Supercapacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

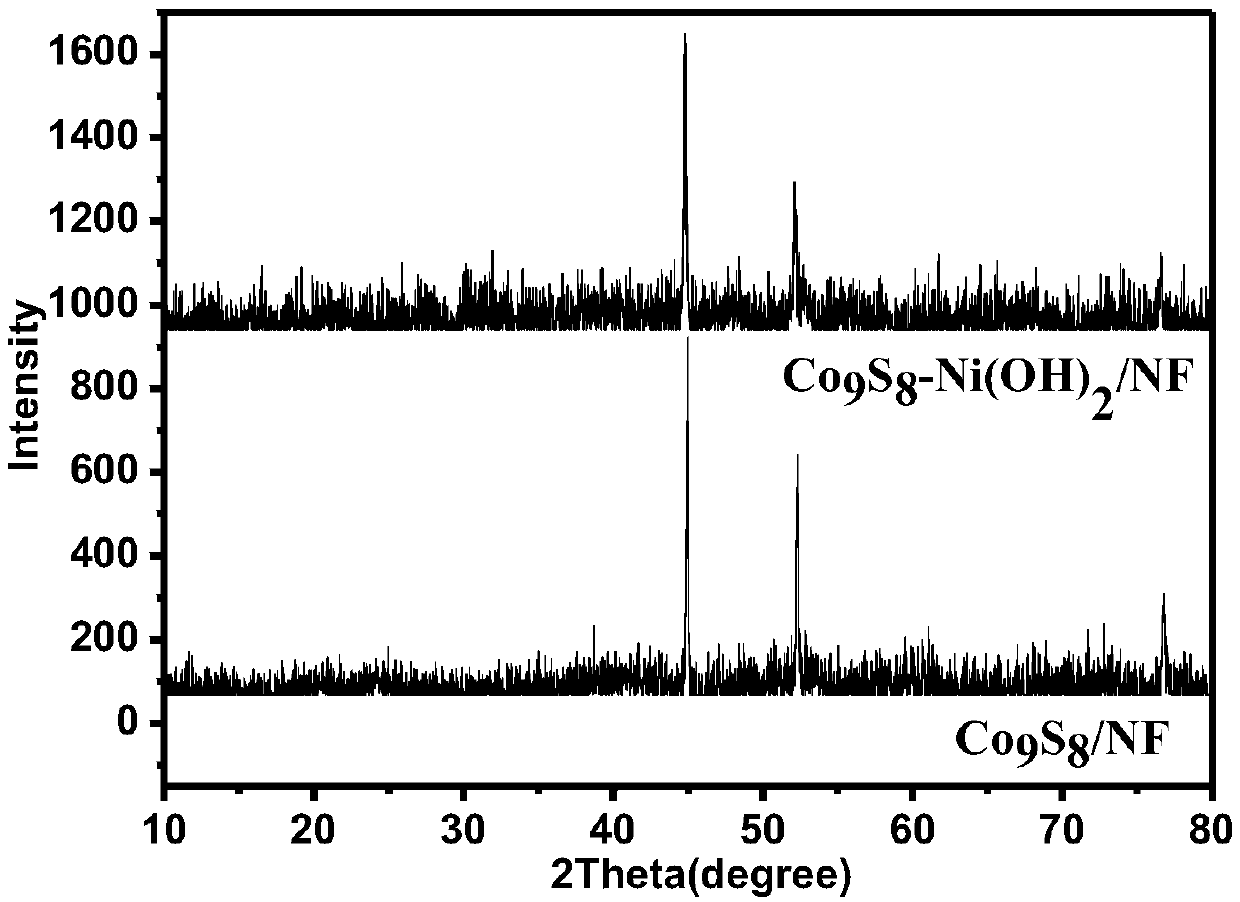

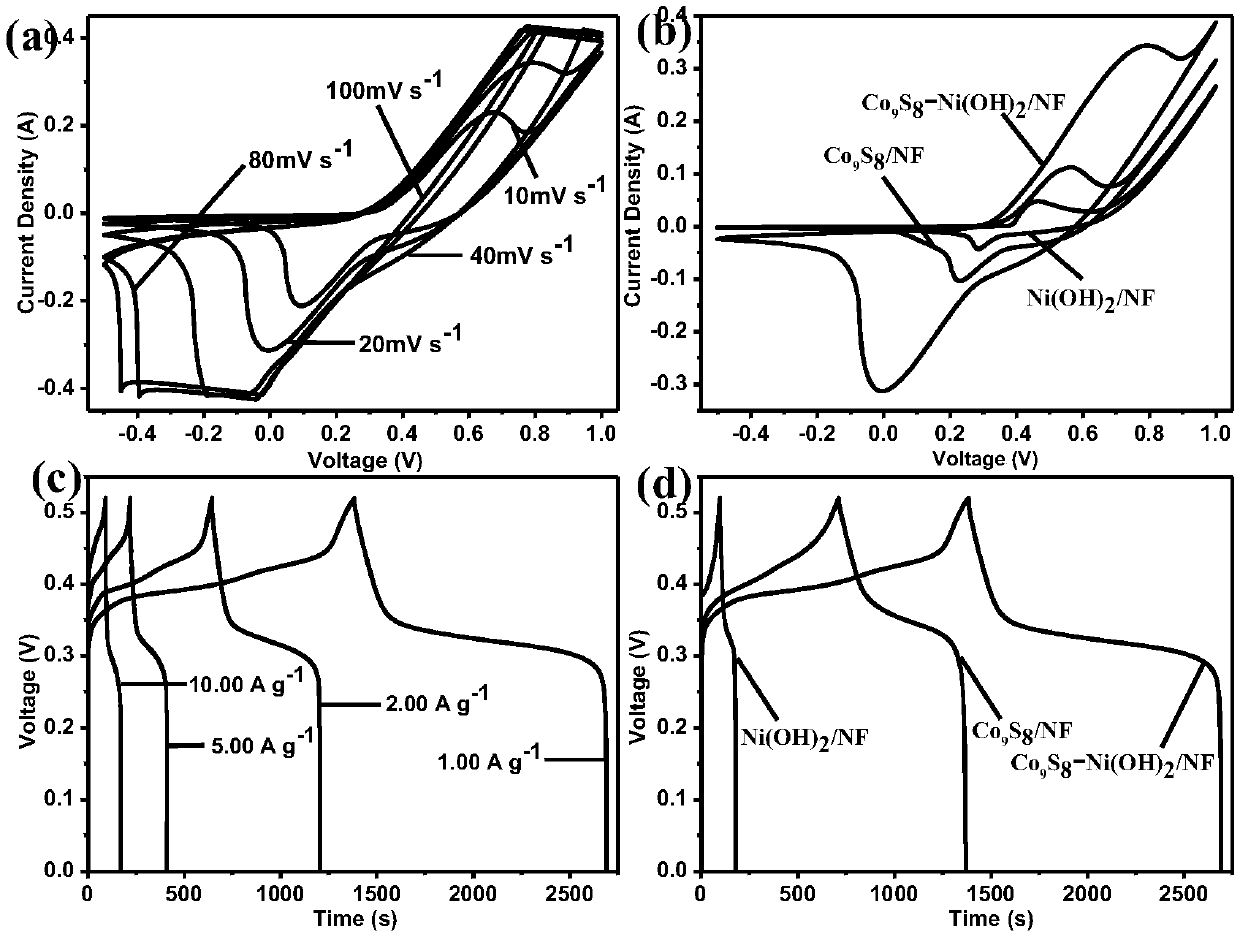

[0031] (1)Co 9 S 8 Preparation of / NF samples:

[0032] Weigh 1mmol of CoCl 2 ·6H 2 0 and 5 mmol of urea in a beaker, add deionized water therein, and magnetically stir for 15 minutes to completely dissolve, then add the gained transparent pink solution into a polytetrafluoroethylene reactor, add pretreated nickel foam and carry out hydrothermal Reaction, 100°C, 7h; after naturally cooling to room temperature, take out the nickel foam, wash with water and alcohol several times, and dry to obtain Co(CO 3 ) 0.35 Cl 0.20 (OH) 1.10 Precursor samples. Weigh 0.25mmol Na 2 S, add deionized water to it, stir magnetically for 15 minutes until it is completely dissolved, then add the obtained transparent solution into a polytetrafluoroethylene reaction kettle, add precursor samples for hydrothermal reaction, 100 ° C, 5 h; wait for natural cooling to room temperature After that, the nickel foam was taken out, washed and dried to obtain Co 9 S 8 / NF samples. Let cool and set a...

Embodiment 2

[0036] (1)Co 9 S 8 Preparation of / NF samples:

[0037] Weigh 2mmol of CoCl 2 ·6H 2 0 and 10 mmol of urea in a beaker, add deionized water therein, and magnetically stir for 15 minutes until completely dissolved, then add the resulting transparent pink solution into a polytetrafluoroethylene reactor, add pretreated foamed nickel for hydrothermal Reaction, 100°C, 7h; after naturally cooling to room temperature, take out the nickel foam, wash with water and alcohol several times, and dry to obtain Co(CO 3 ) 0.35 Cl 0.20 (OH) 1.10 Precursor samples. Weigh 0.5mmol Na 2 S, add deionized water to it, stir magnetically for 15 minutes until it is completely dissolved, then add the obtained transparent solution into a polytetrafluoroethylene reaction kettle, add precursor samples for hydrothermal reaction, 100°C, 5h; wait for natural cooling to room temperature After that, the nickel foam was taken out, washed and dried to obtain Co 9 S 8 / NF samples. Let cool and set aside...

Embodiment 3

[0041] (1)Co 9 S 8 Preparation of / NF samples:

[0042] Weigh 3mmol of CoCl 2 ·6H 2 0 and 15mmol of urea in a beaker, add deionized water therein, and magnetically stir for 15min to dissolve completely, then add the gained transparent pink solution in the reaction kettle of polytetrafluoroethylene, add the pretreated foamed nickel to carry out hydrothermal Reaction, 100°C, 7h; after naturally cooling to room temperature, take out the nickel foam, wash with water and alcohol several times, and dry to obtain Co(CO 3 ) 0.35 Cl 0.20 (OH) 1.10 Precursor samples. Weigh 0.75mmol Na 2 S, add deionized water to it, stir magnetically for 15 minutes until it is completely dissolved, then add the obtained transparent solution into a polytetrafluoroethylene reaction kettle, add precursor samples for hydrothermal reaction, 100°C, 5h; wait for natural cooling to room temperature After that, the nickel foam was taken out, washed and dried to obtain Co 9 S 8 / NF samples. Let cool a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com