the above embodiment, a negative temperature coefficient thermistor is used as the thermal e...

Embodiment 3

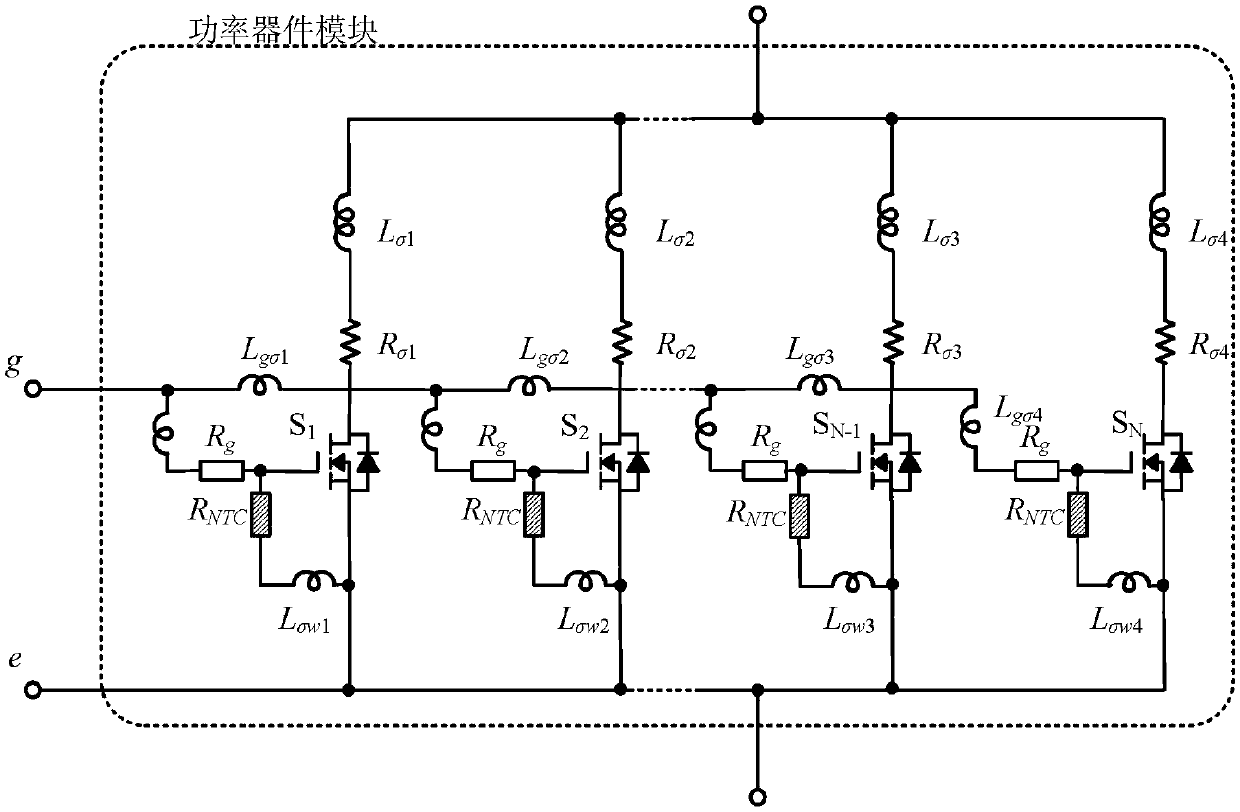

[0041] Embodiment 3 uses a thermal switch as a heat equalization circuit under the short-circuit condition of the IGBT module parallel chip of the thermal element, such as Figure 5 shown, the thermal switch and resistor divider R p In series, then in parallel with the G (gate) and E (emitter) terminals of the IGBT chip, and the gate drive resistor R g A parallel chip current sharing control circuit is formed. The thermal switch is normally open at low temperature and closed when the temperature exceeds the threshold; under short-circuit conditions, when the temperature of the parallel chip exceeds the threshold, the thermal switch is closed, and the driving voltage is equal to the resistance R p For the above parallel voltage divider value, the voltage decreases and the on-resistance increases, thereby limiting the short-circuit current and sharing the current.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com