A Fully Assembled Segmented Buckling-Resistant Brace That Can Directly Replace the Inline Core

An anti-buckling support, a straight-line technology, applied in the direction of earthquake resistance, building types, protected buildings/shelters, etc., to achieve simple and fast repair work, improve efficacy and timeliness, and optimize post-earthquake repair work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

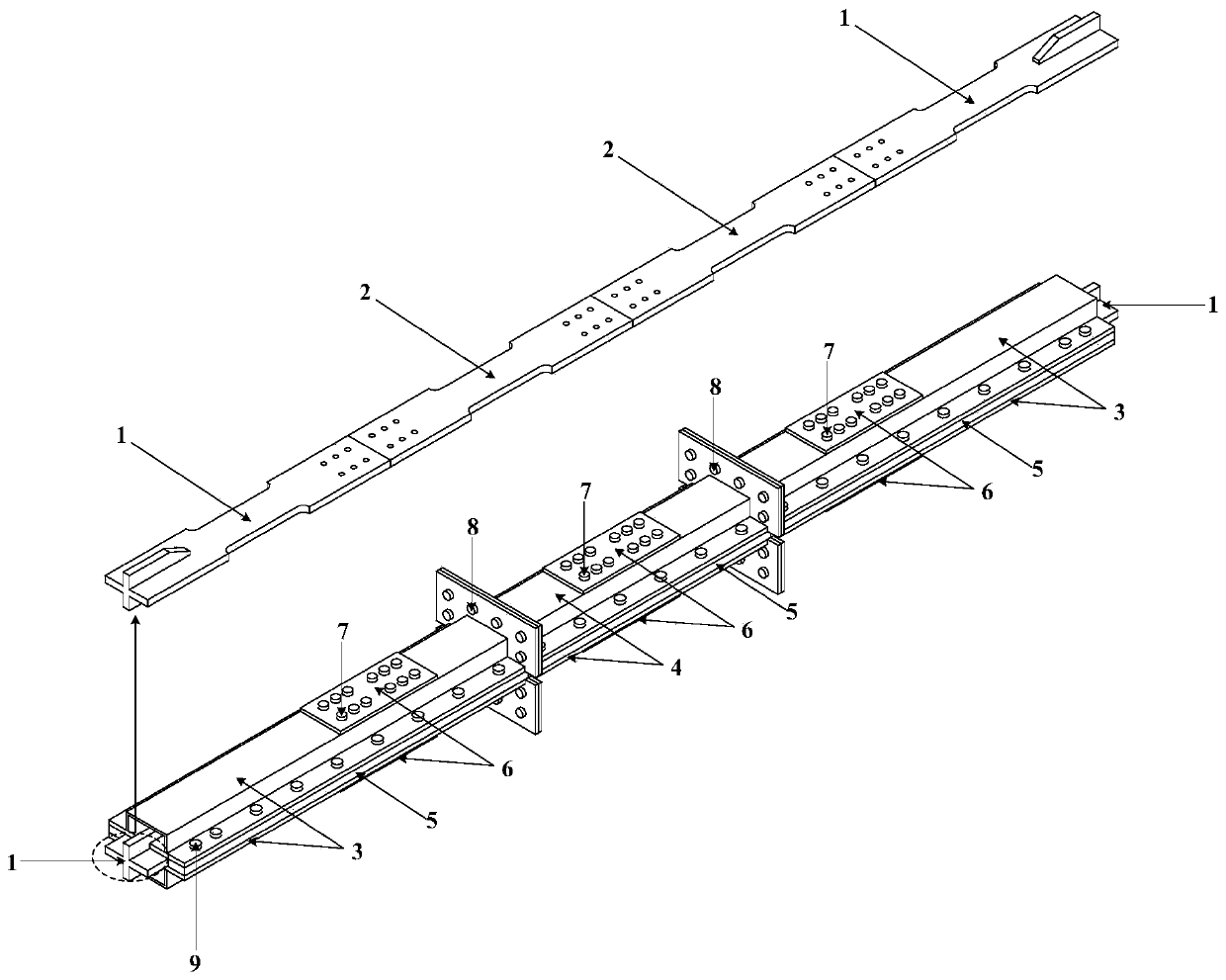

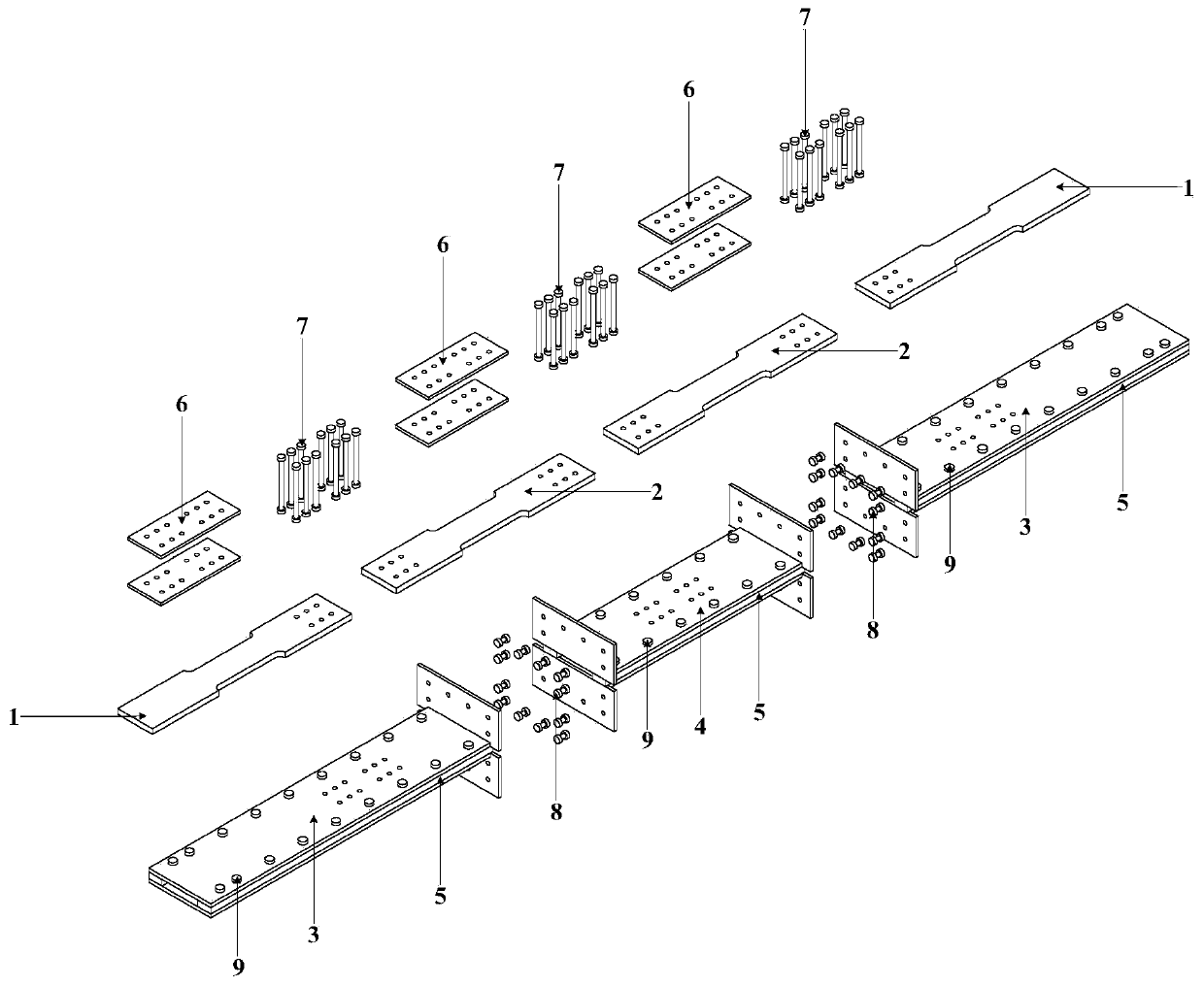

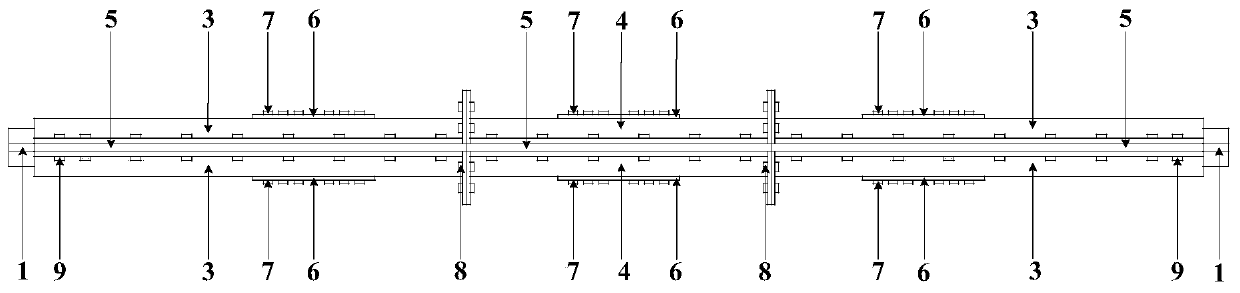

[0030] Attached below Figure 1-9 , detailing the implementation of this patent.

[0031] Such as Figure 1-9 As shown, a fully-assembled segmented buckling-resistant support that can directly replace the inline core includes the following components:

[0032] 1—— side segment one-line core component;

[0033] 2——The one-line core component in the middle section;

[0034] 3——The edge segment with flange plate protruding constraining member;

[0035] 4——Extruded restraint member in the middle section with flange;

[0036] 5 - backing plate;

[0037] 6——connection cover outside the inner core;

[0038] 7——The first high-strength bolt group;

[0039] 8——The second high-strength bolt group;

[0040] 9——The third high-strength bolt group;

[0041] 10——Assembled side segment peripheral restraint device unit;

[0042] 11——Assembled middle section peripheral restraint device unit;

[0043] 12——The end reinforcement area of the in-line inner core member of the side section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com