RESURF GaN-based Schottky barrier diode based on field plate and P-type GaN cap layer

A Schottky potential and diode technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems affecting the forward turn-on voltage and reverse withstand voltage of the device, difficult performance indicators, and low diffusion coefficient. , to achieve the effect of high critical breakdown electric field, excellent transient characteristics and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

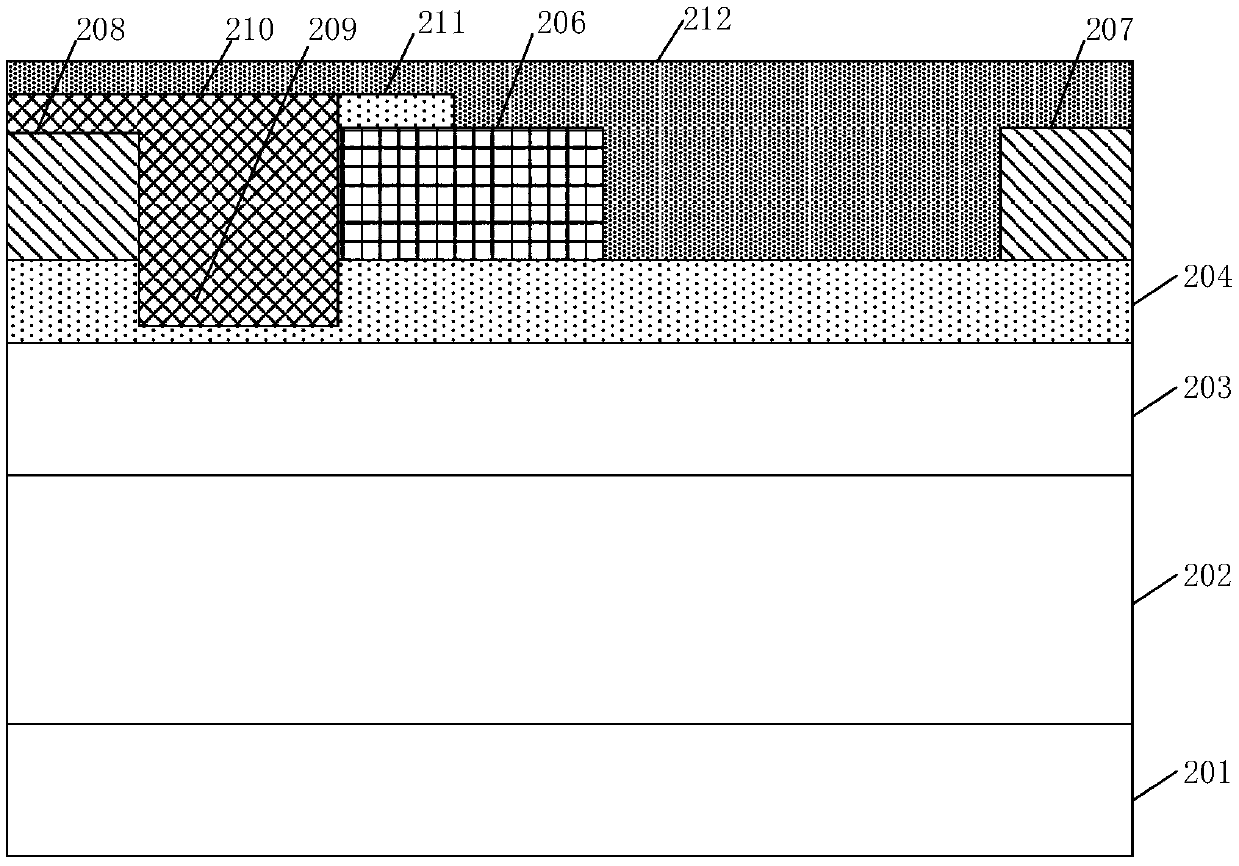

[0030] See figure 1 , figure 1 A RESURFGaN-based Schottky barrier diode with a P-type GaN cap layer provided for an embodiment of the present invention includes: a substrate layer 201, a buffer layer 202 on the substrate layer 201, and a channel on the buffer layer 202 layer 203, a barrier layer 204 on the channel layer 203, a cathode and a compound anode at both ends of the barrier layer 204, a P-type GaN cap layer connected to the compound anode and located on the barrier layer 204 206, the base 211 connected to the compound anode and located on the P-type GaN cap layer 206, covering the barrier layer 204, the P-type GaN cap layer 206, the base 211, the The composite anode and the passivation layer 212 on the cathode, wherein the cathode is a cathode ohmic contact 207 , and the composite anode includes an anode ohmic contact 208 and an anode Schottky contact 210 .

[0031] The P-type GaN cap layer and the barrier layer of the present invention form a PN junction, and two-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com