Flexible strain transducer based on carbon nanofiber yarn woven fabric and preparation method thereof

A technology of carbon nanofibers and strain sensors, applied in fabrics, fabric surface trimming, heating/cooling fabrics, etc., can solve the problems of sensor thickness and sensitivity coefficients, achieve high sensitivity coefficients, low energy consumption, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

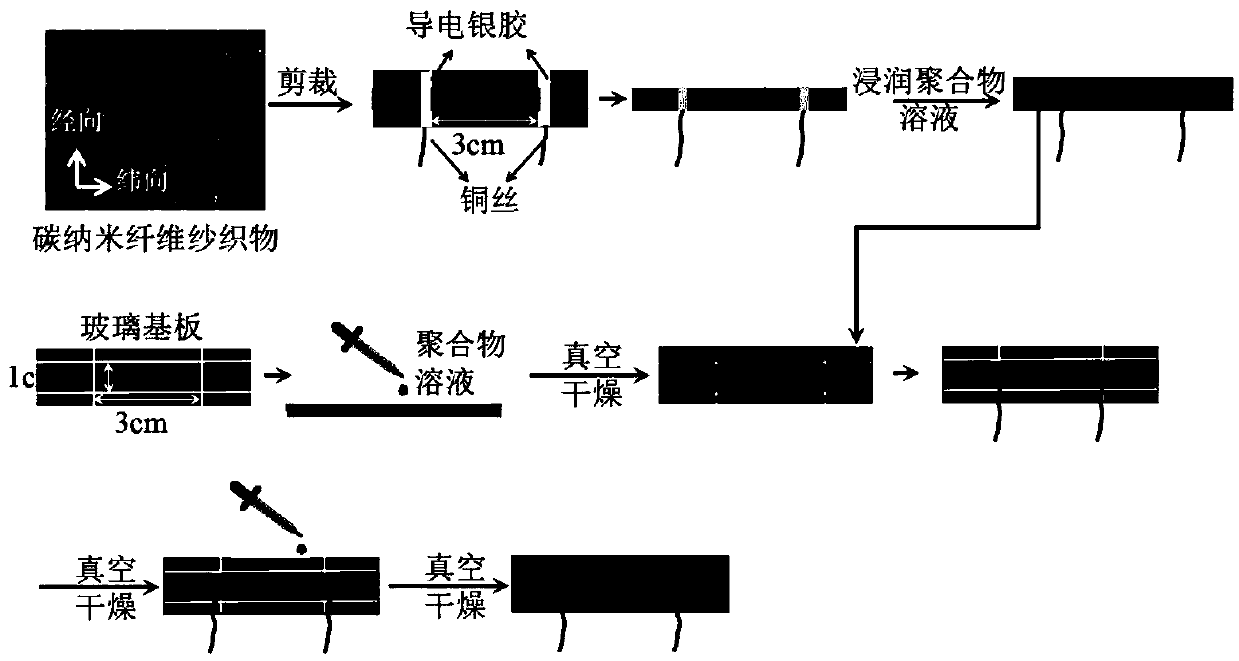

[0048] A method for preparing a flexible strain sensor based on carbon nanofiber yarn fabric, the steps are as follows:

[0049] (1) Preparation of carbon nanofiber yarn fabric:

[0050] (1.1) Utilize the multi-nozzle wet-electrospinning device to prepare polyacrylonitrile nanofiber bundles, and make polyacrylonitrile nanofiber yarns by combining and twisting;

[0051] (1.2) Sizing the polyacrylonitrile nanofiber yarn, the polyacrylonitrile nanofiber yarn after the above sizing is the weft yarn, and the polyacrylonitrile staple fiber yarn is the warp yarn for weaving to obtain the fabric, and then the fabric is desized and ironed Prepared nanofiber yarn woven fabric, wherein the warp density of the fabric is 380 / 10cm, the weft density is 100 / 10cm, and the fabric structure is plain weave;

[0052] (1.3) Pre-oxidize and carbonize the nanofiber yarn fabric to obtain the carbon nanofiber yarn fabric; the pre-oxidation is carried out under air atmosphere, the pre-oxidation heating...

Embodiment 2

[0066] A method for preparing a flexible strain sensor based on carbon nanofiber yarn fabric, the steps are as follows:

[0067] (1) Preparation of carbon nanofiber yarn fabric:

[0068] (1.1) Utilize the multi-nozzle wet-electrospinning device to prepare polyacrylonitrile nanofiber bundles, and make polyacrylonitrile nanofiber yarns by combining and twisting;

[0069] (1.2) Sizing the polyacrylonitrile nanofiber yarn, the polyacrylonitrile nanofiber yarn after the above sizing is the weft yarn, and the polyacrylonitrile staple fiber yarn is the warp yarn for weaving to obtain the fabric, and then the fabric is desized and ironed Prepared nanofiber yarn woven fabric, wherein the warp density of the fabric is 200 / 10cm, the weft density is 50 / 10cm, and the fabric structure is plain weave;

[0070] (1.3) Pre-oxidize and carbonize the nanofiber yarn fabric to obtain the carbon nanofiber yarn fabric; the pre-oxidation is carried out under air atmosphere, the pre-oxidation heating ...

Embodiment 3

[0077] A method for preparing a flexible strain sensor based on carbon nanofiber yarn fabric, the steps are as follows:

[0078] (1) Preparation of carbon nanofiber yarn fabric:

[0079] (1.1) Utilize the multi-nozzle wet-electrospinning device to prepare polyacrylonitrile nanofiber bundles, and make polyacrylonitrile nanofiber yarns by combining and twisting;

[0080] (1.2) Sizing the polyacrylonitrile nanofiber yarn, the polyacrylonitrile nanofiber yarn after the above sizing is the weft yarn, and the polyacrylonitrile staple fiber yarn is the warp yarn for weaving to obtain the fabric, and then the fabric is desized and ironed Prepared nanofiber yarn woven fabric, wherein the warp density of the fabric is 300 / 10cm, the weft density is 200 / 10cm, and the fabric structure is plain weave;

[0081] (1.3) Pre-oxidize and carbonize the nanofiber yarn fabric to obtain the carbon nanofiber yarn fabric; the pre-oxidation is carried out in air atmosphere, the pre-oxidation heating ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com