Recovery of thermal power plant dry capture co 2 Systems where process waste heat is used for heating

A thermal power plant and dry process technology, applied in heating systems, hot water central heating systems, household heating, etc., can solve problems such as different carbon capture reaction temperatures, achieve high-efficiency utilization, reduce impacts, and reduce comprehensive The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

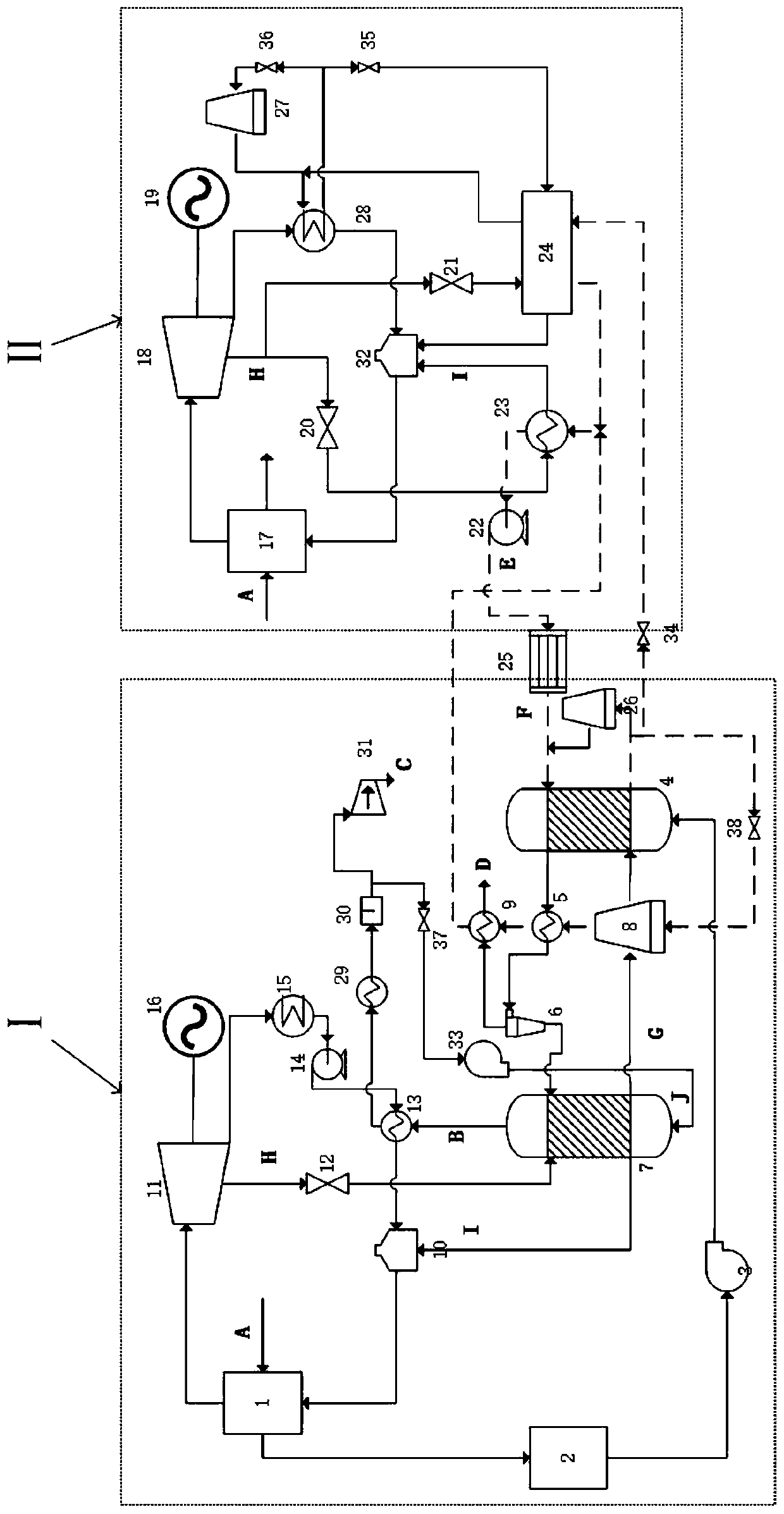

[0026] The system involved in the present invention is composed of a carbon capture unit and a steam extraction heat supply unit, and the two units are mainly coupled through the heat exchange between the heating network water and the carbonation reactor.

[0027] The carbon capture unit mainly consists of two parts: power generation subsystem 1 and carbon capture subsystem.

[0028] The flue gas generated by boiler combustion in power generation sub-system 1 is discharged into the atmosphere after passing through the flue gas treatment device, booster fan, carbonation reactor, preheater, cyclone separator, and flue gas heat exchanger;

[0029] The steam extracted by steam turbin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com